Medium temperature frequency selective surface material and preparation method thereof

A frequency-selective surface and medium-temperature technology, applied in the field of aerospace materials, can solve problems such as shortage, achieve high transmittance, low process cost, and be conducive to industrial production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

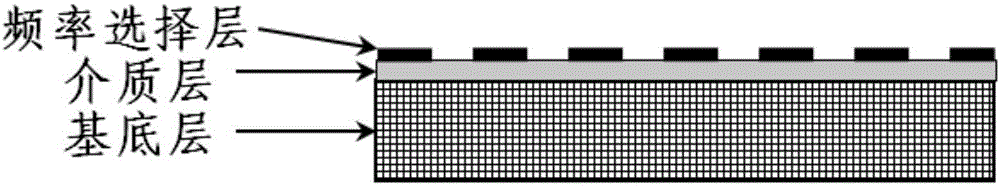

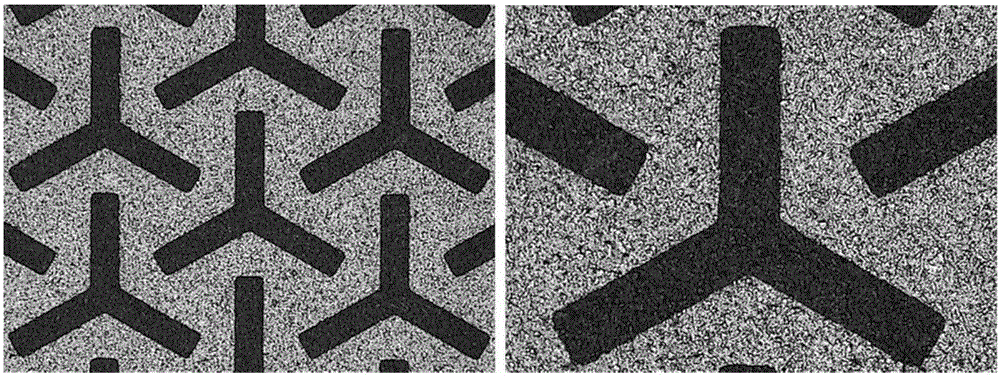

[0037] A kind of middle temperature frequency selective surface material of the present invention, its structural diagram is as figure 1 As shown, it includes base layer, intermediate dielectric layer and metal-type frequency selective surface layer from bottom to top. The amine film, the frequency selective surface layer is a metal nickel layer with a certain selective surface pattern; the thickness of the base layer is 2.82mm, the thickness of the intermediate dielectric layer is 0.075mm, and the thickness of the nickel layer is 3.05μm. The total thickness of the medium temperature frequency selective surface material plate sample is 3.00mm.

[0038] The preparation method of the medium-temperature frequency selective surface material of the present embodiment comprises the following steps:

[0039](1) Choose Philips B-grade plain weave quartz fiber cloth, and apply a polyimide resin solution with a concentration of 40wt% to the quartz fiber according to the mass ratio of t...

Embodiment 2

[0048] A kind of middle temperature frequency selective surface material of the present invention, its structural diagram is as figure 1 As shown, it includes base layer, intermediate dielectric layer and metal-type frequency selective surface layer from bottom to top. The amine film, the frequency selective surface layer is a metal silver layer with a certain selective surface pattern; the thickness of the base layer is 2.68mm, the thickness of the intermediate dielectric layer is 0.075mm, and the thickness of the silver layer is 2.42μm, the total thickness of the medium temperature frequency selective surface material plate sample It is 2.76mm.

[0049] The preparation method of the medium-temperature frequency selective surface material of the present embodiment comprises the following steps:

[0050] (1) Choose Feilihua B-grade plain weave quartz fiber cloth, and apply a polyimide resin solution with a concentration of 30wt% to the quartz fiber according to the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com