Environment-friendly thermal-sublimation coating material

A coating material and thermal sublimation technology, applied in coatings, starch coatings, etc., can solve problems such as visual effects, vivid colors, image fidelity effects, complex preparation processes, and poor color clarity, and achieve solid Excellent color, simple manufacturing process, and high transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

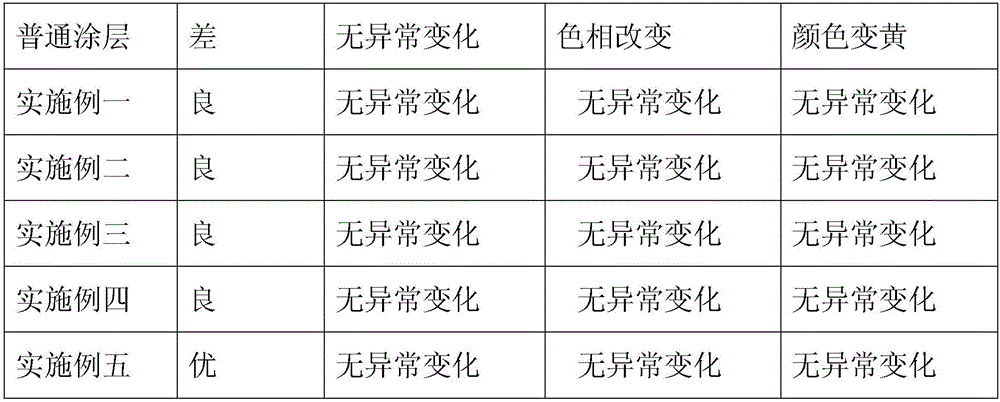

Examples

Embodiment 1

[0016] The component ratios used are: 20 parts carboxymethyl cellulose, 5 parts starch, 10 parts polyacrylamide, 10 parts polysaccharides and polysaccharide derivatives, 15 parts polycitric acid and polyethylene glycol-citric acid copolymer, two parts 8 parts of silicon oxide, 5 parts of barium sulfate, 5 parts of aluminum oxide, 4 parts of titanium dioxide, 5 parts of kaolin, 8 parts of calcium carbonate, 3 parts of bentonite powder, and 1 part of nano silver ion powder.

[0017] The preparation method of this embodiment includes the following steps:

[0018] A. Mix carboxymethyl cellulose, starch, polyacrylamide, polysaccharides and polysaccharide derivatives, polycitric acid, polyethylene glycol-citric acid copolymer, silicon dioxide, and then add them to the mixer for mixing and mixing The temperature of the machine is 75°C and the mixing time is 30 minutes to obtain mixture A;

[0019] B. Cool the mixture A to room temperature and add it to the mixer, then add barium sulfate, a...

Embodiment 2

[0023] The component ratios used are: 40 parts carboxymethyl cellulose, 15 parts starch, 18 parts polyacrylamide, 20 parts polysaccharides and polysaccharide derivatives, 25 parts polycitric acid and polyethylene glycol-citric acid copolymer, two parts 15 parts of silicon oxide, 10 parts of barium sulfate, 10 parts of aluminum oxide, 12 parts of titanium dioxide, 12 parts of kaolin, 17 parts of calcium carbonate, 10 parts of bentonite powder, and 4 parts of nano silver ion powder.

[0024] The preparation method of this embodiment includes the following steps:

[0025] A. Mix carboxymethyl cellulose, starch, polyacrylamide, polysaccharides and polysaccharide derivatives, polycitric acid, polyethylene glycol-citric acid copolymer, silicon dioxide, and then add them to the mixer for mixing and mixing The temperature of the machine is 90℃, and the mixing time is 50min to obtain mixture A;

[0026] B. Cool the mixture A to room temperature and add it to the mixer, then add barium sulfat...

Embodiment 3

[0030] The component ratios used are: 25 parts of carboxymethyl cellulose, 8 parts of starch, 11 parts of polyacrylamide, 12 parts of polysaccharides and polysaccharide derivatives, 17 parts of polycitric acid and polyethylene glycol-citric acid copolymer, two parts 9 parts of silicon oxide, 6 parts of barium sulfate, 6 parts of aluminum oxide, 6 parts of titanium dioxide, 6 parts of kaolin, 9 parts of calcium carbonate, 4 parts of bentonite powder, and 2 parts of nano silver ion powder.

[0031] The preparation method of this embodiment includes the following steps:

[0032] A. Mix carboxymethyl cellulose, starch, polyacrylamide, polysaccharides and polysaccharide derivatives, polycitric acid, polyethylene glycol-citric acid copolymer, silicon dioxide, and then add them to the mixer for mixing and mixing The temperature of the machine is 80℃, the mixing time is 35min, and the mixture A is obtained;

[0033] B. Cool the mixture A to room temperature and add it to the mixer, then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com