Tackifier, preparation method of tackifier and silicone rubber composition

A tackifier and mixture technology, applied in the direction of adhesives, polymer adhesive additives, adhesive additives, etc., can solve problems such as improving the bonding effect, and achieve good bonding effect, good stability, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a kind of preparation method of above-mentioned tackifier, comprises the following steps:

[0050] A) mixing organohydrogenpolysiloxane with a first solvent to obtain a first mixture;

[0051] B) mixing cyclic olefins, esters, catalysts and a second solvent to obtain a second mixture;

[0052] C) mixing and reacting the first mixture with the second mixture to obtain a tackifier;

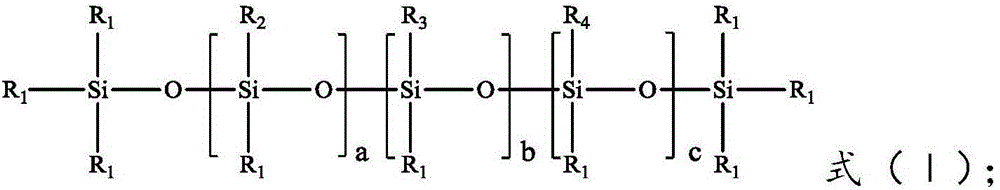

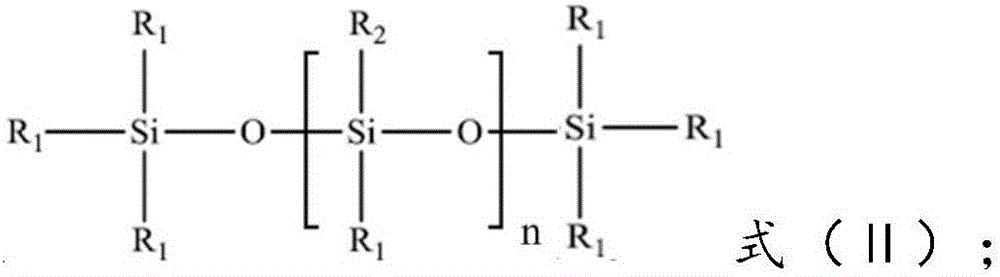

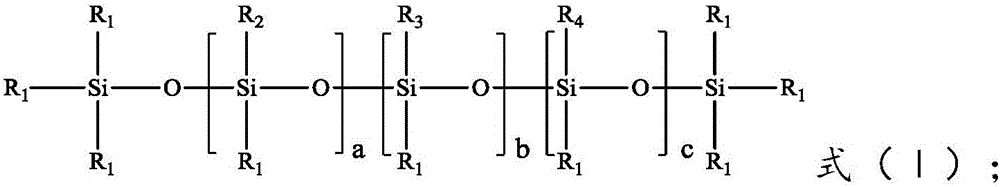

[0053] In the step A), the organohydrogenpolysiloxane has the structure shown in formula (II):

[0054]

[0055] Among them, R 1 selected from methyl, ethyl or phenyl; R 2 is hydrogen; 20≤n≤70;

[0056] In the step B), the cycloalkene is cyclopentene, cyclohexene, 3-vinylcyclohexene, 4-vinylcyclohexene, 5-dicycloheptene, 4-cyclooctene, 4 - vinylcyclooctene, 1,5-cyclooctadienyl or vinylnorbornene; said esters are methyl methacrylate, allyl methacrylate or glycidyl methacrylate.

[0057] According to the present invention, the organohydrogenpolysiloxan...

Embodiment 1

[0083] Toluene (113.1 g) and organohydrogenpolysiloxane (113.1 g, 0.05 mol) were charged into a 500 mL four-necked flask equipped with a reflux condenser, a thermometer, a dropping funnel, and a mechanical stirrer, heated to 80° C., and A mixture of vinyl norbornene (30.05g, 0.25mol), methyl methacrylate (25.03g, 0.25mol), Karstedt catalyst (0.34g, concentration 0.5%) and toluene (55.08g) was added dropwise within 30min. After the addition was completed, the reaction was carried out at a constant temperature of 80° C. for 3 h to obtain the reaction product. The reaction product was stirred and cooled to room temperature, added activated carbon (22.1 g) baked at 120 ° C for 3 h, stirred for 2 h, filtered; A transparent tackifier with a structure of formula (a);

[0084]

[0085] The bonding effect of the obtained tackifier of formula (a) was tested, and the test method was as follows: 100 parts of silicone rubber and 1 part of tackifier of formula (a) were mixed, and stirre...

Embodiment 2

[0088] Toluene (304.2g) and organohydrogenpolysiloxane (304.2g, 0.1mol) were charged into a 1L four-necked flask equipped with a reflux condenser, a thermometer, a dropping funnel and a mechanical stirrer, heated to 70°C, and A mixture of vinyl norbornene (48.08 g, 0.4 mol), allyl methacrylate (50.46 g, 0.4 mol), Karstedt catalyst (0.64 g, concentration 0.5%) and toluene (98.54 g) was added dropwise within 1 h, After the dropwise addition was completed, the reaction was carried out at a constant temperature of 70° C. for 3 h to obtain a reaction product. The reaction product was stirred and cooled to room temperature, added activated carbon (41.6g) baked at 150°C for 3h, stirred for 3h, and filtered; then the resulting material was desolventized at 130°C and a vacuum of 40mmHg to obtain 342.33g of A transparent tackifier with a formula (b) structure;

[0089]

[0090] According to the method of Example 1, the bonding effect of the tackifier of formula (b) on the silicone r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com