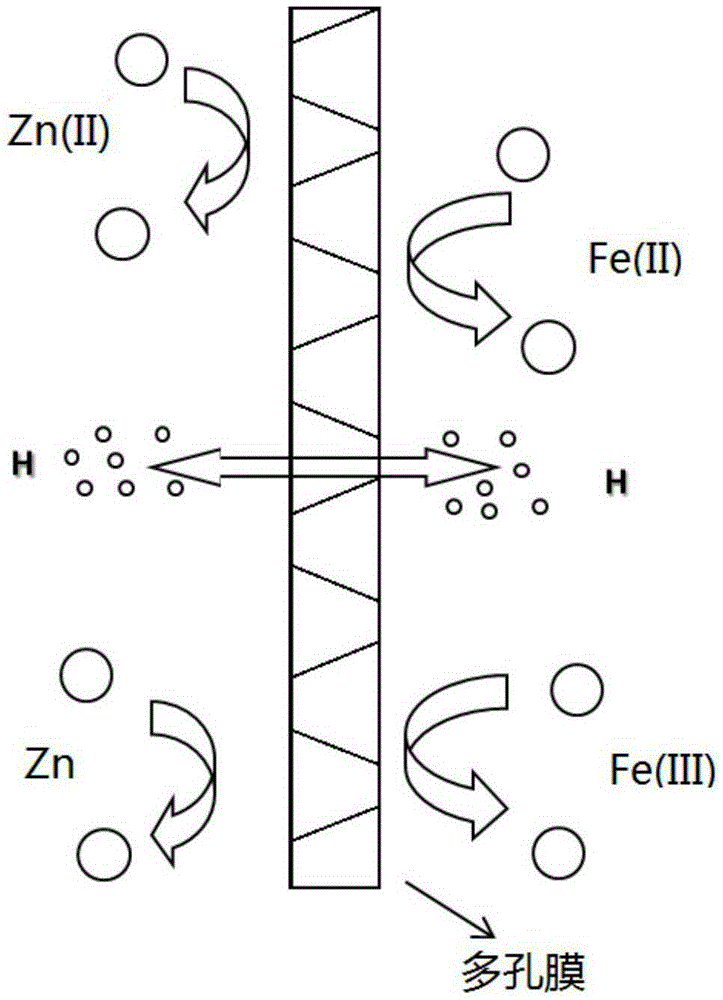

Application of composite membrane in neutral system zinc-iron flow battery

A technology for flow batteries and composite membranes, applied in neutral system zinc-iron flow batteries, in the field of composite membranes for neutral system zinc-iron flow batteries, can solve problems such as the difficulty of reducing pore size, and achieve the expansion of types and the effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

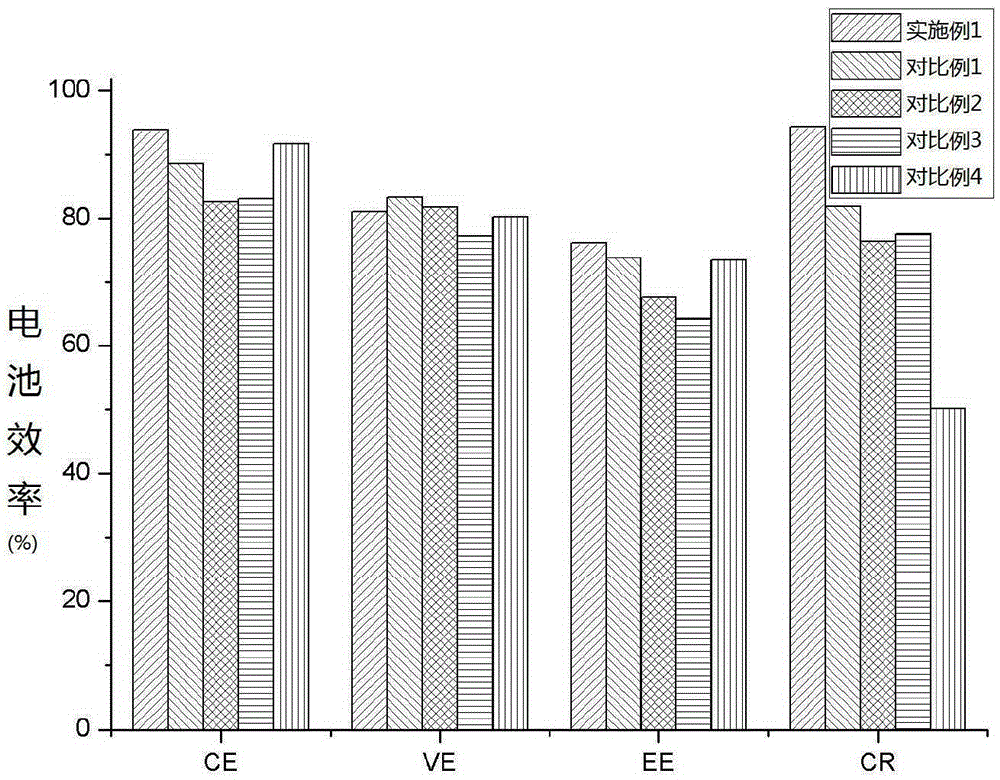

Examples

Embodiment 1

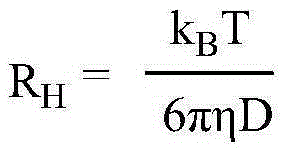

[0037] Dissolve 7.5 g of polyacrylonitrile in 30 ml of DMSO and 10 ml of THF, stir for 5 hours, spread the resulting polymer solution on a glass plate with a thickness of 250 μm, and then quickly immerse it in 5 L of water to solidify to form a porous diaphragm.

[0038] The prepared porous diaphragm was treated in 10 wt.% sodium hydroxide aqueous solution for 55 minutes, and the treatment temperature was 55°C. Then the membrane was cleaned with deionized water, soaked in ethanol for 2 hours, and the water in it was replaced.

[0039] A DMAC solution of Nafion resin with a concentration of 2wt.% was prepared and coated on the surface of the porous membrane with a spin coater. Rotate at a high speed until the coating solution is dry to prepare a composite porous membrane (A).

[0040] Use the prepared composite membrane to assemble a neutral system zinc-iron flow battery, in which the catalytic layer is activated carbon felt, the bipolar plate is a graphite plate, and the effe...

Embodiment 2

[0052] Same as Example 1, the organic polymer resin is replaced by polysulfone, and other conditions remain unchanged.

Embodiment 3

[0054] Same as Example 1, the organic polymer resin is replaced by polyimide, the solvent is replaced by NMP, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com