Preparation method for porous carbon material electrode for counter electrode of dye-sensitized solar cell

A technology of solar cells and porous carbon materials, applied in the field of dye-sensitized solar cells, can solve the problems of high resistance and low photoelectric conversion efficiency, and achieve the effects of simple process, optimized photoelectric performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

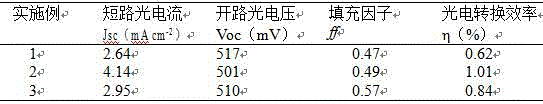

Embodiment 1

[0031] A kind of porous carbon material is used as the preparation method of the dye-sensitized solar cell of opposite electrode, comprises the following steps:

[0032] (1) Put the conductive glass (FTO) on the slide with a glass knife, then ultrasonically clean it with distilled water, after drying, ultrasonically clean it in acetone and ethanol solutions for 15 minutes, and soak the conductive glass in isopropanol solution for more than 24 hours for later use .

[0033] (2) Preparation of porous carbon counter electrode: 0.3 g of ZIF-8 powder was ground in a mortar for 3 hours, then 3 mL of n-butanol was added, and 2 mL of ZIF-8 colloid was coated by screen printing Put it on the FTO conductive glass, dry it at room temperature, put it in a tube furnace, and carbonize it under the protection of nitrogen at 400°C for 3 hours. After the temperature drops to room temperature, take it out and use it as the counter electrode of porous carbon material; carbonization It needs to ...

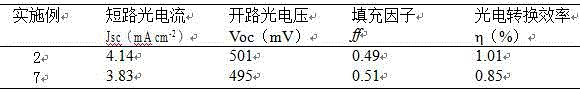

Embodiment 2

[0039] A kind of porous carbon material is as the preparation method of the dye-sensitized solar cell of counter electrode, and its step is identical with embodiment 1, and difference is:

[0040] Take a piece of soaked conductive glass and blow dry. Put 0.3 g of the synthesized ZIF-8 powder in a mortar, add 3 mL of n-butanol, and grind it in the mortar for 3 hours in order to disperse the aggregated ZIF-8 powder particles well. Then, 2 mL of ZIF-8 colloid was coated on the FTO conductive glass by screen printing, dried and carbonized in a tube furnace at 400 °C under nitrogen protection for 4 hours to obtain a porous carbon material counter electrode.

Embodiment 3

[0042] A kind of porous carbon material is as the preparation method of the dye-sensitized solar cell of opposite electrode, and its steps are identical with embodiment 1,2, and difference is:

[0043] Take a piece of soaked conductive glass and blow dry. Put 0.3 g of the synthesized ZIF-8 powder in a mortar, add 3 mL of n-butanol, and grind it in the mortar for 3 hours in order to disperse the aggregated ZIF-8 powder particles well. Then, 2 mL of ZIF-8 colloid was coated on the FTO conductive glass by screen printing, dried and carbonized in a tube furnace at 400 °C under nitrogen protection for 5 hours to obtain a porous carbon material counter electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com