Novel amorphous magnetic powder core and preparation method thereof

A magnetic powder core and amorphous technology, applied in the field of new amorphous magnetic powder core and its preparation, can solve the problems of unbalanced efficiency, increased reactive power consumption, damage to switching devices, etc., to achieve reduced efficiency, increased reactive power consumption, Effect of Reducing Switching Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A novel amorphous magnetic powder core of the present invention is made by mixing amorphous alloy powder particles with metal soft tape materials, and its preparation method steps are as follows:

[0023] 1) Pretreatment of amorphous alloy powder particles, first dehumidify the amorphous alloy powder particles with a particle size of -100 to -500 mesh, and mix the dehumidified amorphous alloy powder particles with an insulating coating agent to control the insulating coating The amount of the coating agent added is 0.5%-8% of the mass of the amorphous alloy powder particles, the mixing treatment temperature is controlled at 20-130°C, and the mixing treatment time is 5-80 minutes, which is the pretreatment of the amorphous alloy powder particles;

[0024] 2) Heat treatment of flexible metal tapes, immersing a metal strip with a thickness of 15-500 microns in a sodium silicate or potassium silicate solution with a mass concentration of 1-20Wt%, and then at a temperature of...

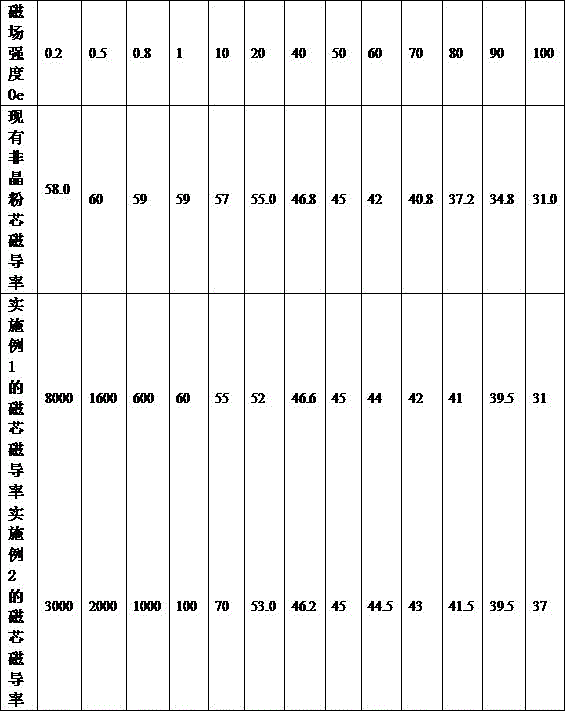

Embodiment 1

[0034]1) Soak 150-mesh amorphous alloy powder with a weight of 23.5 grams in a dehumidifier for 10 minutes for dehumidification treatment. The dehumidifier is a mixture of 1% Wt phosphoric acid + 1 Wt % sodium silicate solution in mass concentration liquid, and then baked at 100°C for 20 minutes; 2) Iron-based nanocrystals with a thickness of 25 microns, national standard 1k107, metal winding cores, namely metal strips, with a size of OD23mm*ID20mm*HT6.5mm, Soak in sodium silicate diluted 30 times for 5 minutes, and then bake at 200°C for 50 minutes; 3) Put 12g of treated amorphous alloy powder into the cavity of OD26.9mm*ID14.7mm*HT11.2mm middle. 4) Put the metal winding magnetic core prepared in the second step into the mold cavity. 5) Then put the remaining 11.5 amorphous alloy powder into it. 6) The pressure reaches 21T / cm 2 Keep it for 10 seconds, and eject the mold; 7) Heat the pressure-molded magnetic core to 200°C under the condition of vacuum degree of 0.08Pa, and ...

Embodiment 2

[0035] Embodiment 2 The specific embodiment of this implementation is the same as Embodiment 1 and the above description except for the following description.

[0036] 1) Put 250-mesh amorphous alloy powder with a weight of 40 grams into a desiccant solution consisting of 0.8 g of tetraethyl orthosilicate and 0.8 g of zinc stearate, that is, the desiccant is composed of 0.8 g of orthosilicon A mixed solution of ethyl acetate and 0.8 g of zinc stearate. Soak and heat to 80°C for 20 minutes; 2) Wind the iron-nickel alloy strip (national standard 1j79) with a thickness of 50 microns around the magnetic core (the size is OD30mm*ID24mm*HT10mm), and dilute it 10 times with The final sodium silicate solution, that is, a sodium silicate solution with a mass concentration of 1%, was soaked for 5 minutes, and then baked at 300°C for 30 minutes. 3) Put 20g of treated amorphous alloy powder into the mold cavity of OD40mm*ID15mm*HT14mm. 4) Put the metal winding magnetic core prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com