A high-efficiency surface plasma visible-light-induced photocatalyst composite material (Ag@AgCl)-Ni/RGO having magnetic responsibility

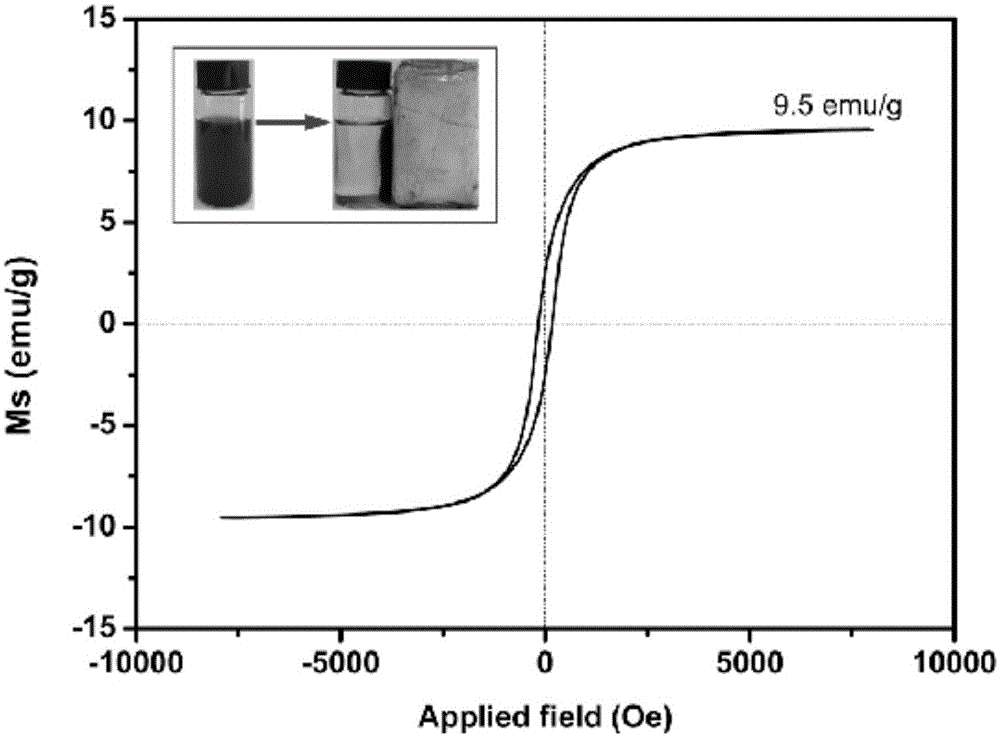

A surface plasmon, composite material technology, applied in the field of ionic visible light catalyst composite material-Ni/RGO, can solve the problems of affecting catalytic performance, low electrical conductivity, limiting charge migration, etc., to improve catalytic performance and good magnetic responsiveness. , the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of visible light catalyst composite (Ag@AgCl)-Ni / RGO

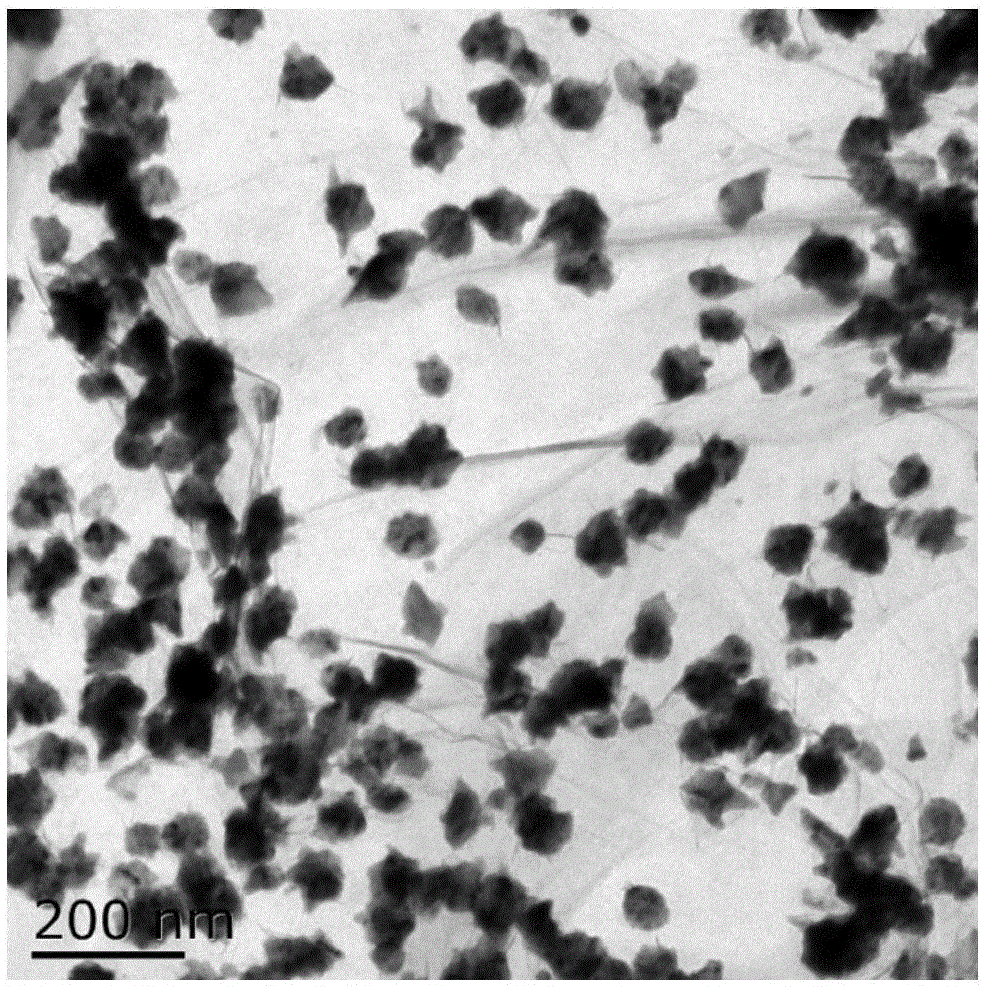

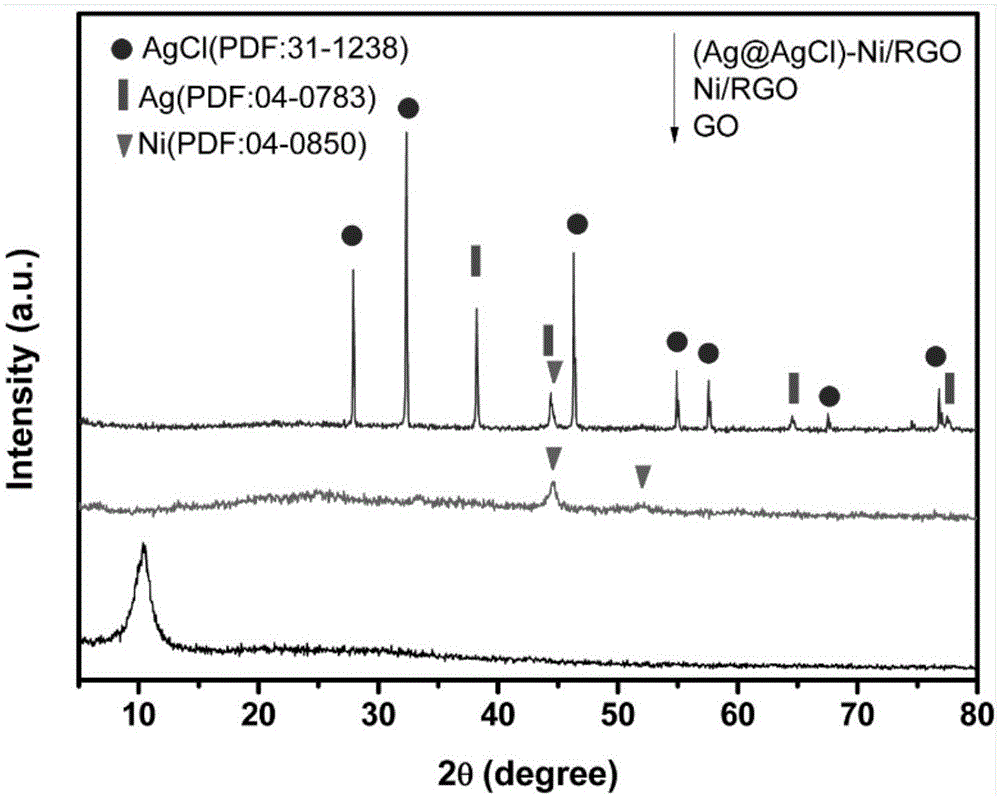

[0024] Weigh successively 0.05g graphite oxide (GO), 0.118g NiCl 2 ·6H 2 O, ultrasonic dispersion in 70mL ethylene glycol, ultrasonic time is 60min. Then, with the assistance of magnetic stirring, 10 mL of hydrazine hydrate (N 2 h 4 ·H 2 O, 80wt%) solution. After continuing to stir for 15 min, the mixture was transferred to a 100 mL reactor and reacted at 200°C for 45 min. After the solvothermal reaction was completed, the intermediate product was cooled at room temperature and washed repeatedly with ethanol and water to obtain a Ni / RGO composite material.

[0025] In a dark room environment, the intermediate product Ni / RGO was dispersed in 40mL containing 0.17g AgNO 3 After mechanical stirring for 30 min, 10 mL of an aqueous solution containing 0.059 g of NaCl was slowly added dropwise. After continuing to stir for 12 h in a dark room environment, irradiate with a 500W xenon lamp for ...

Embodiment 2

[0027] Example 2: Preparation of visible light catalyst composite (Ag@AgCl)-Ni / RGO

[0028] Weigh successively 0.05g graphite oxide (GO), 0.118g NiCl 2 ·6H 2 O, ultrasonic dispersion in 60mL ethylene glycol, ultrasonic time is 90min. Then, with the assistance of magnetic stirring, 10 mL of hydrazine hydrate ((N 2 h 4 ·H 2 O, 80wt%)) solution. After continuing to stir for 15 min, the mixture was transferred to a 100 mL reactor and reacted at 200°C for 60 min. After the solvothermal reaction was completed, the intermediate product was cooled at room temperature and washed repeatedly with ethanol and water to obtain a Ni / RGO composite material.

[0029] In a dark room environment, the intermediate product Ni / RGO was dispersed in 40mL containing 0.17g AgNO 3After mechanical stirring for 30 min, 10 mL of an aqueous solution containing 0.059 g of NaCl was slowly added dropwise. After continuing to stir for 12 h in a dark room environment, irradiate with a 500W xenon lamp for...

Embodiment 3

[0030] Example 3: Preparation of visible light catalyst composite (Ag@AgCl)-Ni / RGO

[0031] Weigh successively 0.05g graphite oxide (GO), 0.236g NiCl 2 ·6H 2 O, ultrasonic dispersion in 70mL ethylene glycol, ultrasonic time is 120min. Then, with the assistance of magnetic stirring, 10 mL of hydrazine hydrate (N 2 h 4 ·H 2 O, 80wt%) solution. After continuing to stir for 15 min, the mixture was transferred to a 100 mL reactor and reacted at 200°C for 45 min. After the solvothermal reaction was completed, the intermediate product was cooled at room temperature and washed repeatedly with ethanol and water to obtain a Ni / RGO composite material.

[0032] In a dark room environment, the intermediate product Ni / RGO was dispersed in 40mL containing 0.17g AgNO 3 After mechanical stirring for 60 min, 10 mL of an aqueous solution containing 0.059 g of NaCl was slowly added dropwise. After continuing to stir for 12 h in a dark room environment, irradiate with a 500W xenon lamp for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com