Bottom ring material DPR-D5 of piston rings of marine diesel engine and casting method thereof

A marine diesel engine, DPR-D5 technology, applied in the direction of piston rings, mechanical equipment, engine components, etc., can solve the problems of long order cycle and high cost, and achieve high bending strength, moderate hardness, good wear resistance and corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The casting method of the piston ring bottom ring of marine diesel engine comprises the following steps:

[0029] 1. Ingredients according to the following mass percentage: C: 3.0%, Si: 1.4%, Mn: 0.84%, Cr: 0.1%, Mo: 0.49%, Cu: 0.99%, Ti: ≤0.05%, P: 0.1%, S ≤0.05%, Mg: ≤0.005%, the rest is Fe and unavoidable impurities;

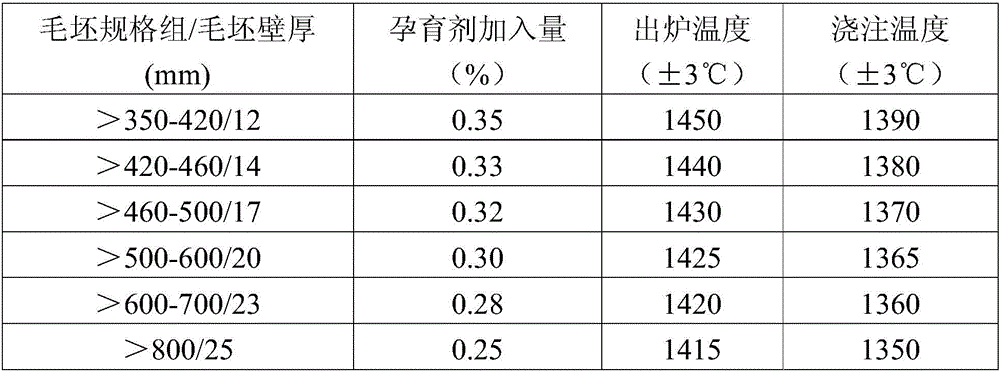

[0030] 2. Melting: Melt the ingredients in step 1 into molten iron with a frequency conversion induction furnace. The casting is a cylindrical blank with a diameter of 350mm and a wall thickness of 12mm. Adjust the furnace temperature to 1450°C and add 0.35% inoculant.

[0031] The matrix structure of cast alloy cast iron DPR-D5 is pearlite, a small amount of ferrite and hard phase (cementite + phosphorus eutectic), and the force elastic modulus E reaches 112kN / mm 2 , Brinell hardness is HB219, bending strength Rb=560N / mm 2 .

Embodiment 2

[0033] The casting method of the piston ring bottom ring of marine diesel engine comprises the following steps:

[0034] 1. Ingredients according to the following mass percentage: C: 3.2%, Si: 1.4%, Mn: 0.84%, Cr: 0.1%, Mo: 0.49%, Cu: 0.99%, Ti: ≤0.05%, P: 0.1%, S ≤0.05%, Mg: ≤0.005%, the rest is Fe and unavoidable impurities;

[0035] 2. Melting: Melt the ingredients in step 1 into molten iron with a frequency conversion induction furnace. The casting is a cylindrical blank with a diameter of 700mm and a wall thickness of 23mm. Adjust the furnace temperature to 1420°C and add 0.28% inoculant.

[0036] The matrix structure of cast alloy cast iron DPR-D5 is pearlite, a small amount of ferrite and hard phase (cementite + phosphorus eutectic), and the force elastic modulus E reaches 120kN / mm 2 , Brinell hardness is HB226, bending strength Rb=600N / mm 2 .

Embodiment 3

[0038] The casting method of the piston ring bottom ring of marine diesel engine comprises the following steps:

[0039] Carry out smelting when the air temperature is -15 DEG C according to the step of Embodiment 2, pouring temperature is 1363 DEG C, all the other are the same as Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com