Fly ash modified high-efficient mercury removal method of dust remover and system thereof

A dust collector and modification technology, which is applied in the field of high-efficiency mercury removal by fly ash modification of dust collectors, can solve the problems of limited use effect, strong corrosiveness of modified reagents, and reduction of mercury emissions, and achieves an increase in the actual utilization rate, particle size reduction, etc. Good dispersion, the effect of reducing industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

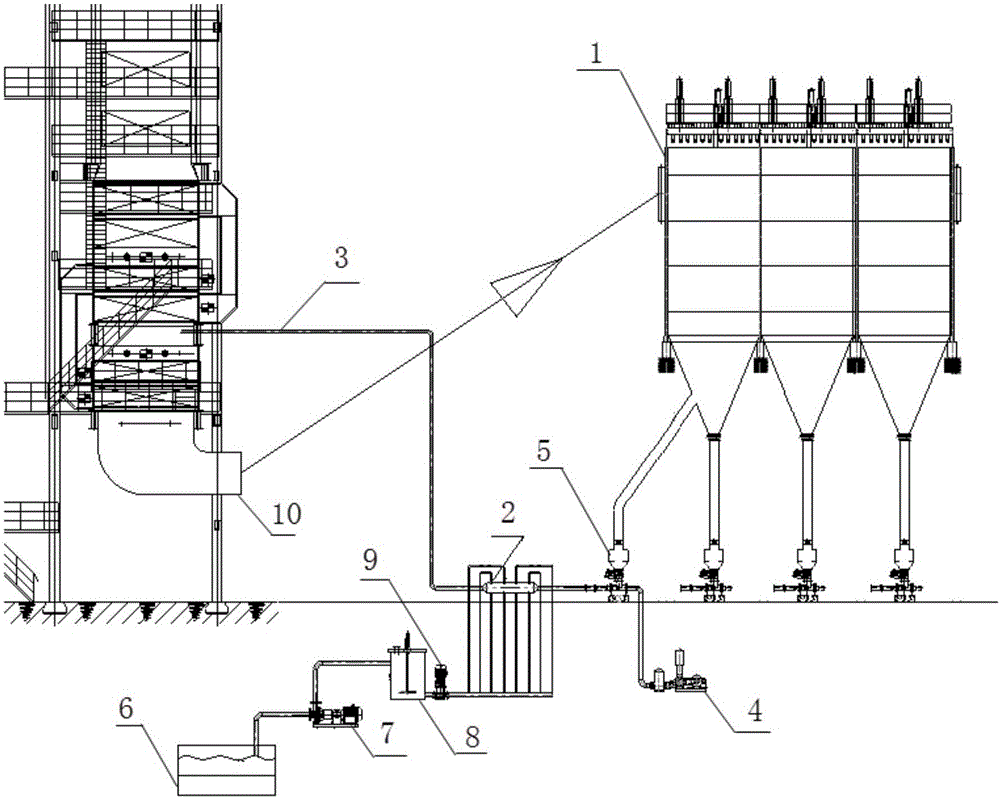

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

[0026] The invention provides a modified and efficient mercury removal method for dust collector fly ash, which comprises the following steps:

[0027] (1) The dust collector continuously captures the waste flue gas in the industrial area and processes the waste flue gas to obtain fly ash, which is transported through the cone bucket at the bottom of the dust collector;

[0028] (2) Using the dilute-phase pneumatic conveying method, the fly ash is continuously sprayed from the cone bucket at the bottom of the dust collector to the rear end of the economizer, and the injection air volume is 2.66-4.57m 3 / min, the total injection pressure is 9.8~14.7kpa; during the conveying process from the cone bucket to the rear end of the economizer, the fly ash passes through the ultrasonic atomization device with a modification reagent solution inside, and the fly ash and the modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com