High-modulus asphalt additive

An asphalt additive and high modulus technology, applied in the field of asphalt modifiers, can solve problems affecting large-scale popularization and application, limited reserves of natural asphalt, etc., and achieve low price, increased compatibility, and good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

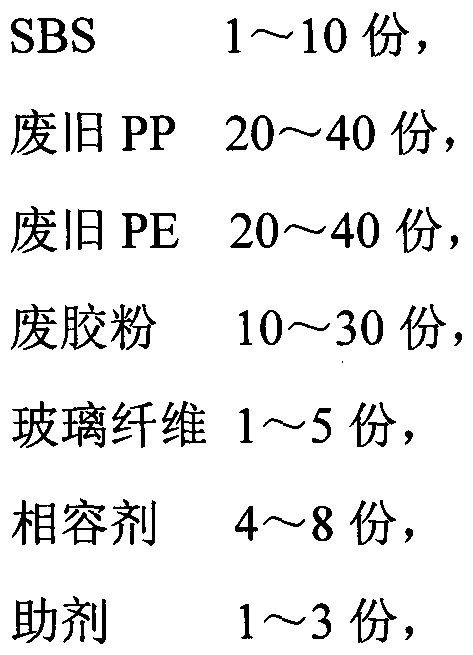

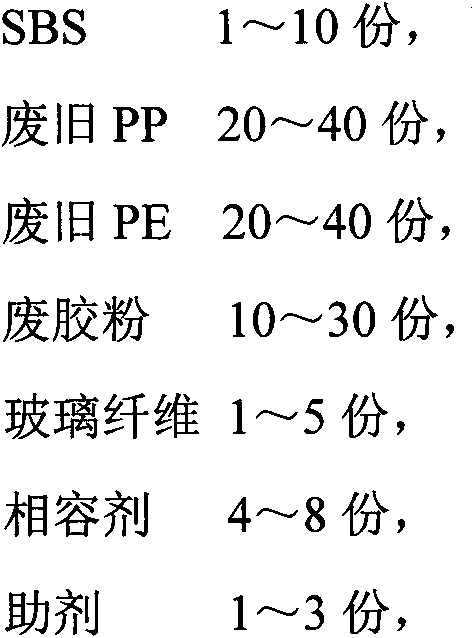

[0029] A high modulus asphalt additive, the components and weight parts are as follows:

[0030] SBS 5Kg,

[0031] Used PP 30Kg,

[0032] 30Kg of waste PE,

[0033] 25Kg of waste rubber powder,

[0034] Glass fiber 3Kg,

[0035] Maleic anhydride grafted SBS 1Kg,

[0036] Maleic anhydride grafted polypropylene 2Kg,

[0037] Maleic anhydride grafted polyethylene 2Kg,

[0038] Waste gear oil 0.5Kg,

[0039] Silane coupling agent 0.1Kg,

[0040] 2,6-tertiary butyl-4-methylphenol 0.5Kg,

[0041] Dioctyl phthalate 0.9Kg,

[0042] The preparation method of the high modulus asphalt additive of this embodiment includes the following steps:

[0043] (1) Accurately weigh SBS, waste PP, waste PE, waste rubber powder and other compatibilizers and various additives, add them to the stirring device in turn, and stir at room temperature for 10 minutes to prepare a mixture;

[0044] (2) Add glass fiber to the mixture, stir for 1 min, and then use a twin-screw extruder to extrude and pelletize to obtain high modul...

Embodiment 2

[0047] A high modulus asphalt additive, the components and weight parts are as follows:

[0048] SBS 3Kg,

[0049] Used PP 35Kg,

[0050] 35Kg of waste PE,

[0051] 13Kg of waste rubber powder,

[0052] Glass fiber 5Kg,

[0053] Maleic anhydride grafted SBS 1Kg,

[0054] Maleic anhydride grafted polypropylene 3Kg,

[0055] Maleic anhydride grafted polyethylene 3Kg,

[0056] Silane coupling agent 0.2Kg,

[0057] 2,6-tertiary butyl-4-methylphenol 0.8Kg,

[0058] Dioctyl phthalate 1Kg,

[0059] The preparation method of the high modulus asphalt additive in this embodiment is the same as that of Example 1.

[0060] The softening point of the high modulus asphalt additive prepared in Example 2 was tested and it was 82.1, which proved that its high modulus performance was good. The high modulus asphalt additive prepared in this embodiment is added to the asphalt mixture at 0.4% of the total mass of the asphalt mixture, and the dynamic modulus of the asphalt mixture is tested. The addition of the add...

Embodiment 3

[0062] A high modulus asphalt additive, the components and weight parts are as follows:

[0063] SBS 10Kg,

[0064] 25Kg of waste PP,

[0065] 20Kg of waste PE,

[0066] Waste rubber powder 30Kg,

[0067] Glass fiber 5Kg,

[0068] Maleic anhydride grafted SBS 2Kg,

[0069] Maleic anhydride grafted polypropylene 2Kg,

[0070] Maleic anhydride grafted polyethylene 2Kg,

[0071] Silane coupling agent 0.2Kg,

[0072] Bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide 0.8Kg,

[0073] Dioctyl phthalate 2Kg,

[0074] The preparation method of the high modulus asphalt additive in this embodiment is the same as that of Example 1.

[0075] The softening point of the high modulus asphalt additive prepared in Example 3 was tested and it was greater than 90, which proved that its high modulus performance was good. The high modulus asphalt additive prepared in this embodiment is added to the asphalt mixture at 0.4% of the total mass of the asphalt mixture, and the dynamic modulus of the asphalt mixture is test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com