Floatation and impurity removal method before tin backwashing and reselection operation of tin copper associated sulphide ore

A sulfide ore and pre-operation technology, applied in the field of tin-copper symbiotic sulfide ore beneficiation, can solve problems such as affecting the recovery rate of cassiterite gravity separation, increasing the difficulty of cassiterite gravity separation and separation, and poor specific gravity, so as to improve the sulfur removal effect and reduce The effect of low chemical consumption and running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

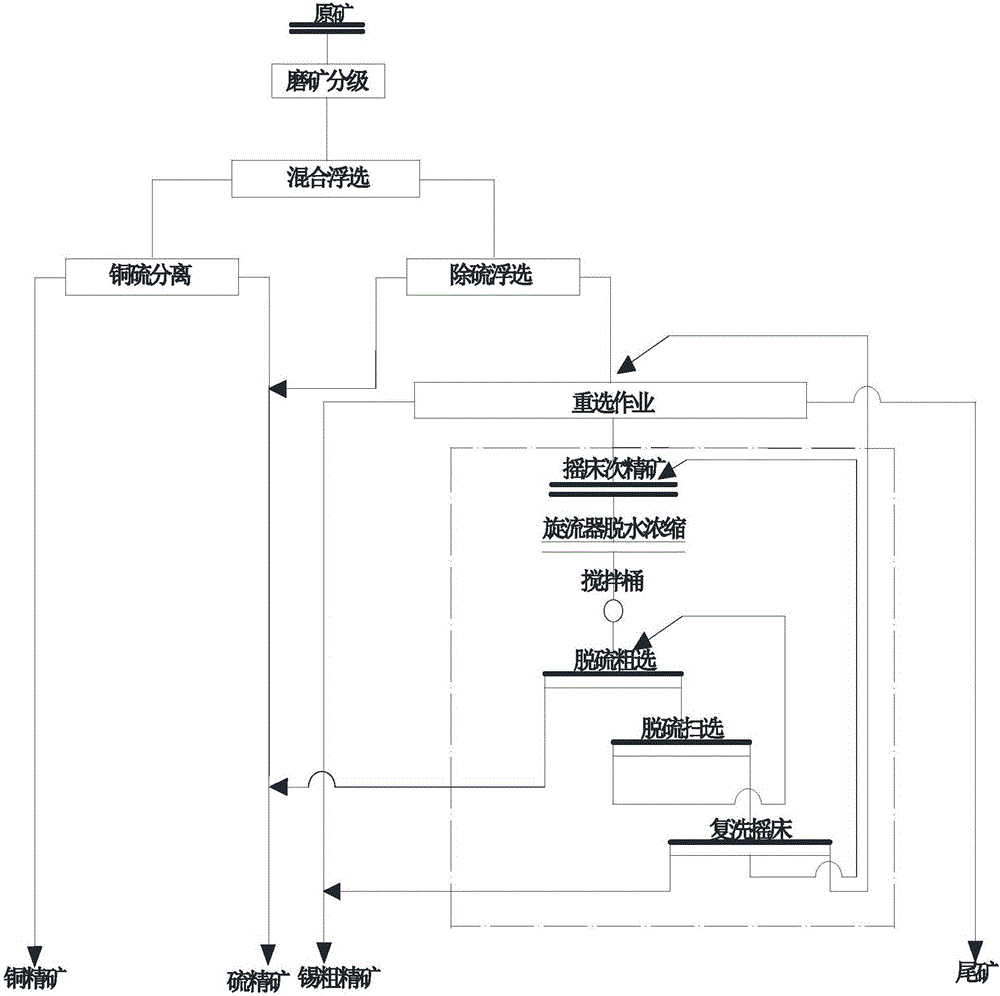

Method used

Image

Examples

Embodiment 1

[0018] A 160-ton / day process shaker secondary concentrate was selected from the beneficiation workshop of Yunnan Gejiu Yunxi Kafang Branch.

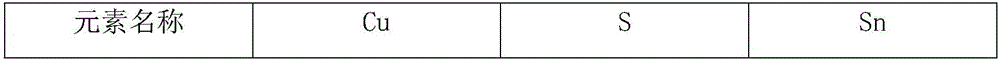

[0019] See Table 1 for the ore feeding elements of the rewashing bed:

[0020] Table 1. Analysis of ore feed elements in rewashing bed

[0021]

[0022]

[0023] The method for removing impurities by flotation before rewashing and re-election of tin in shaker sub-concentrate (tin-copper symbiotic sulfide ore) is as follows:

[0024] (1) Concentrate re-washed secondary concentrates with re-election cassiterite with a metal content of 50% and washed by a shaking table, and use a φ250 cyclone to concentrate and dehydrate, and the cyclone feed pressure is 1kg / cm 2 , the ore feeding concentration is 10%, and the ore discharge and sand concentration concentration is 25%;

[0025] (2) Sand settling for flotation desulfurization and impurity removal to remove coarse particles and large specific gravity pyrite concentrates; flotation impu...

Embodiment 2

[0029] A 600-ton / day symbiotic sulfide ore process shaker secondary concentrate was selected in the beneficiation workshop of Yunnan Gejiu Yunxi Kafang Branch.

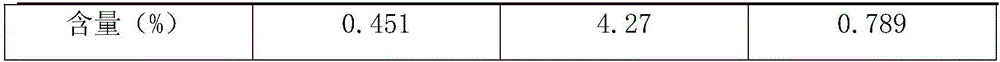

[0030] See Table 2 for the ore feeding elements of the rewashing bed:

[0031] Table 2. Analysis of ore feed elements in rewashing bed

[0032] element name Cu S sn content% 0.65 5.46 0.91

[0033] The method for removing impurities by flotation before rewashing and re-election of tin in shaker sub-concentrate (tin-copper symbiotic sulfide ore) is as follows:

[0034] (1) Concentrate re-washed sub-concentrates with a circulating metal content of 55% in gravity-selected cassiterite and washed by shaking tables, and use a φ250 cyclone to deslim the sub-concentrates in gravity-selected shaking tables. The ore feeding pressure of the device is 1kg / cm 2 , the ore feeding concentration is 12%, and the desliming tailings with a yield of 26.12% and the sand settling with a pulp concentration of 3...

Embodiment 3

[0039] The method for flotation and impurity removal before tin rewashing and gravity separation in tin-copper symbiotic sulfide ore is as follows:

[0040] (1) Concentrate re-washed sub-concentrates with re-election cassiterite recycling metal rate of 60%, coarse mineral particle size, large specificity, many combinations, poor monomer dissociation, and washed by shaking table, using φ250 spinner Concentrated and dehydrated by hydrocyclone, the ore feeding pressure of hydrocyclone is 1kg / cm 2 , the ore feeding concentration is 8%, and the ore discharge concentration is 20%;

[0041] (2) Sand settling for flotation desulfurization and impurity removal, removal of coarse particles and large specific gravity pyrite concentrates, and output of pyrite concentrates with arsenic content of 0.3-0.812% and sulfur content of more than 30% and anti-enrichment pyrite concentrates For tin tailings, flotation and impurity removal include a roughing and a sweeping operation. The roughing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com