Lactic-acid-and-hydrogen-peroxide-coordination-soaking extracting method for corn starch

A technology of hydrogen peroxide and corn starch, which is applied in the field of corn starch extraction, can solve the problems of high process requirements, high cost, and low cost, and achieve the effects of reducing environmental pollution, reducing corrosion, and reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1 Materials and methods

[0038] 1.1 Materials and reagents

[0039] Corn: water content 12.6%, provided by the corn starch production workshop of Linghua Group Co., Ltd. (Jining, Shandong); hydrogen peroxide; other reagents are analytically pure.

[0040] 1.2 Instruments and equipment

[0041] YP201N electronic balance (Shanghai Jinghai Instrument Co., Ltd.), 303A2 electric heating constant temperature incubator (Nantong Hongda Experimental Instrument Co., Ltd.), DHG series electric heating constant temperature blast drying oven (Shanghai Xinmiao Medical Instrument Manufacturing Co., Ltd.), Western kitchen multi-functional crushing Machine (Boou Hardware Factory), HHS constant temperature water bath (Jiangsu Guosheng Experimental Instrument Factory), LXJ64-01 centrifuge (Hebei Wuqiao Electric Machinery Factory).

[0042] 1.3 Test method

[0043] 1.3.1 Lactic acid and hydrogen peroxide synergistic soaking process

[0044] Lactic acid and hydrogen peroxide synergisti...

Embodiment 2

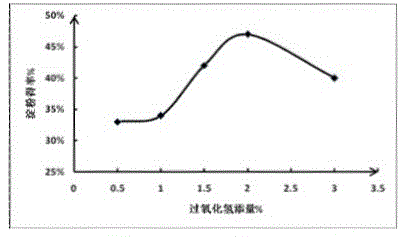

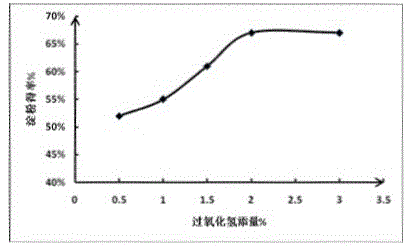

[0050] ① Accurately weigh 40g of corn, under the conditions of initial lactic acid concentration of 0.6%, soaking in lactic acid for 16 hours, hydrogen peroxide for 20 hours, and normal temperature, adjust the pH to 8 and then soak. Add hydrogen peroxide to the soaking solution at a hydrogen peroxide level of 3%. The effect of the amount of hydrogen peroxide on the yield of corn starch is as follows: figure 1 As shown, it can be seen that the yield of starch increases continuously with the increase of the amount of hydrogen peroxide, and when the amount of hydrogen peroxide increases to 2%, the yield of corn starch decreases.

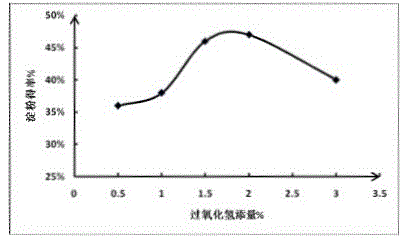

[0051] ② Accurately weigh 40g of corn, soak it under the conditions of initial lactic acid concentration of 0.6%, soaking in lactic acid for 16 hours, hydrogen peroxide action time of 20 hours, and normal temperature, and then use 0.5%, 1%, 1.5%, 2%, and 3% hydrogen peroxide respectively. Add hydrogen peroxide to the soaking solution. The effect of th...

Embodiment 3

[0057] (1) Effect of initial lactic acid concentration on starch yield

[0058] Accurately weigh 40g of corn, soak in lactic acid for 16 hours, and soak at a temperature of 50±2°C. Concentration Add lactic acid to the soaking liquid, the concentration of hydrogen peroxide is 2%, the soaking conditions are the same as in Example 2, ④, the weight ratio of corn to lactic acid solution and hydrogen peroxide is 1:1.5 respectively. The effect of initial lactic acid concentration on the yield of corn starch is as follows: Figure 6 It was shown that with the increase of the initial lactic acid concentration, the starch yield continued to increase, and when the initial lactic acid concentration increased to 0.6%, the corn starch yield began to decrease instead. This is because lactic acid can promote the softening and swelling of corn protein, maintain magnesium ions and calcium ions in the solution, accelerate water entry into corn kernels, and promote the separation of starch and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com