Preparation method for carbon nano-tube/silicon carbide heat-conducting composite material

A thermally conductive composite material and carbon nanotube technology, which is applied in the field of preparation of carbon nanotube/silicon carbide thermally conductive composite materials, can solve the problem that the interface between carbon nanotubes and silicon carbide substrates has weak bonding ability, reduces the thermal conductivity of composite materials, and affects composite materials. Mechanical properties and other issues, to achieve the effects of good antioxidant properties, good mechanical properties, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

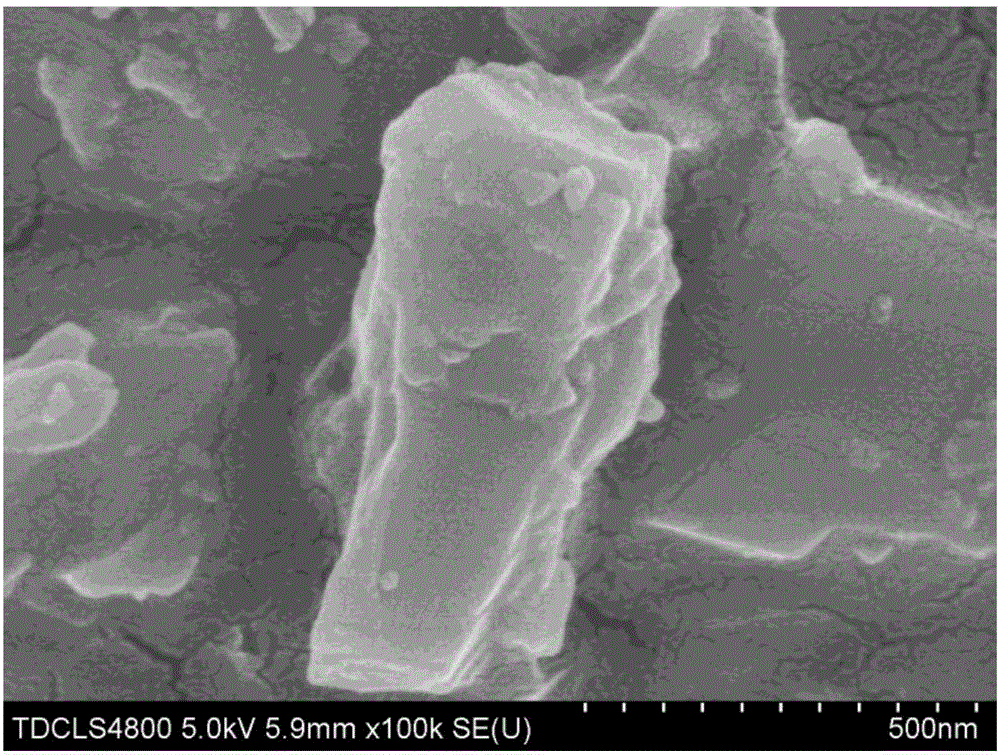

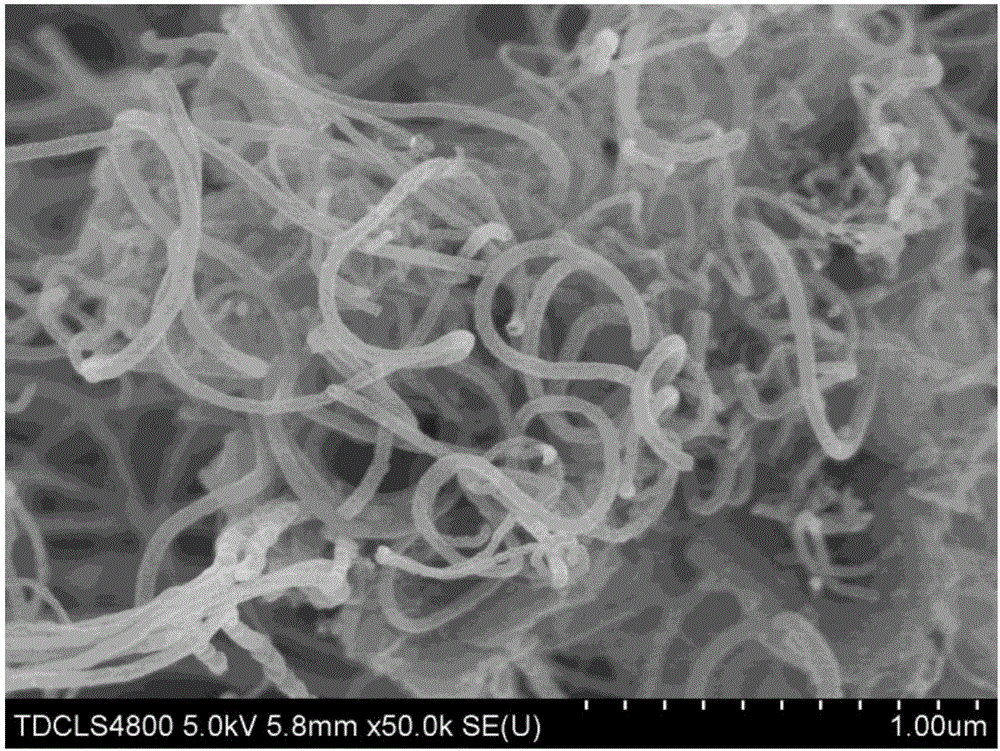

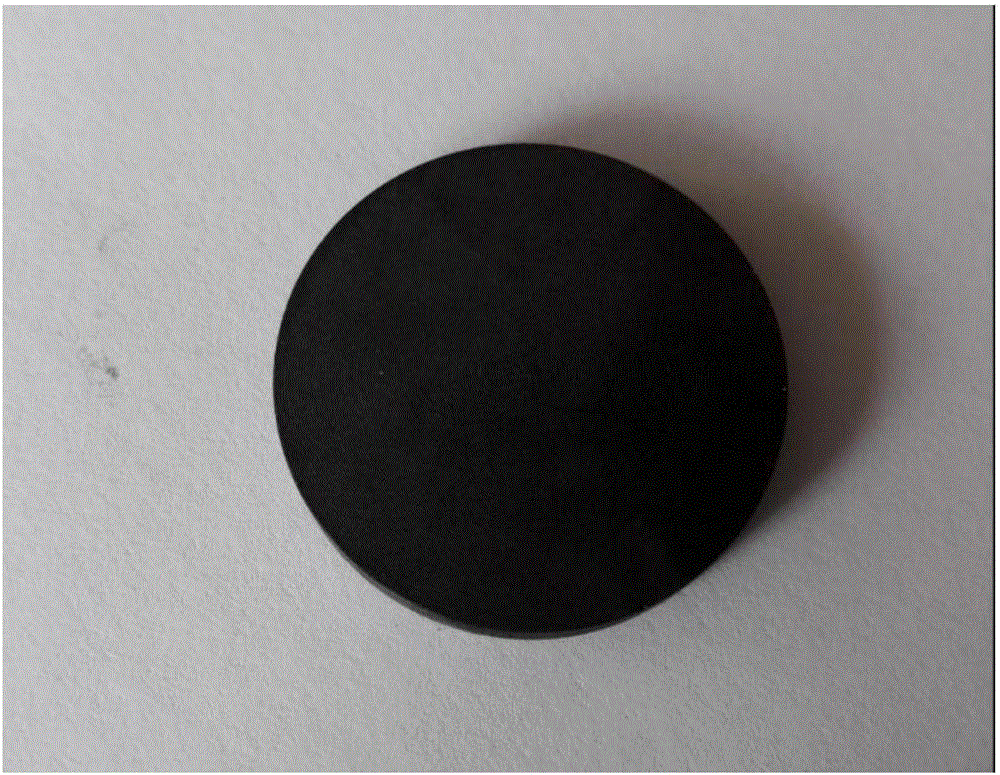

Embodiment 1

[0031] Place silicon carbide particles in a tube furnace; feed argon with a flow rate of 300 sccm and hydrogen with a flow rate of 30 sccm; heat up to 750°C; feed a mixed solution of carbon source and catalyst, wherein the carbon source is a mixed solution of ethanol and xylene , ethanol:xylene volume ratio=1:1, catalyst is ferrocene, is dissolved in the mixed solution of carbon source, and its concentration is 0.02g / ml, and injection speed is 15ml / h, and growth time is 10min; close H 2 Take out the silicon carbide with carbon nanotubes after cooling down; under the state of vacuum of 0.1MPa, immerse the polycarbosilane (PCS) solution of 0.3g / ml and the silicon carbide of growth carbon nanotubes for 20min; Form a block; pre-press the obtained silicon carbide block at a pressure of 35MPa and 180°C, then place the obtained green body in a mold, and place them together in a vacuum hot-pressing furnace for high-temperature hot-pressing, hot-pressing temperature At 1350°C, the hot...

Embodiment 2

[0033] Place silicon carbide particles in a tube furnace; feed argon with a flow rate of 350 sccm and hydrogen gas with a flow rate of 40 sccm; heat up to 800°C; feed a mixed solution of carbon source and catalyst, wherein the carbon source is a mixed solution of ethanol and xylene , ethanol:xylene volume ratio is=1:1, catalyst is ferrocene, is dissolved in the mixed solution of carbon source, and its concentration is 0.02g / ml, and injection speed is 18ml / h, and growth time is 30min; close H 2 Take out the silicon carbide with carbon nanotubes after cooling down; Under the state of vacuum degree of 0.1MPa, immerse the polycarbosilane (PCS) solution of 0.35g / ml and the silicon carbide of growth carbon nanotubes for 30min; Form a block; pre-press the obtained silicon carbide block at a pressure of 35MPa and 180°C, then place the obtained green body in a mold, and place them together in a vacuum hot-pressing furnace for high-temperature hot-pressing, hot-pressing temperature At ...

Embodiment 3

[0035] Put silicon carbide particles in a tube furnace; feed argon gas with a flow rate of 400 sccm and hydrogen gas with a flow rate of 40 sccm; heat up to 800°C; feed a mixed solution of carbon source and catalyst, wherein the carbon source is a mixed solution of ethanol and xylene , ethanol:xylene volume ratio is=1:1, catalyst is ferrocene, is dissolved in the mixed solution of carbon source, and its concentration is 0.025g / ml, and injection speed is 18ml / h, and growth time is 30min; close H 2Take out the silicon carbide with carbon nanotubes after cooling down; Under the state of vacuum of 0.1MPa, the polycarbosilane (PCS) solution of 0.4g / ml and the silicon carbide of growth carbon nanotubes are impregnated for 40min; Form a block; pre-press the obtained silicon carbide block at a pressure of 40 MPa and 180°C, then place the obtained green body in a mold, and place them together in a vacuum hot-pressing furnace for high-temperature hot-pressing, hot-pressing temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com