A kind of emulsifier and its preparation method and application

A technology of emulsifier and surfactant, which is applied in the field of emulsifier and its preparation, can solve the problems of insufficient cleaning performance, dirty cleaning of equipment surface, uneven dyeing of fabrics, etc., and achieve uniform microscopic particle size distribution and good cleaning effect , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

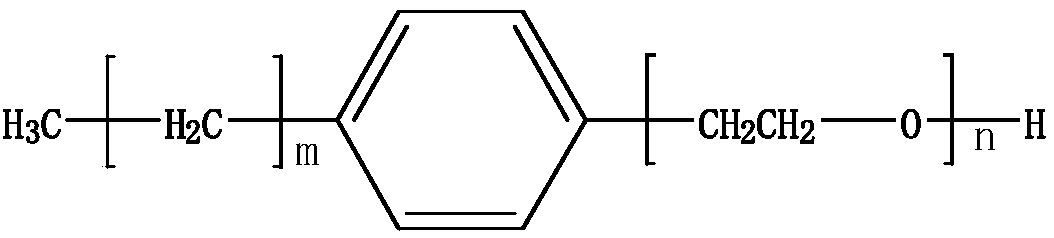

Method used

Image

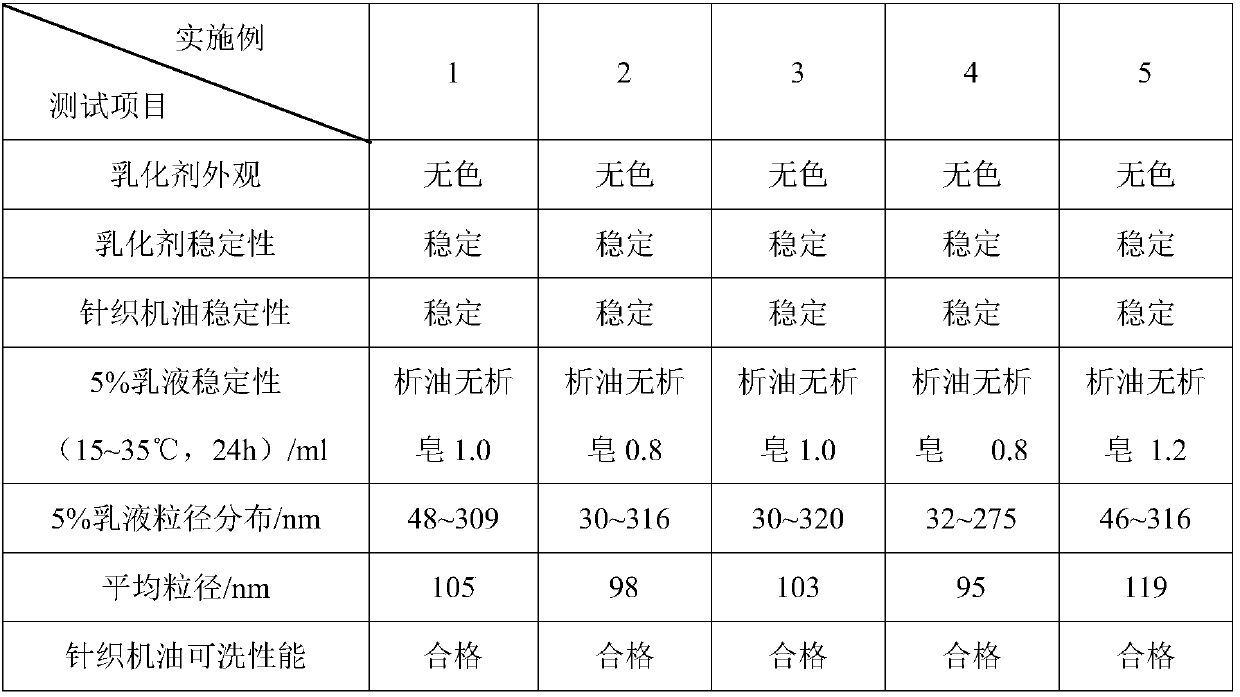

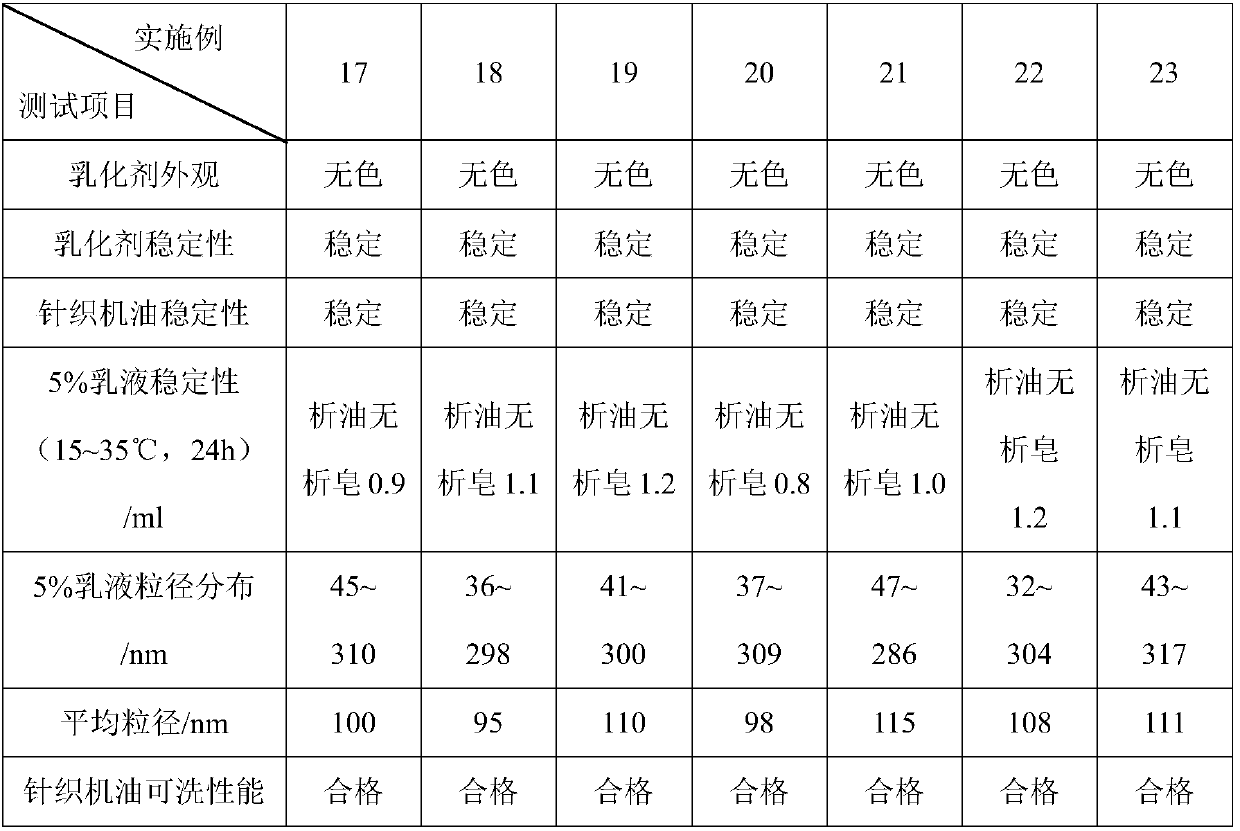

Examples

Embodiment 1

[0021] Raw material components: oleic acid monoglyceride 40g, C 12 Acid polyoxyethylene (3) ester 360g, C 12~14 Alcohol polyoxyethylene (9) ether 90g, C 12~14 Alcohol polyoxyethylene (3) ether sodium sulfate 10g and nonylphenol polyoxyethylene (5) ether 30g.

[0022] Preparation method: Put the above-mentioned raw materials into the blending kettle, start heating and stirring, wait until the temperature rises to 60°C, keep warm for about 30 minutes, observe the appearance of the system, after it is clear and transparent, filter at 30°C to remove possible mechanical impurities, Samples were then taken for emulsifier stability evaluation.

[0023] Preparation of knitting machine oil: compound the above-mentioned emulsifier and mineral oil for knitting machine oil, take 100g of the above-mentioned emulsifier, add 1000g of mineral oil 70N, 0.5g of benzotriazole, 0.5g of 2,6-di-tert-butyl-4- For methyl phenol, stir at 60°C for 30 minutes. After the system is clear and transparen...

Embodiment 2

[0030] The basic steps are the same as in Example 1, the difference is that C 12 ~ 14 Alcohol polyoxyethylene (3) ether instead of C 12 Acid polyoxyethylene (3) ester.

Embodiment 3

[0032] The basic steps are the same as in Example 2, except that nonylphenol polyoxyethylene (4) ether is used instead of nonylphenol polyoxyethylene (5) ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com