Dye-sensitized solar cell counter electrode and its preparation method and application

An electrode and base electrode technology, applied in the field of dye-sensitized solar cells, can solve problems such as uncontrollable internal pore structure and affect electrochemical performance, and achieve the effects of improving electrocatalytic activity and conductivity, low production cost, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

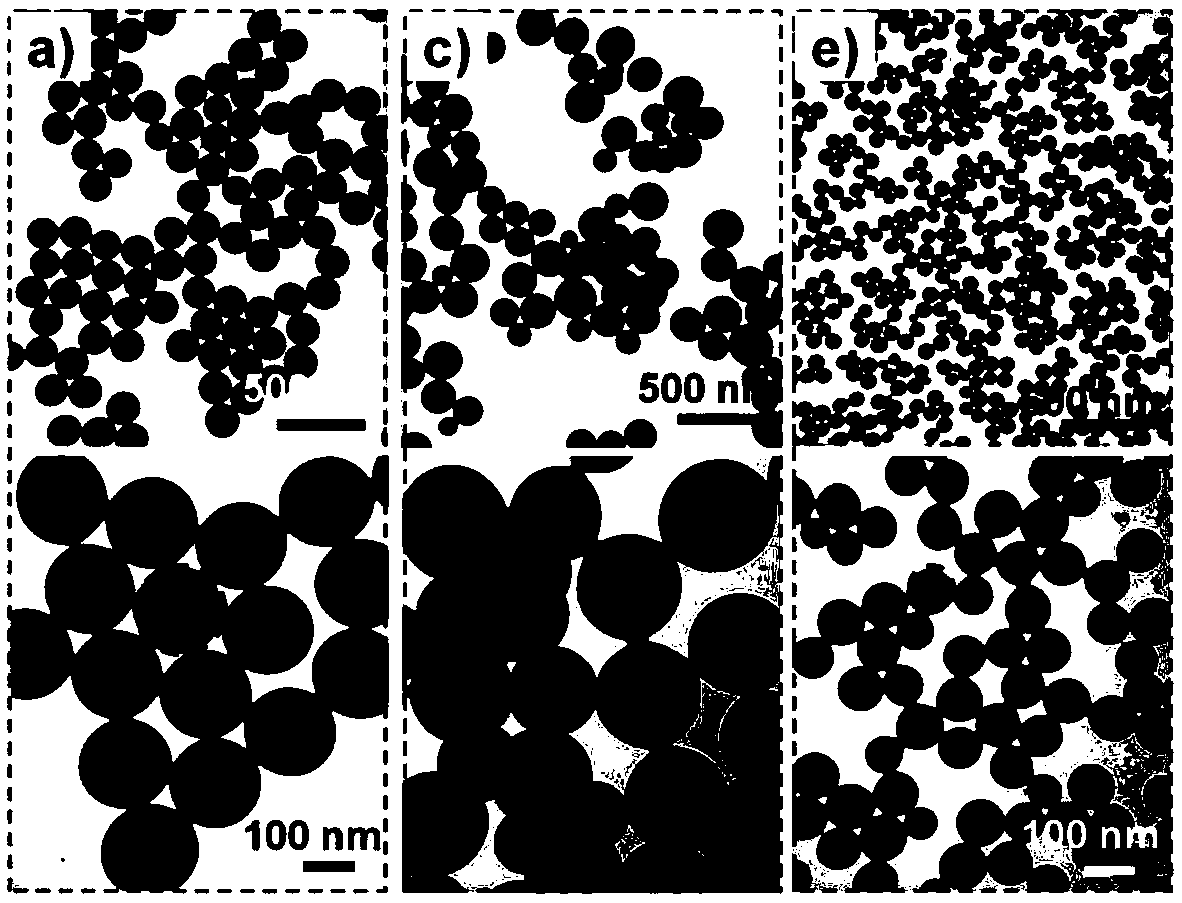

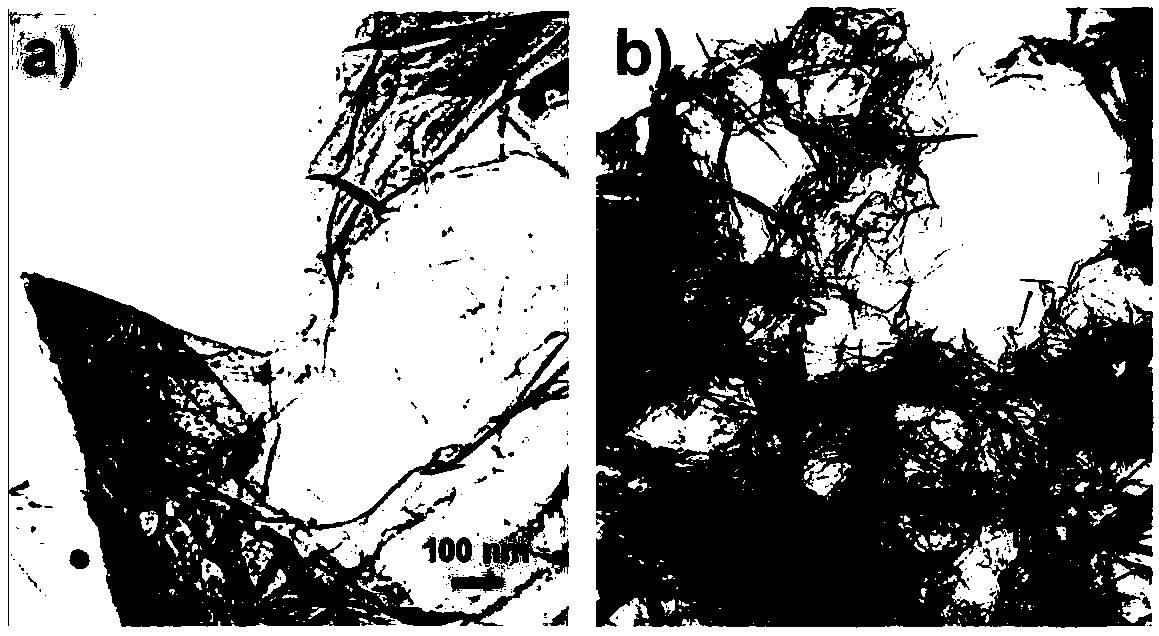

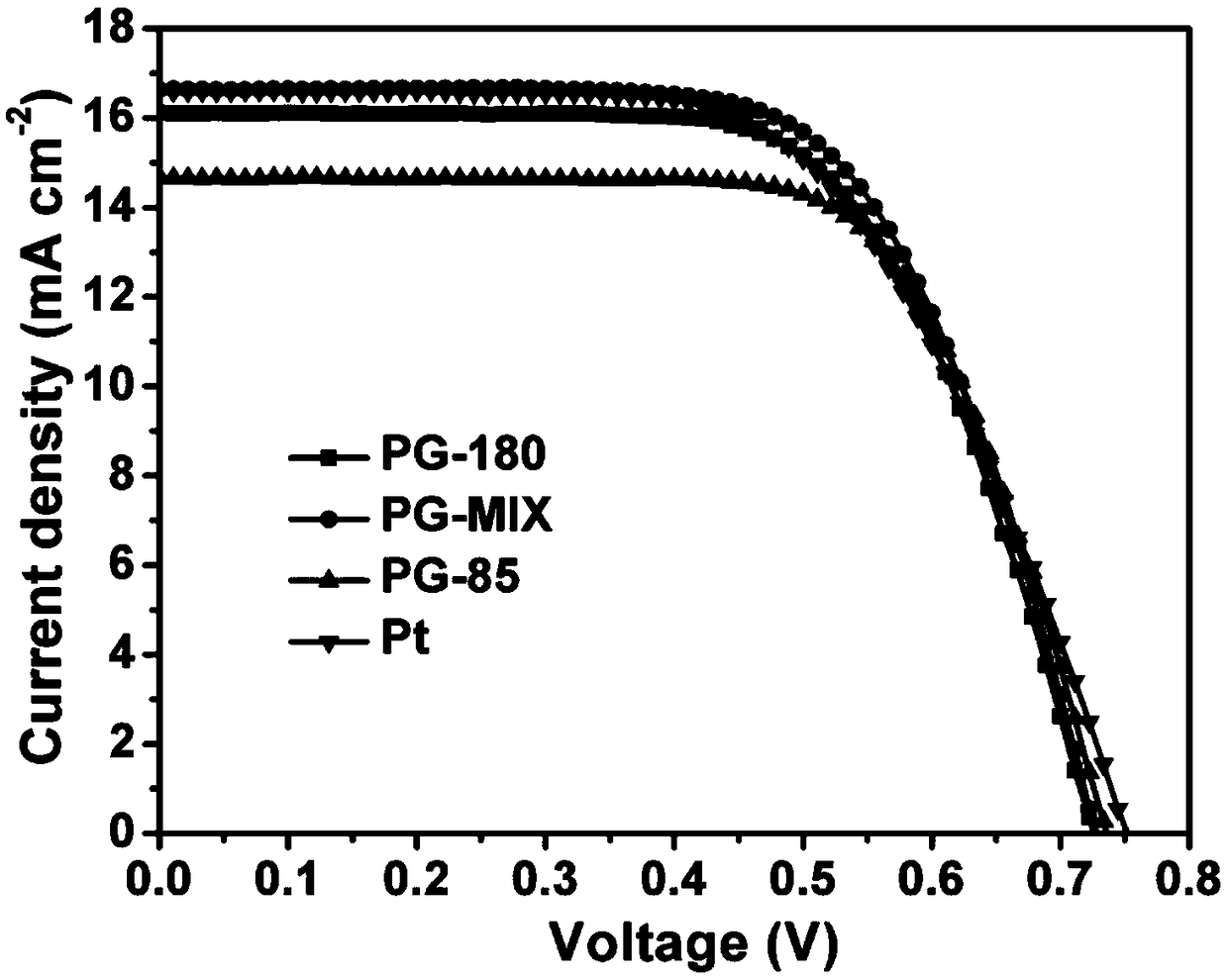

[0067] Take 300ml of secondary water and add it into a 1L flask, keep the temperature at 70°C and the speed at 400r / min. Add 0.1g sodium styrene sulfonate, 55ml styrene, and react for 20min. Add 1 g of potassium persulfate, 150 ml of secondary water, and polymerize for 18 hours under a nitrogen-protected atmosphere to obtain a suspension of PS spheres with a diameter of 180 nm. The PS sphere suspension was centrifuged and washed three times with secondary water and ethanol respectively, and the finally obtained pure PS sphere was diluted with water to 30 mg / mL. Take 4ml of the above PS sphere suspension and add it to 25ml of GO dispersion with a concentration of 2.5mg / ml, and sonicate for 30min. Add 0.8 g of thiourea, continue to sonicate for 10 min, add 3 drops of ammonia water dropwise, and adjust the pH to 10. The above reaction solution was transferred to a 50mL reactor and reacted at 160°C for 20h. The obtained graphene gel was freeze-dried at -45°C for 48 hours to obt...

Embodiment 2

[0070] Take 350ml of secondary water and add it into a 1L flask, keep the temperature at 70°C and the rotation speed at 400r / min. Add 0.05g sodium styrene sulfonate, 55ml styrene, and react for 30min. Add 1 g of potassium persulfate, 100 ml of secondary water, and polymerize for 20 h under a nitrogen-protected atmosphere to obtain a mixed suspension of PS spheres with a diameter of 130 nm / 170 nm / 230 nm. The PS sphere suspension was centrifuged and washed three times with secondary water and ethanol respectively, and the finally obtained pure PS sphere was diluted with water to 30 mg / mL. Take 4ml of the above PS sphere suspension and add it to 25ml of GO dispersion with a concentration of 2.5mg / ml, and sonicate for 30min. Add 0.8 g of thiourea, continue to sonicate for 10 min, add 3 drops of ammonia water dropwise, and adjust the pH to 10. The above reaction solution was transferred to a 50mL reactor and reacted at 160°C for 15h. The obtained graphene gel was freeze-dried at...

Embodiment 3

[0074] Take 350ml of secondary water and add it into a 1L flask, keep the temperature at 80°C and the rotation speed at 350r / min. Add 0.75g sodium styrene sulfonate, 50ml styrene, and react for 30min. Add 1 g of potassium persulfate, 100 ml of secondary water, and polymerize for 18 hours under a nitrogen-protected atmosphere to obtain a suspension of PS spheres with a diameter of 85 nm. The PS sphere suspension was centrifuged and washed three times with secondary water and ethanol respectively, and the finally obtained pure PS sphere was diluted with water to 30 mg / mL. Take 2ml of the above PS sphere suspension and add it to 25ml of GO dispersion with a concentration of 2.5mg / ml, and sonicate for 30min. Add 1 g of thiourea, continue to sonicate for 5 minutes, add 3 drops of ammonia water dropwise, and adjust the pH to 10. The above reaction solution was transferred to a 50mL reactor and reacted at 160°C for 15h.

[0075] The drying and carbonization steps are the same as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com