Biodegradable material prepared from edible fungi residues and preparation method of biodegradable material

A technology for biodegradable materials and edible fungi, applied in the field of waste and agricultural and sideline product resource utilization and environmental protection, can solve problems such as environmental pollution, reduce white pollution, achieve large-scale industrial production, and reduce three wastes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A biodegradable material, extruded from the following raw materials in weight percentage: Ganoderma lucidum residue 82%, sugarcane fiber 10%, polyvinyl alcohol 3%, modified starch 2%, barium stearate 1%, magnesium stearate 2%.

[0038] The preparation method of the biodegradable material is as follows:

[0039] (1) Disperse or pulverize the freshly collected ganoderma lucidum residue, and control the moisture content to 50%.

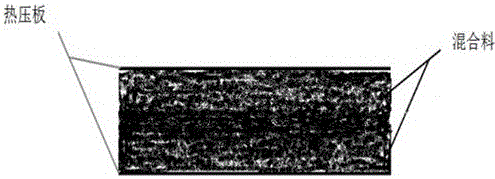

[0040](2) Mix sugarcane fiber, polyvinyl alcohol, modified starch, barium stearate and magnesium stearate into the Ganoderma lucidum slag prepared in step (1), mix evenly, then place the mixture in a mold, and finally pass The hot pressing machine is at a hot pressing temperature of 160° C. and a hot pressing pressure of 2.0 MPa, and after continuous extrusion for 3 minutes, the material is formed.

[0041] (3) The molded material obtained in step (2) is dried in an oven at 90°C for more than 4 hours, and the mycelium is inactivated at the same ...

Embodiment 2

[0043] The invention discloses a biodegradable material of edible fungus residue, which is extruded from raw materials with the following weight percentages: 85% of Flammulina velutipes residue and 15% of corn stalk fiber.

[0044] The preparation method of the biodegradable material is as follows:

[0045] (1) Disperse or pulverize the freshly collected Flammulina velutipes slag, and control the moisture content to 60%.

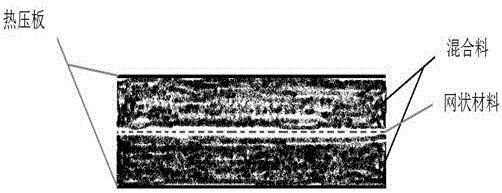

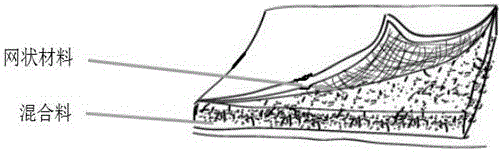

[0046] (2) Mix corn stalks into the enoki mushroom residue prepared in step (1), mix well, then put the mixture in the mold, add a sieve in the middle of the mixture, fill the mold with the mixture, and finally heat press The machine is at a hot pressing temperature of 180°C and a hot pressing pressure of 2.5 MPa, and after continuous extrusion for 6 minutes, the material is formed.

[0047] (3) The molded material obtained in step (2) was dried in an oven at 90°C for more than 4 hours, and the hyphae were inactivated at the same time, and then cut to obtai...

Embodiment 3

[0049] A biodegradable material of edible fungus residue is extruded from the following raw materials in weight percentage: 75% of Pleurotus eryngii mushroom residue, 15% of sawdust fiber, 5% of polyvinyl alcohol, and 5% of phenolic resin.

[0050] The preparation method of the degradable material is as follows:

[0051] (1) Disperse or pulverize the Pleurotus eryngii mushroom dregs after freshly collected fruit bodies, and control the moisture content to 60%.

[0052] (2) Mix sawdust fiber, polyvinyl alcohol and phenolic resin into the pleurotus eryngii slag prepared in step (1), mix evenly, then place the mixture in a mold, add a wire mesh in the middle of the mixture, add the mixture The mold is full, and finally the material is shaped after being continuously extruded by a hot press machine at a hot pressing temperature of 200°C and a hot pressing pressure of 3.0 MPa for 8 minutes.

[0053] (3) The molded material obtained in step (2) is dried in an oven at 95°C for more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com