A kind of environment-friendly solvent-free impregnation resin and preparation method thereof

An impregnated resin and solvent-free technology, which is applied in the field of environment-friendly solvent-free impregnated resin and its preparation, can solve the problems of acid anhydride equipment and atmospheric side effects, unfavorable resin storage stability, failure to meet environmental protection requirements, etc., and achieve an environment-friendly Protection, excellent electrical properties, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

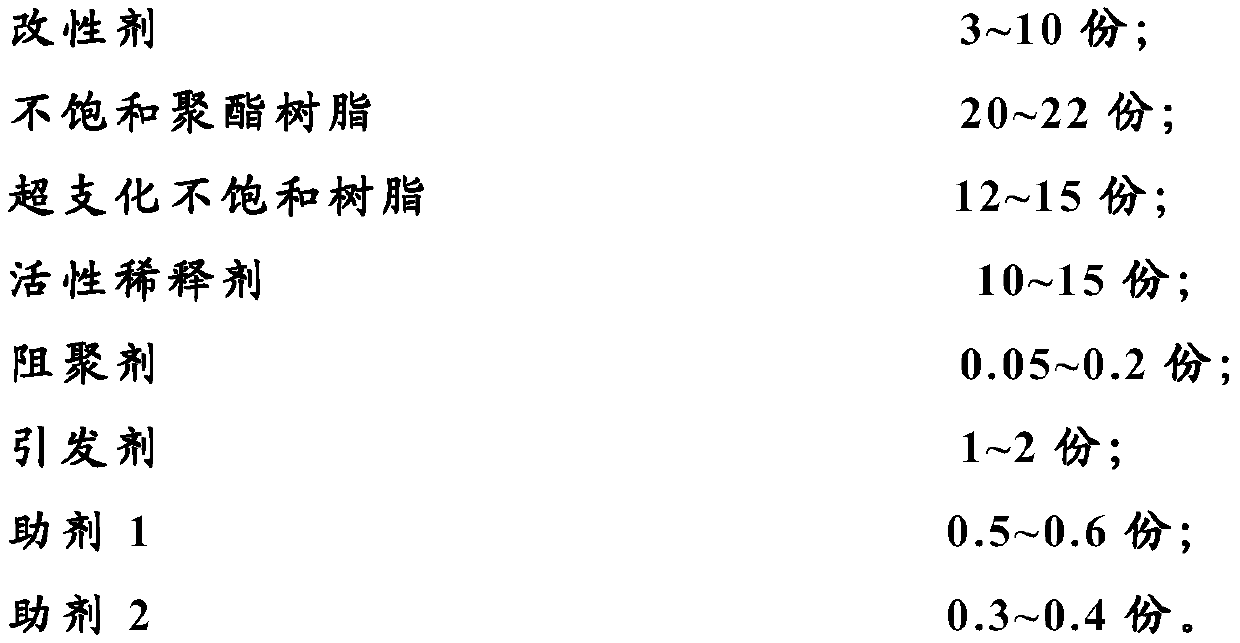

Method used

Image

Examples

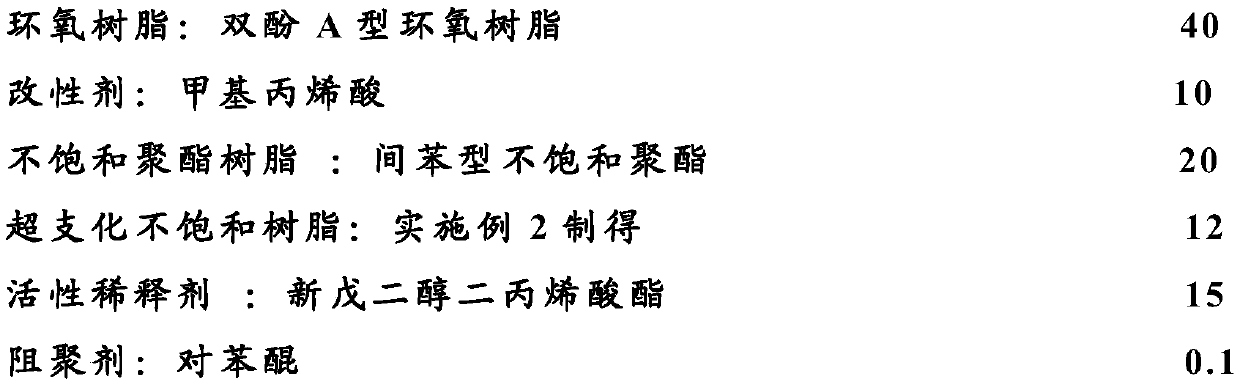

Embodiment 1

[0033] Add 134g of 1,1,1-trimethylolpropane and 134g of succinic anhydride into a three-necked flask, add 0.05g of catalyst p-toluenesulfonic acid, and under nitrogen protection, stir and heat up to 60°C for about 1-3 hours. Vacuumize at 80-100°C (vacuum degree 0.01-0.09MPa), add 25ml of toluene, heat up to toluene reflux, separate the water and toluene produced by the reaction, then raise the temperature to 180°C for 3-6 hours, cool down to room temperature and add 142g Acrylic acid, 1g H 2 SO 4 , 0.05g hydroquinone, stirred and reacted at 120°C for 5-6 hours, dehydrated and recovered the organic solvent at 100-120°C (vacuum degree 0.01-0.09MPa), and dried in vacuum to obtain a hyperbranched unsaturated resin.

Embodiment 2

[0035] Add 134g of 1,1,1-trimethylolpropane and 402g of 2,2-dimethylol propionic acid into a three-necked flask, add 0.06 catalyst p-toluenesulfonic acid, and stir and heat up to 120°C under nitrogen protection About 3-4 hours. Vacuum at 80-100°C (vacuum degree 0.01-0.09MPa), add 25ml of toluene, heat up to toluene reflux, separate the water and toluene produced by the reaction, then raise the temperature to 180°C for 4-6 hours, cool to room temperature and add 142g Acrylic acid, 0.8gH 2 SO 4 , 0.04 hydroquinone, stirred and reacted in a water bath at 120°C for 5-6 hours, vacuumized at 100-120°C (vacuum degree 0.01-0.09MPa) to dehydrate and recover the organic solvent, and vacuum-dried to obtain a hyperbranched unsaturated resin.

Embodiment 3

[0037] Add 134g of 1,1,1-trimethylolpropane and 192g of trimellitic anhydride into a 100ml three-necked flask, add 0.04g of catalyst p-toluenesulfonic acid, and stir to raise the temperature to 140°C for about 3-5 Hour. Vacuumize at 80-100°C (vacuum degree 0.01-0.09MPa), add 30ml of toluene, heat up to toluene reflux, separate the water and toluene produced by the reaction, then heat up to 180°C and reflux for 4-5 hours, cool to room temperature and add 142g acrylic acid, 1gH 2 SO 4, 0.05g hydroquinone, stirred and reacted at 120°C for 5-6 hours, dehydrated and recovered the organic solvent at 100-120°C (vacuum degree 0.01-0.09MPa), and dried in vacuum to obtain a hyperbranched unsaturated resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com