Anti-high temperature oxidation long-acting antirust composite epoxy powder paint for automobile chassis and preparation method thereof

A technology for resisting high temperature oxidation and automobile chassis, applied in powder coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of film flatness to be improved, short protection period, high construction equipment requirements, and achieve uniform and stable rust prevention. Good effect, heat resistance and wear resistance, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

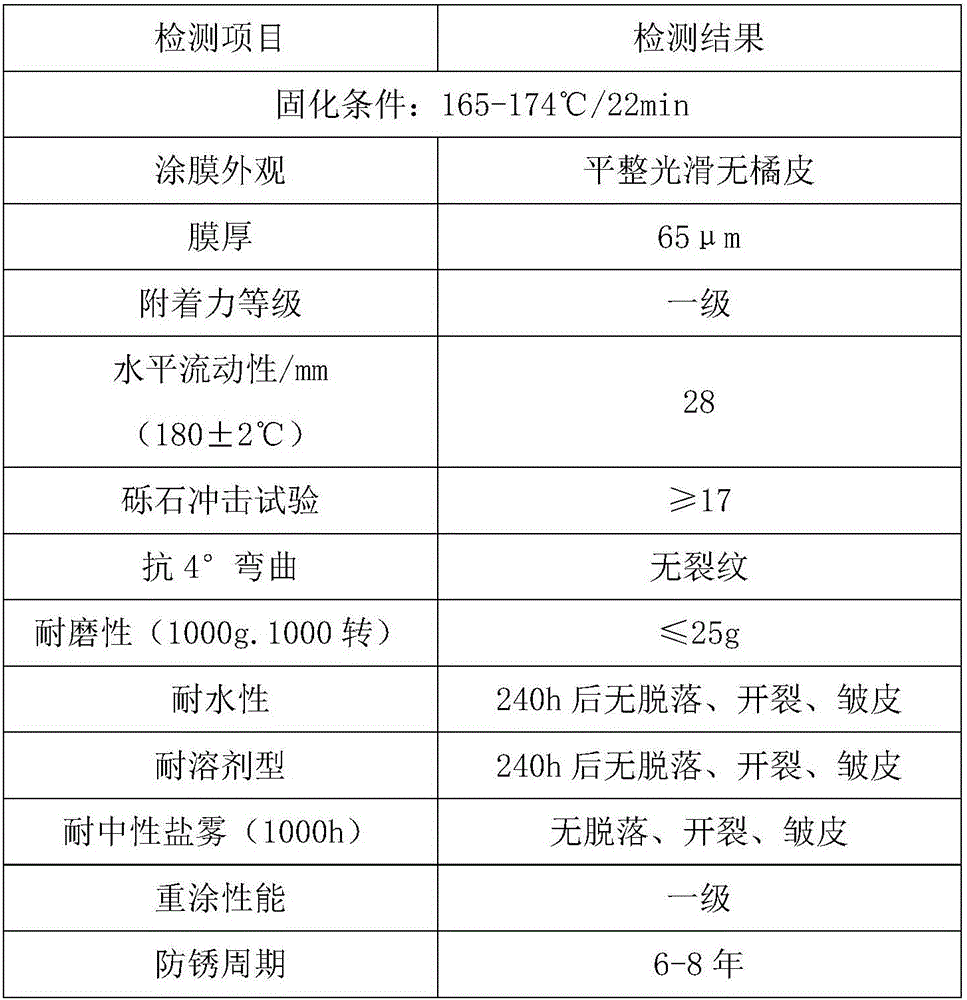

Image

Examples

Embodiment Construction

[0014] A high-temperature oxidation-resistant long-term anti-rust composite epoxy powder coating for automobile chassis, the coating is made of the following raw materials in parts by weight: cresol novolac epoxy resin 30, epoxy acrylic resin 12, carboxyl-terminated saturated polyester resin 10. Polyether diamine 3, phenolic curing agent 20, aluminum tripolyphosphate / polymethyl methacrylate microspheres 10, carborane acid 0.1×10 -6 , pyrrole monomer 4, azobisisobutyronitrile 0.1, graphene 0.01, concentration of 30% potassium persulfate solution 0.5, benzoin 0.6, antioxidant 0.5, brightener 0.8, deionized water 4.

[0015] Wherein the aluminum tripolyphosphate / polymethyl methacrylate microspheres are made of the following raw materials in parts by weight: aluminum tripolyphosphate 4, methyl methacrylate 5, divinylbenzene 2, dibenzoyl peroxide 0.4, Deionized water 20, absolute ethanol 12, sodium lauryl sulfate 0.1, the preparation method is:

[0016] (1) First put sodium lauryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com