A kind of anti-ultraviolet aromatic high-performance fiber based on poss grafting and its modification method

A high-performance fiber, anti-ultraviolet technology, applied in the direction of light-resistant fiber, fiber type, fiber treatment, etc., can solve the problems of poor anti-ultraviolet performance and water washing resistance, achieve small physical and mechanical properties of fibers, improve strength retention rate, and solve the Poor washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

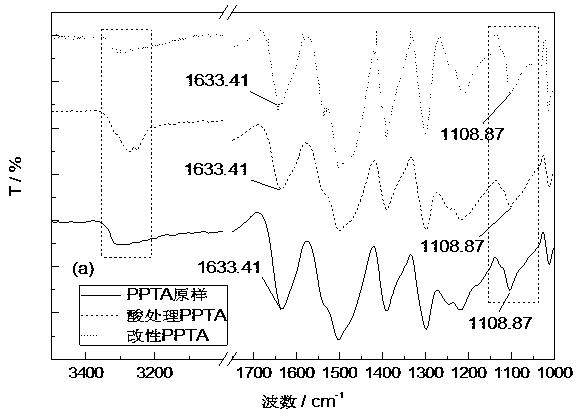

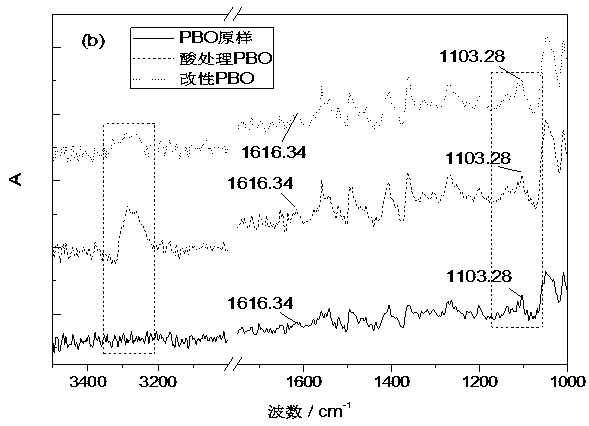

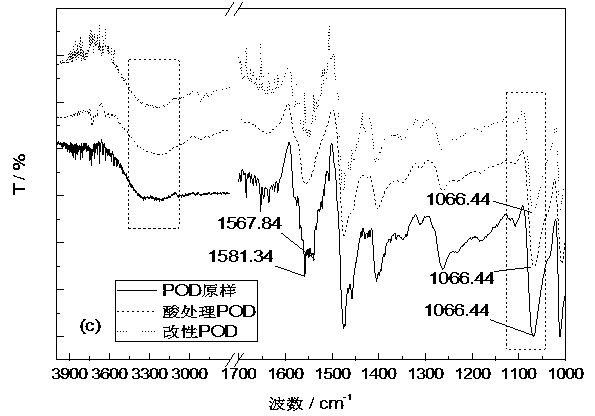

[0039] In parts by weight, soak 100 parts of PPTA fiber in 50wt% sulfuric acid solution at 50°C for 10 hours, rinse it in tap water immediately after taking it out, and then soak it in 5g / L sodium bicarbonate solution for 5 minutes to neutralize the residual acid After taking out the sample, wash it twice in cold distilled water and hot distilled water respectively, and finally dry it naturally in a light-proof and ventilated environment. Weigh 10 parts of acid-pretreated fibers and place them in a round bottom flask, add 10 parts of dichloromethane and 20 parts of thionyl chloride, and heat to reflux for 8 hours. After the reaction is over, take out the fiber, filter it dry, and then use 100 parts of dichloromethane to repeatedly stir and wash it, take it out and hang it in a dark and ventilated place to dry. Put 10 parts of aminopropyl POSS into a round bottom flask, add 5 parts of dichloromethane and 25 parts of saturated aqueous sodium chloride. Slowly add 20 g / L NaOH sol...

Embodiment 2

[0070] In parts by weight, soak 100 parts of PPTA fiber in 70% polyphosphoric acid / sulfuric acid (volume ratio 1:1) mixed solution at 45°C for 6 hours, rinse it in tap water immediately after taking it out, and then put 1g / L bicarbonate Soak in sodium / sodium carbonate (volume ratio 1:1) mixed solution for 30 minutes to neutralize the residual acid, take out the sample, wash it twice in cold distilled water and hot distilled water respectively, and finally dry it naturally in a light-proof and ventilated environment . Weigh 5 parts of acid-pretreated fibers and place them in a round-bottomed flask, add 40 parts of dichloromethane and 1 part of thionyl chloride, and heat to reflux for 10 hours. After the reaction is over, take out the fiber, filter it dry, and then use 40 parts of dichloromethane to stir and wash it repeatedly, take it out and hang it in a dark and ventilated place to dry. Put 8 parts of aminomethyl POSS / aminoethyl POSS (molar ratio 1:1) into a round bottom fla...

Embodiment 3

[0074] In parts by weight, soak 100 parts of PPTA fiber in 40% methanesulfonic acid solution at 40°C for 2 hours, rinse it in tap water immediately after taking it out, and then soak it in 10g / L sodium hydroxide solution for 15 minutes to neutralize the residual After taking out the sample, wash it twice in cold distilled water and hot distilled water respectively, and finally dry it naturally in a light-proof and ventilated environment. Weigh 8 parts of the acid-pretreated fibers and place them in a round-bottomed flask, add 50 parts of methylene chloride and 30 parts of thionyl chloride, and heat to reflux for 1 hour. After the reaction is over, take out the fiber, filter it dry, and then use 60 parts of dichloromethane to repeatedly stir and wash it, take it out and hang it in a dark and ventilated place to dry. Put 1 part of aminoethyl POSS into a round bottom flask, add 50 parts of dichloromethane and 50 parts of saturated aqueous sodium chloride. Slowly add 5 g / L NaOH s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com