Silicate fluorescent ceramic with full-spectrum emission effect and preparation method thereof

A technology of fluorescent ceramics and silicate, which is applied in the field of silicate fluorescent ceramics and its preparation, can solve the problems of low color rendering index of white light LEDs, decreased light output efficiency of devices, weak absorption of excitation light, etc., and achieves high luminous efficiency, emission Wide wavelength range and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the powder in the embodiment of the present invention is direct ball milling of raw materials, but the preparation method of the mixed powder of the present invention is not limited to the above preparation method, and wet chemical methods such as sol-gel method and uniform precipitation well-known to those skilled in the art can also be used. synthesis.

[0037] The preparation method of the ceramic body in the embodiment of the present invention is dry pressing forming, but the present invention has no special limitation on the method of dry pressing forming, it can be a forming method well known to those skilled in the art. In the embodiment of the present invention, adopt Axial one-way pressurization is used for dry press forming, and axial two-way pressurization can also be used for dry press forming.

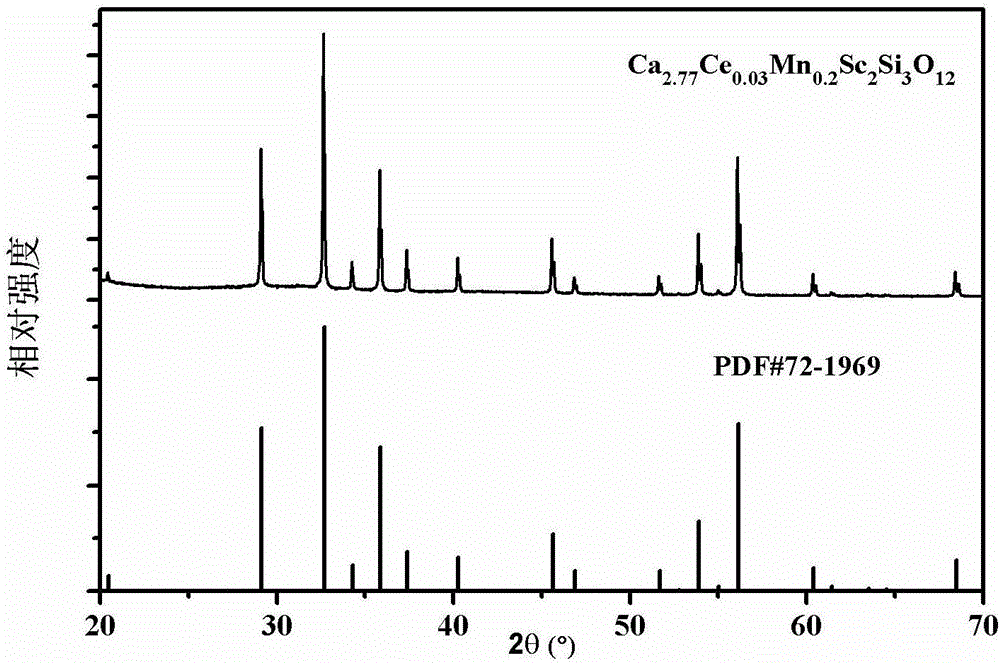

[0038] The ceramic phosphor can also be prepared by a two-step sintering method, that is, the powder is first sintered to obtain Ca 3-x-y...

Embodiment 1

[0043] Ca 2.969 Ce 0.001 mn 0.03 sc 2 Si 3 o 12 preparation of

[0044] Weigh CaCO according to stoichiometric ratio 3 : 14.903 g, Sc 2 o 3 : 6.895 g, SiO 2 : 9.013 g, CeO 2 : 0.087 g, MnCO 3 : 0.1724 g. Use zirconia balls and ball milling tanks to grind and mix the raw materials with absolute ethanol as the medium until the average particle size of the powder is less than 0.5 μm; dry and sieve the slurry obtained after ball milling; The sieved powder was first dry-pressed in an axial unidirectional pressure mold with a pressure of 20 MPa and a holding time of 2 minutes, and then pressed into a green body by cold isostatic pressing (pressure of 220 MPa and holding time of 2 minutes). Put the biscuit into a vacuum furnace for sintering: first, raise the temperature to 1000°C at 4°C / min, keep it for 5 hours, and decompose the carbonate; To 1600 ℃, keep warm for 10h, remove pores and densify. The vacuum sintered samples were placed in a hot-press sintering furnace f...

Embodiment 2

[0047] Ca 2.85 Ce 0.05 mn 0.1 sc 2 Si 3 o 12 preparation of

[0048] Weigh CaCO according to stoichiometric ratio 3 , Sc 2 o 3 , SiO 2 , CeO 2 and MnCO 3 , using zirconia balls and ball milling tanks, and using absolute ethanol as the medium to grind and mix the raw materials until the average particle size of the powder is less than 0.5 μm; the slurry obtained after ball milling is dried and sieved; then, an appropriate amount of The sieved powder is first dry-pressed in an axial unidirectional pressure mold with a pressure of 20 MPa and a holding time of 2 minutes, and then pressed into a green body by cold isostatic pressing (pressure of 220 MPa and holding time of 2 minutes). Put the biscuit into a vacuum furnace for sintering: first, raise the temperature to 1000°C at 4°C / min, keep it for 5 hours, and decompose the carbonate; To 1600 ℃, keep warm for 10h, remove pores and densify. The vacuum sintered samples were placed in a hot-press sintering furnace for ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com