Preparation method of graphene oxide/nitrile rubber modified high-density polyethylene for 3D printing

A high-density polyethylene, nitrile rubber technology, applied in the direction of additive processing, etc., can solve the problems of easy aging, easy scratching, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

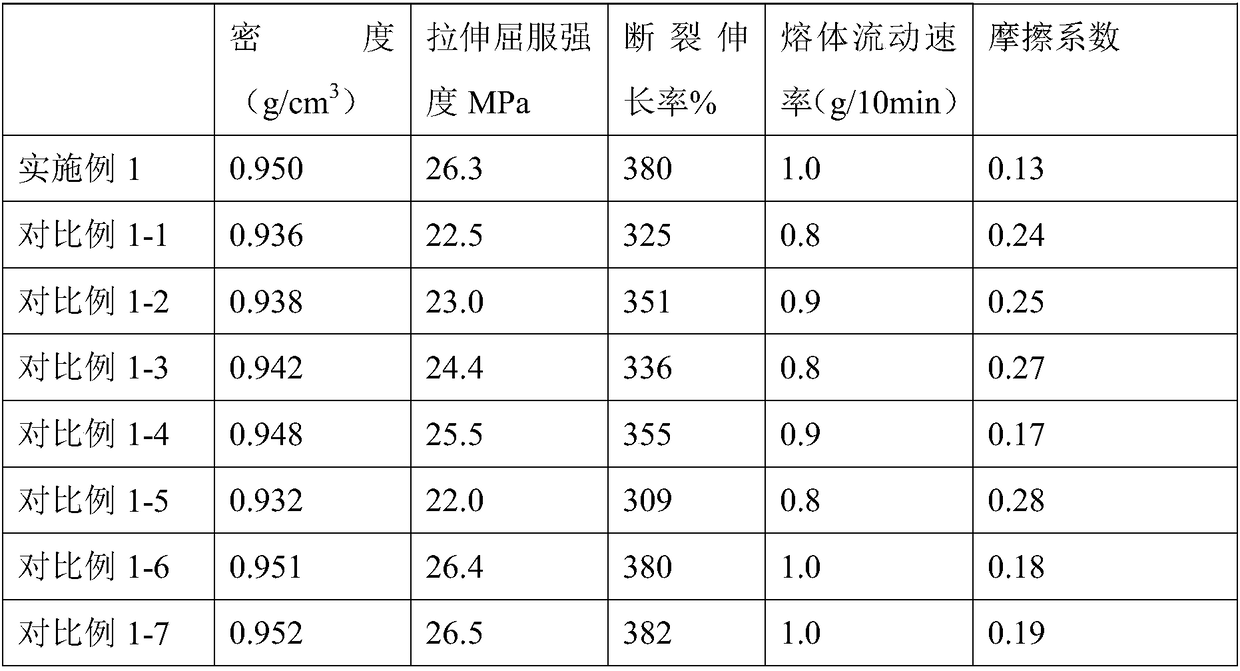

Examples

Embodiment 1

[0057] Embodiment 1, a kind of preparation method of graphene oxide / acrylonitrile-butadiene rubber modified high-density polyethylene for 3D printing, carries out following steps successively:

[0058] 1), modification of graphene oxide:

[0059] Add 200ml SOCl to 100mg graphene oxide 2 , 1ml dimethylformamide (DMF), reacted at 60°C for 36h, after the reaction was completed, the excess SOCl 2 and the solvent are removed by distillation at 90°C to obtain chlorinated graphene oxide;

[0060] Add 100mL of dimethylformamide solvent and 0.5g of octadecyltrimethylammonium chloride to the chlorinated graphene oxide obtained above, react at 110°C for 72h, filter the reaction product, and rinse the obtained filter cake with ethanol Suction filtration 3 times, each time the amount of ethanol is 30ml, to obtain modified graphene oxide.

[0061] 2), preparation of modified graphene oxide / powder nitrile rubber:

[0062] The modified graphene oxide obtained in step 1) and deionized wate...

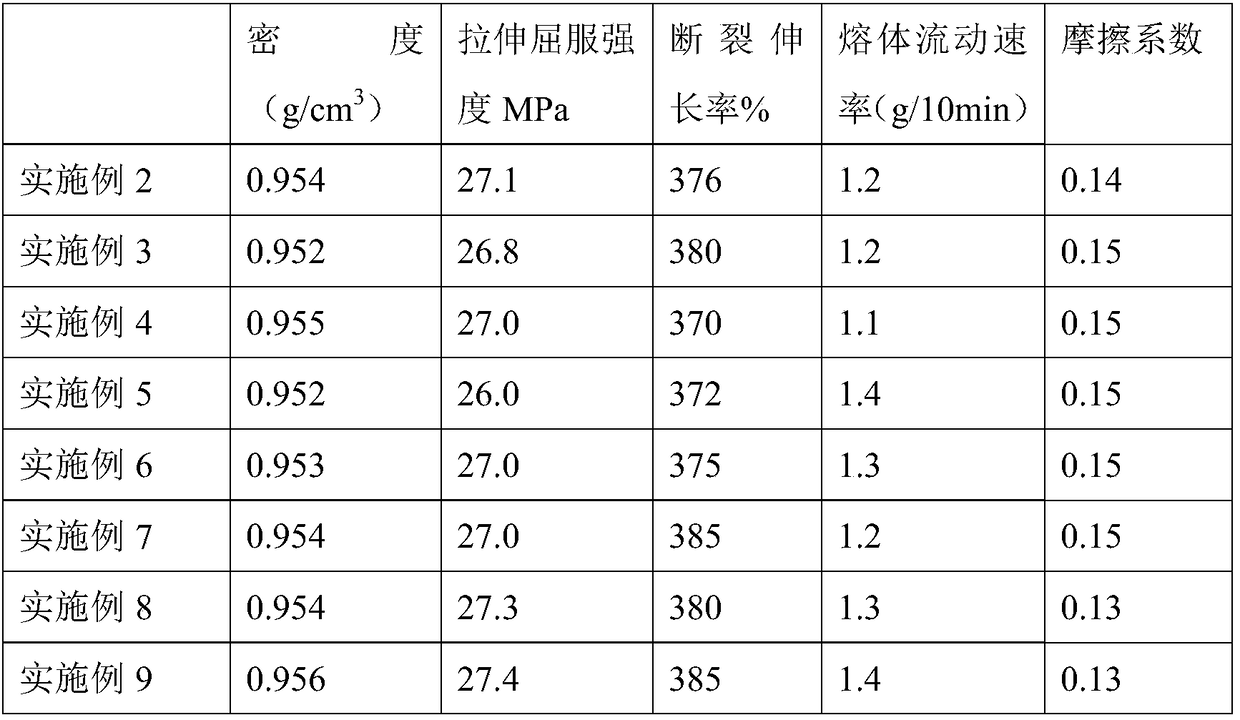

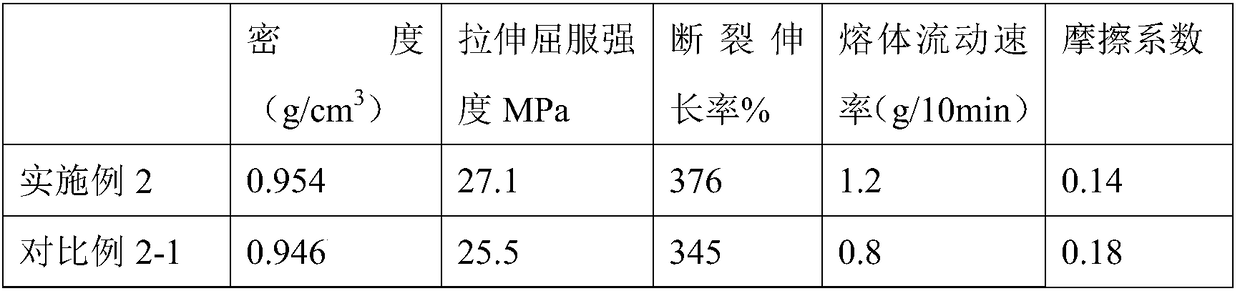

Embodiment 2

[0080] Embodiment 2, a kind of preparation method of graphene oxide / acrylonitrile-butadiene rubber modified high-density polyethylene for 3D printing, carries out following steps successively:

[0081] 1), modification of graphene oxide:

[0082] Add 200ml SOCl to 100mg graphene oxide 2, 2.5ml dimethylformamide (DMF), reacted at 80°C for 36h, after the reaction, the excess SOCl 2 and the solvent are removed by distillation at 90°C to obtain chlorinated graphene oxide;

[0083] Add 100mL DMF and 1.5g octadecyltrimethylammonium bromide to the chlorinated graphene oxide obtained above, react at 130°C for 108h, filter the reaction product, and wash the obtained filter cake with ethanol for 3 times, The amount of ethanol was 30ml to obtain modified graphene oxide.

[0084] 2), preparation of modified graphene oxide / powder nitrile rubber:

[0085] The modified graphene oxide obtained in step 1) and deionized water are dispersed in a high-speed mixer according to a mass ratio of ...

Embodiment 3

[0092] Embodiment 3, "polyethylene wax" in embodiment 2 is changed into " white oil ", all the other are equal to embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com