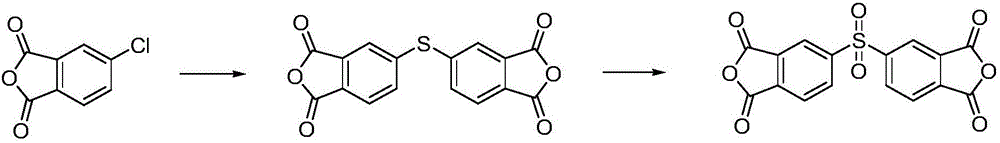

Preparation method of 3,3',4,4'-diphenyl sulfone tetracarboxylicdianhydride

A technology of diphenyl sulfone tetracarboxylic dianhydride and diphenyl sulfide tetracarboxylic dianhydride, which is applied in the preparation of monomer 3,3′,4,4′-diphenylsulfone tetracarboxylic dianhydride It can solve problems such as high requirements for reaction equipment, difficulty in purchasing catalysts, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 18.2g of 4-chlorophthalic anhydride, 120g of dimethyl sulfoxide, 0.77g of sulfur and 14.4g of sodium tert-butoxide to the reaction kettle, then raise the temperature to 40°C and drop in 11g of carbon disulfide (the molar ratio is: 4-chlorophthalic anhydride: carbon disulfide: Sulfur: sodium tert-butoxide: dimethyl sulfoxide = 1: 1.4: 0.03: 1.5: 15), after the dropwise addition is completed, the temperature is raised to 150 ° C to react until the raw materials are completely reacted, and part of the dimethyl sulfoxide is recovered under reduced pressure, and the remaining Add water, filter, wash with water, and dry to obtain 32.2 g of 3,3',4,4'-diphenylsulfide tetracarboxylic dianhydride, with a yield of 98.77%.

[0030] Add 16.3g 3,3',4,4'-diphenylsulfide tetracarboxylic acid diacid, 320g acetonitrile, 1.9g cerium ammonium nitrate, 0.9g tetrabutylammonium iodide and 160g water in the reaction kettle, heat up Add 16.2g potassium persulfate in batches to 40°C (molar r...

Embodiment 2

[0032] Add 18.2g of 4-chlorophthalic anhydride, 78g of dimethyl sulfoxide, 0.26g of sulfur and 11.5g of sodium tert-butoxide in the reactor, then add 8.4g of carbon disulfide dropwise to 40°C (the molar ratio is: 4-chlorophthalic anhydride: carbon disulfide : sulfur: sodium tert-butoxide: dimethyl sulfoxide = 1: 1.1: 0.01: 1.2: 10), after the dropwise addition is completed, the temperature is raised to 120 ° C to react until the raw materials are completely reacted, and part of the dimethyl sulfoxide is recovered under reduced pressure, and the remaining The mixture was added into water, filtered, washed with water, and dried to obtain 27.3g of 3,3',4,4'-diphenylsulfide tetracarboxylic dianhydride, with a yield of 83.74%.

[0033] In reactor, add 16.3g3,3',4,4'-diphenylsulfide tetracarboxylic acid diacid, 260g acetonitrile, 1.4g cerium ammonium nitrate, 0.2g tetrabutylammonium iodide and 130g water, be warmed up to Add 13.5g potassium persulfate in batches at 20°C (molar ratio...

Embodiment 3

[0035] Add 18.2g of 4-chlorophthalic anhydride, 156g of dimethyl sulfoxide, 1.3g of sulfur and 17.3g of sodium tert-butoxide to the reaction kettle, then raise the temperature to 40°C and drop in 13g of carbon disulfide (the molar ratio is: 4-chlorophthalic anhydride: carbon disulfide: Sulfur: sodium tert-butoxide: dimethyl sulfoxide = 1: 1.7: 0.05: 1.8: 20), after the dropwise addition is completed, the temperature is raised to 150 ° C to react until the raw materials are completely reacted, and part of the dimethyl sulfoxide is recovered under reduced pressure, and the remaining Add water, filter, wash with water, and dry to obtain 32.3 g of 3,3',4,4'-diphenylsulfide tetracarboxylic dianhydride, with a yield of 99.08%.

[0036]In reactor, add 16.3g3,3',4,4'-diphenylsulfide tetracarboxylic acid diacid, 400g acetonitrile, 2.7g ammonium cerium nitrate, 1.8g tetrabutylammonium iodide and 200g water, heat up to Add 16.2g potassium persulfate in batches at 60°C (molar ratio: 3,3′,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com