Electrocatalyst for sunlight-drive water electrolysis oxygen evolution reaction and preparation method of electrocatalyst

A technology for oxygen evolution reaction and electrocatalyst, which is applied in the field of electrocatalyst for sunlight-driven electrolysis of water for oxygen evolution reaction and its preparation field, can solve the problems of high cost, limited application scale, etc., achieves simple production process principle, and improves energy use efficiency , the effect of high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mix 5 grams of melamine into 250 milliliters of milk, stir with an electromagnetic stirrer, and gradually add NH with a mass concentration of 25% 3 ·H 2 O to the mixed solution, monitored with pH test paper until the pH value is close to 10 and presents a weak base state, creating conditions for the hydrolysis reaction of tetraethyl orthosilicate (TEOS);

[0022] (2) Add 15 milliliters of TEOS to the above-mentioned homogeneously mixed solution, and then continue to stir for 1 hour, and TEOS is hydrolyzed to generate silicon dioxide (SiO 2 )structure;

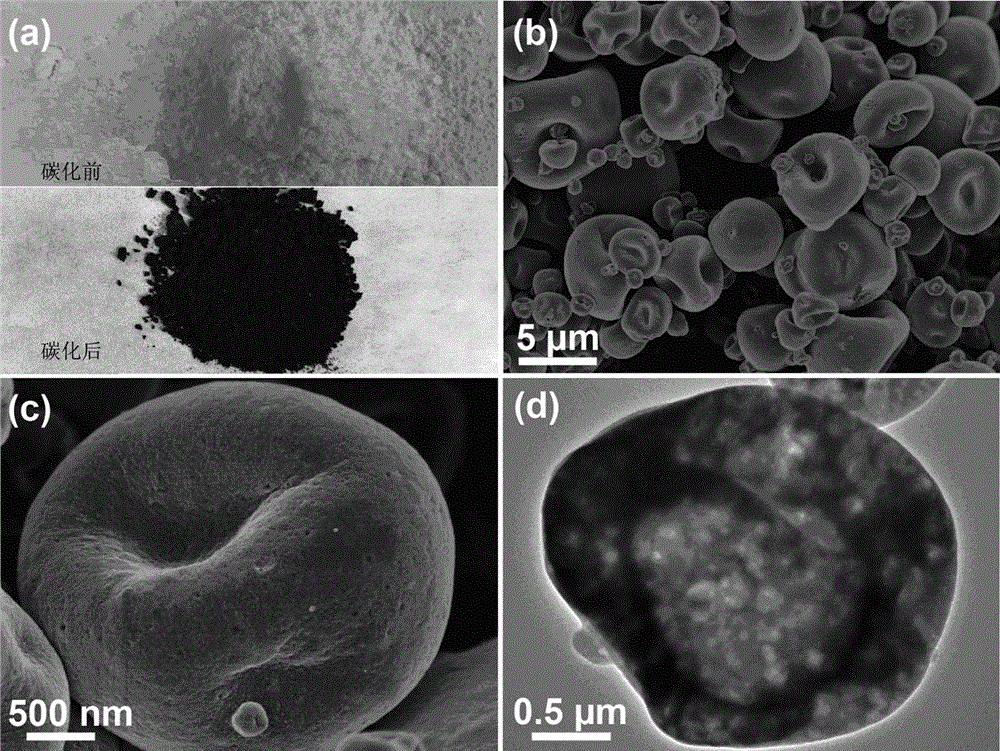

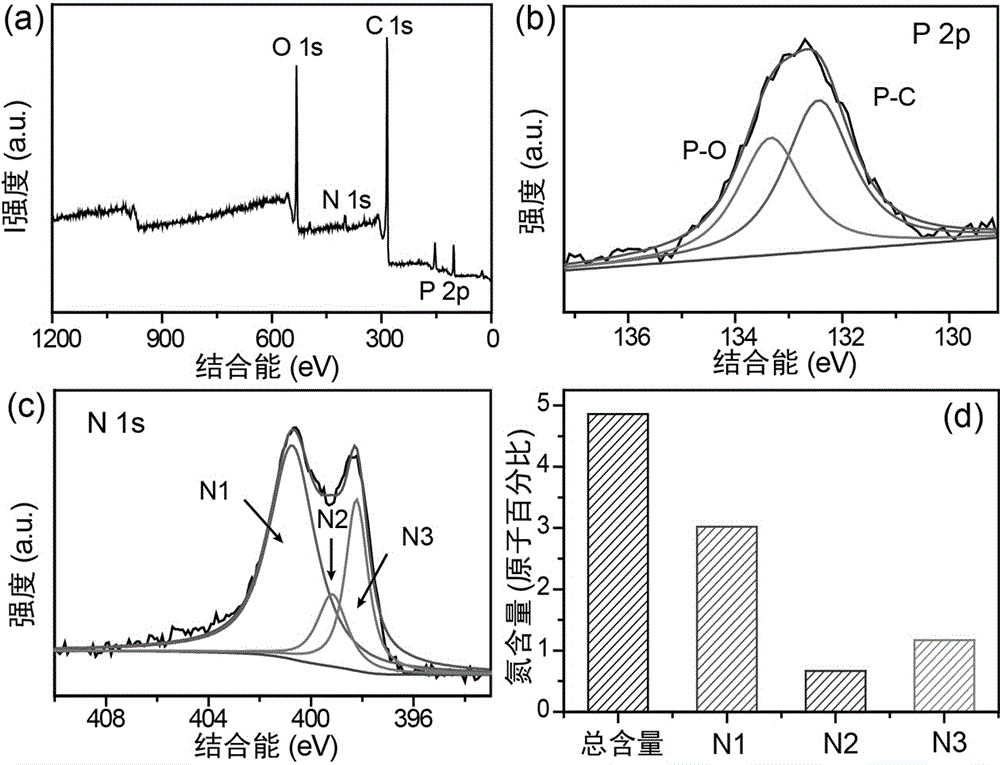

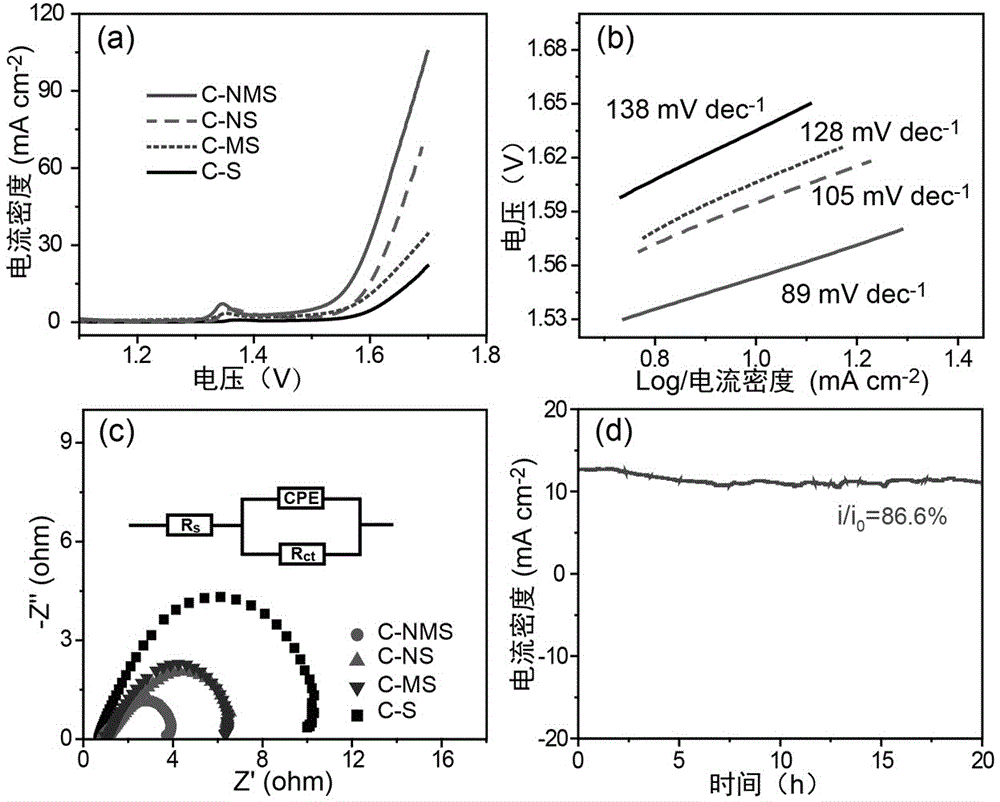

[0023] (3) The prepared milk / SiO 2 The solution is pumped into the heating chamber of the spray dryer, sprayed and dried at 180°C to form a white powder; the powder is collected, placed in a ceramic dish and placed in a high-temperature tube furnace, filled with argon (Ar) for calcination— —Rise 3°C per minute until 800°C, continue calcination at 800°C for 2 hours, the original white powder is carbonized into blac...

Embodiment 2

[0034] Mix 10 g of melamine into 250 ml of milk, stir with an electromagnetic stirrer, and gradually add 10 mL of NH with a mass concentration of 25%. 3 ·H 2 O into the mixed solution to create conditions for the hydrolysis reaction of tetraethyl orthosilicate (TEOS); add 10 milliliters of TEOS to the above-mentioned uniform mixed solution, and continue stirring for 1.5 hours, and TEOS is hydrolyzed to generate silicon dioxide (SiO 2 ) structure; the prepared milk / SiO 2The solution is pumped into the heating chamber of the spray dryer, sprayed and dried at 175°C to form a white powder; the powder is collected, placed in a ceramic dish and placed in a high-temperature tube furnace, filled with argon (Ar) for calcination— —Rise 2°C per minute until 900°C, continue calcination at 900°C for 3 hours, the original white powder is carbonized into black powder, milk and melamine are converted into nitrogen-containing carbon structure by heating, and interlaced with nanoporous silica ...

Embodiment 3

[0036] Add 30 g of soybean powder to 250 ml of deionized water, after fully dissolving, remove insoluble impurities by filtration, then mix in 15 g of melamine, stir with an electromagnetic stirrer, and gradually add NH with a mass concentration of 25%. 3 ·H 2 O to the mixed solution, monitor with pH test paper until the pH value is close to 10, showing a weak base state, and create conditions for the hydrolysis reaction of tetraethyl orthosilicate (TEOS); add 15 ml of TEOS to the above-mentioned uniform mixed solution, and continue to stir for 1 hour , TEOS is hydrolyzed to form silica (SiO 2 ) structure; the prepared milk / SiO 2 The solution is pumped into the heating chamber of the spray dryer, sprayed and dried at 180°C to form a white powder; the powder is collected, placed in a ceramic dish and placed in a high-temperature tube furnace, filled with argon (Ar) for calcination— —Increase 3°C per minute until 800°C, continue calcination at 800°C for 2 hours, the original y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com