Preparation method of alpha phase cobaltous hydroxide nanosheet for oxygen evolution reaction

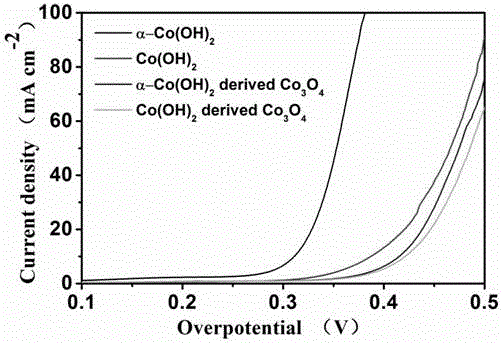

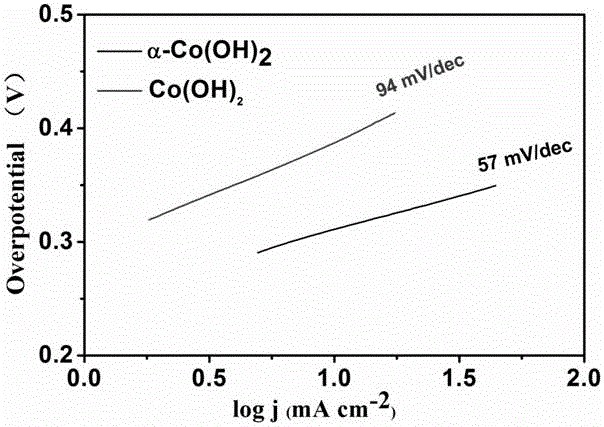

A cobalt hydroxide and oxygen evolution reaction technology is applied in the field of preparation of graphene-like two-dimensional materials and graphene-like two-dimensional nanomaterials, which can solve the problems of low current density, high overpotential, poor stability, etc. Good, simple operation, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

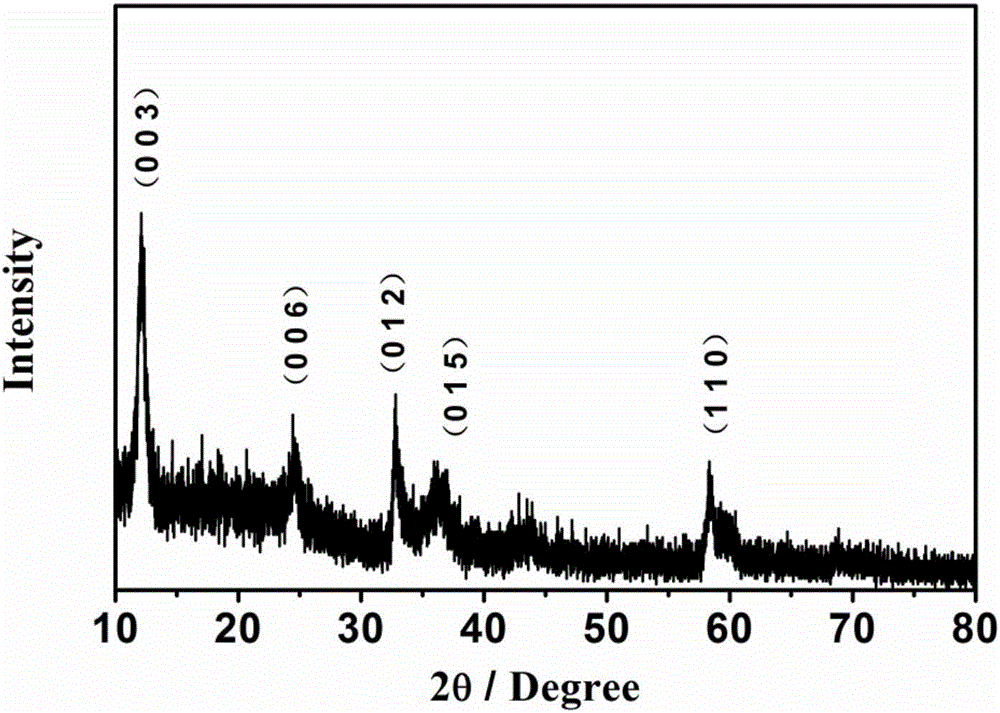

[0024] (1) Dissolve 1.6 g of cobalt chloride in 80 mL of deionized water, and 3.2 g of potassium hydroxide in 10 mL of deionized water.

[0025] (2) Transfer the solution obtained in step (1) to a glass vessel for mixing, heat and react under the condition of microwave power of 500W for 30 minutes, condense and reflux, and naturally cool to room temperature after the reaction is completed.

[0026] (3) Wash the material obtained in the previous step with deionized water and absolute ethanol successively, and then put it into a vacuum drying oven to dry to obtain alpha phase cobalt hydroxide nanosheets.

[0027] (4) Use the material synthesized in the previous step as a catalytic material for electrolysis of water (oxygen evolution reaction), and disperse the material in a mixed solution (the ratio of ethanol: deionized water is 1:1) and 5% nafion aqueous solution, in the mixed solution The ratio of mixed solution to nafion is 95:5. Apply the prepared solution on the surface o...

Embodiment 2

[0030] (1) Dissolve 2.1 g of cobalt nitrate in 60 mL of deionized water, and 3.2 g of sodium hydroxide in 40 mL of ethylene glycol.

[0031] (2) The solution obtained in step (1) was transferred to a glass vessel for mixing, heated and reacted at a microwave power of 700W for 15 minutes, condensed and refluxed, and naturally cooled to room temperature after the reaction was completed.

[0032] (3) Wash the material obtained in the previous step with deionized water and absolute ethanol successively, and then put it into a vacuum drying oven to dry to obtain alpha phase cobalt hydroxide nanosheets.

[0033] (4) Use the material synthesized in the previous step as a catalytic material for electrolysis of water (oxygen evolution reaction), and disperse the material in a mixed solution (the ratio of ethanol: deionized water is 1:1) and 5% nafion aqueous solution, in the mixed solution The ratio of mixed solution to nafion is 90:10. Apply the prepared solution on the surface of th...

Embodiment 3

[0035] (1) Dissolve 2.8 g of cobalt sulfate in 30 mL of deionized water, and 3.2 g of urea in a mixed solution of 45 mL of ethanol and 30 mL of ethylene glycol.

[0036] (2) Transfer the solution obtained in step (1) to a glass vessel for mixing, heat and react under microwave power of 600W for 180 minutes, condense and reflux, and naturally cool to room temperature after the reaction is completed.

[0037] (3) Wash the material obtained in the previous step with deionized water and absolute ethanol successively, and then put it into a vacuum drying oven to dry to obtain alpha phase cobalt hydroxide nanosheets.

[0038] (4) Use the material synthesized in the previous step as a catalytic material for electrolysis of water (oxygen evolution reaction), disperse the material in a mixed solution (the ratio of ethanol: deionized water is 1:1) and 5% nafion aqueous solution, and mix in the mixed solution The ratio of solution to nafion is 90:10. Apply the prepared solution on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com