Degreaser for treating produced water of polymer flooding

A technology for effluent treatment and degreasing agent, which is applied in mining wastewater treatment, flocculation/sedimentation water/sewage treatment, grease/oily substance/float removal device, etc. Dual functions of milk and flocculation, excellent compatibility, the effect of increasing flocculation particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Degreaser AE 1 and its preparation method

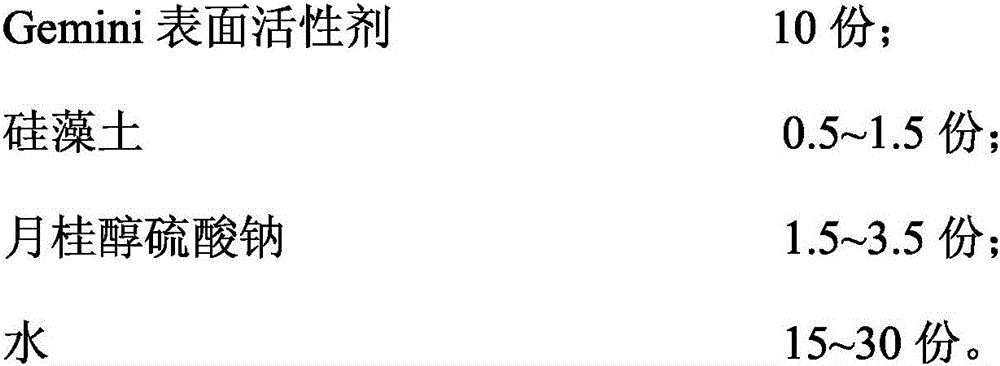

[0033] (1) Degreaser AE 1 The composition and its components are as follows:

[0034]

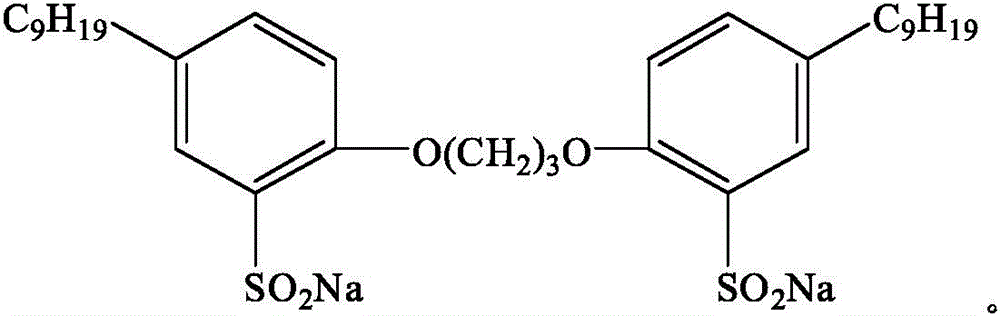

[0035] According to existing literature, the preparation method of described Gemini surfactant is as follows:

[0036]

[0037] (2) Degreaser AE 1 The preparation method is as follows:

[0038] ①Add 7.5 parts of water to the beaker, adjust the temperature to 46°C, slowly add 0.5 parts of diatomaceous earth, stir evenly, the stirring speed is 200rpm, and the stirring time is 10min;

[0039] ②Add 1.5 parts of sodium lauryl sulfate to the above beaker, adjust the temperature to 50°C, stir evenly, the stirring speed is 420rpm, and the stirring time is 20min;

[0040] ③ Adjust the temperature to 65°C, add 10 parts of Gemini surfactant to the above beaker, stir evenly, the stirring speed is 500rpm, and the stirring time is 38min;

[0041] ④The temperature is lowered to room temperature, slowly pour in 7.5 parts of water, st...

Embodiment 2

[0042] Embodiment 2: Degreaser AE 2 and its preparation method

[0043] (1) Degreaser AE 2 The composition and its components are as follows:

[0044]

[0045] According to existing literature, the preparation method of described Gemini surfactant is as follows:

[0046]

[0047] (2) Degreaser AE 2 The preparation method is as follows:

[0048] ①Add 12.5 parts of water to the beaker, adjust the temperature to 43°C, slowly add 0.8 parts of diatomaceous earth, stir evenly, the stirring speed is 250rpm, and the stirring time is 15min;

[0049] ②Add 2.0 parts of sodium lauryl sulfate to the above beaker, adjust the temperature to 58°C, stir evenly, the stirring speed is 380rpm, and the stirring time is 25min;

[0050] ③ Adjust the temperature to 62°C, add 10 parts of Gemini surfactant to the above beaker, stir evenly, the stirring speed is 600rpm, and the stirring time is 46min;

[0051] ④The temperature is lowered to room temperature, slowly pour in 12.5 parts of wate...

Embodiment 3

[0052] Embodiment 3: Degreaser AE 3 and its preparation method

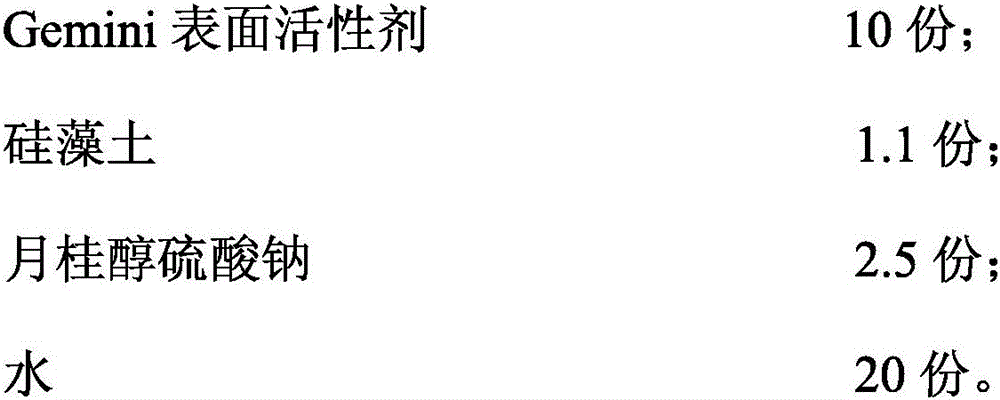

[0053] (1) Degreaser AE 3 The composition and its components are as follows:

[0054]

[0055] According to existing literature, the preparation method of described Gemini surfactant is as follows:

[0056]

[0057] (2) Degreaser AE 3 The preparation method is as follows:

[0058] ①Add 10 parts of water to the beaker, adjust the temperature to 40°C, slowly add 1.1 parts of diatomaceous earth, stir evenly, the stirring speed is 270rpm, and the stirring time is 25min;

[0059] ②Add 2.5 parts of sodium lauryl sulfate to the above beaker, adjust the temperature to 53°C, stir evenly, the stirring speed is 300rpm, and the stirring time is 32min;

[0060] ③ Adjust the temperature to 60°C, add 10 parts of Gemini surfactant to the above beaker, stir evenly, the stirring speed is 700rpm, and the stirring time is 30min;

[0061] ④The temperature is lowered to room temperature, slowly pour in 10 parts of water, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com