Hollow microsphere molecular sieve, preparation method thereof and application thereof to arene preparation through methyl alcohol

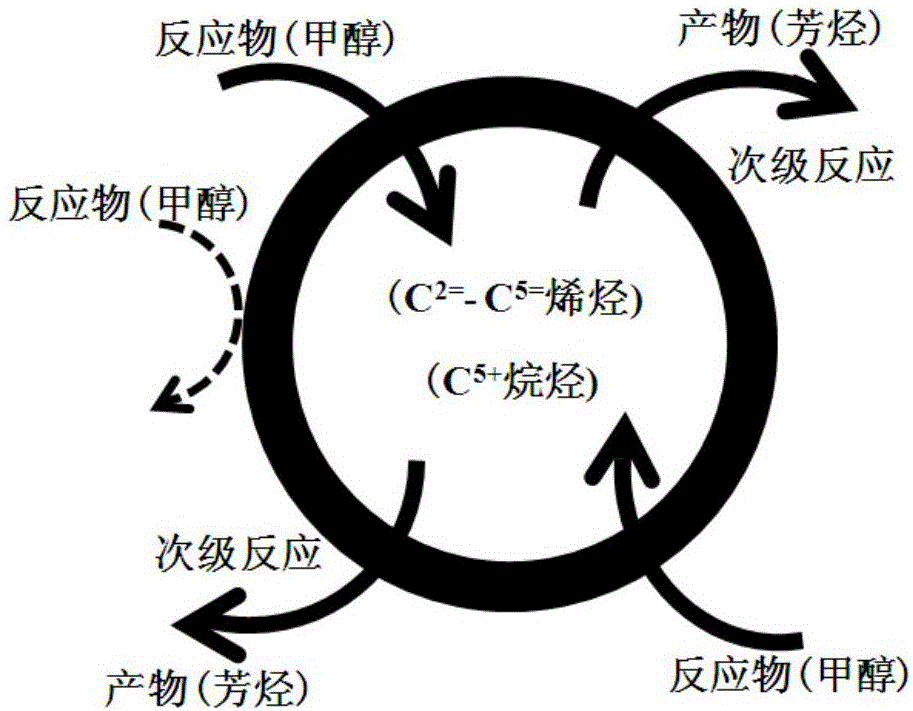

A molecular sieve and hollow technology, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of high selectivity and long life of aromatics, so as to facilitate diffusion, increase life, and improve selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

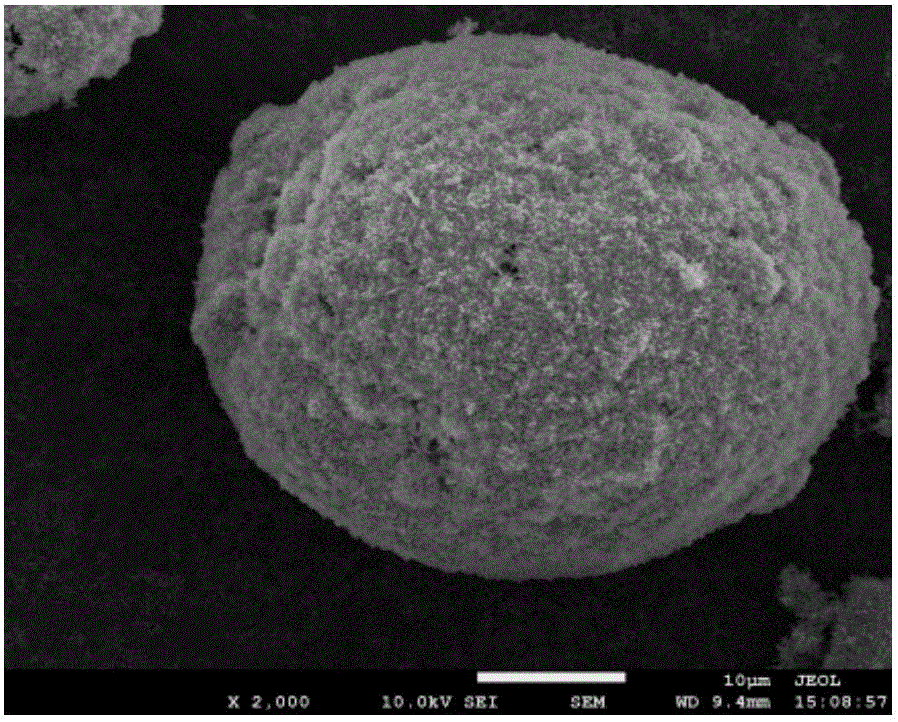

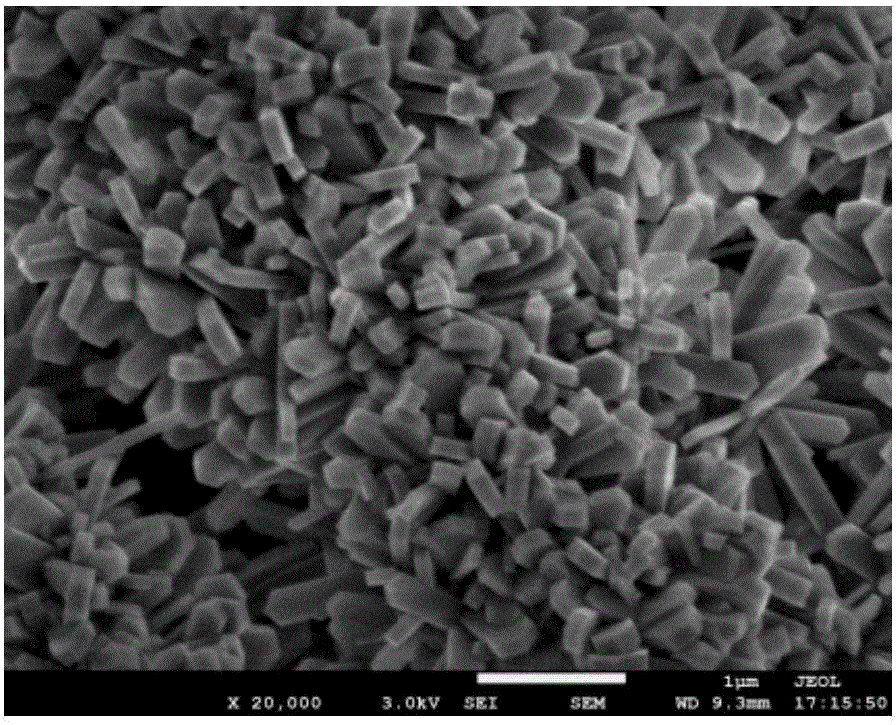

[0043] The present invention also provides a method for preparing the hollow microsphere molecular sieve described in the above technical solution, comprising the following steps:

[0044] (1) Mix the silicon source, aluminum source, n-butylamine, EDTA chelating agent and water, adjust the pH value to 8-10, and stir to obtain the sol;

[0045] (2) hydrothermal crystallization of the sol obtained in the step (1) to obtain the former powder of molecular sieve;

[0046] (3) Roasting the molecular sieve former powder that described step (2) obtains, obtains modified molecular sieve;

[0047] (4) performing ion exchange on the modified molecular sieve obtained in the step (3) to obtain an ammonium molecular sieve;

[0048](5) Calcining the ammonium molecular sieve obtained in the step (4) to obtain a hollow microsphere molecular sieve.

[0049] The invention mixes silicon source, aluminum source, n-butylamine, EDTA chelating agent and water, adjusts pH value to 8-10, and stirs to...

Embodiment 1

[0069] According to the molar ratio Si:Al:n-butylamine:EDTA-Na 2 : water=1:0.028:0.15:0.08:31 ratio, sodium metaaluminate is added to water, stir until clear; add n-butylamine and EDTA-Na 2 , and finally add silica sol (JN-40, 40.5wt%of SiO 2 , Qingdao Haiyang Chem.Co.).

[0070] The pH of the synthesis system was maintained at 8.5 with 5 mol / L NaOH solution, and stirred at a rate of 500 r / min for 0.5 h to form a uniform sol.

[0071] The above-mentioned sol was transferred into a synthesis kettle lined with polytetrafluoroethylene, and rotated and dynamically crystallized at a speed of 20 r / min for 38 hours in a homogeneous reactor at 170°C.

[0072] The crystallized product was fully washed, centrifuged and dried at 105°C for 12 hours to obtain the molecular sieve powder.

[0073] The original powder was calcined at 450°C for 24 hours in the air to obtain the modified molecular sieve.

[0074] The modified molecular sieve was mixed with 0.8mol / L ammonium nitrate solution...

Embodiment 2

[0078] According to the molar ratio Si:Al:n-butylamine:EDTA-Na 2 : water=1:0.02:0.15:0.08:31 ratio, sodium metaaluminate is added to water, stir until clear; add n-butylamine and EDTA-Na 2 , and finally add silica sol (JN-40, 40.5wt%of SiO 2 , Qingdao Haiyang Chem.Co.).

[0079] Use NaOH solution to maintain the pH of the synthesis system = 8.5 to form a uniform sol.

[0080] The above-mentioned sol was transferred into a synthesis kettle lined with polytetrafluoroethylene, and rotated and dynamically crystallized at a speed of 20 r / min for 38 hours in a homogeneous reactor at 170°C.

[0081] The crystallized product was fully washed, centrifuged and dried at 105°C for 12 hours to obtain the molecular sieve powder.

[0082] The original powder was calcined at 450°C for 24 hours in the air to obtain the modified molecular sieve.

[0083] Mix the modified molecular sieve with 1.2mol / L ammonium nitrate solution at 90°C, perform ion exchange twice to obtain ammonium molecular si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com