Preparation method of urea-wrapped cellulose-based super absorbent resin

A technology of water-absorbent resin and cellulose, which is applied in the field of material engineering, can solve the problems of low fertilizer adsorption and slow-release effect, and achieve the effects of improving the slow-release effect, increasing the adsorption amount, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

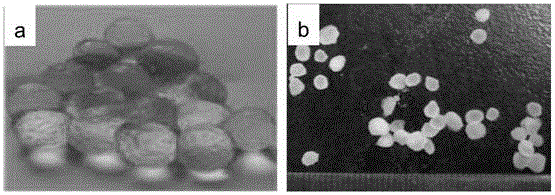

Image

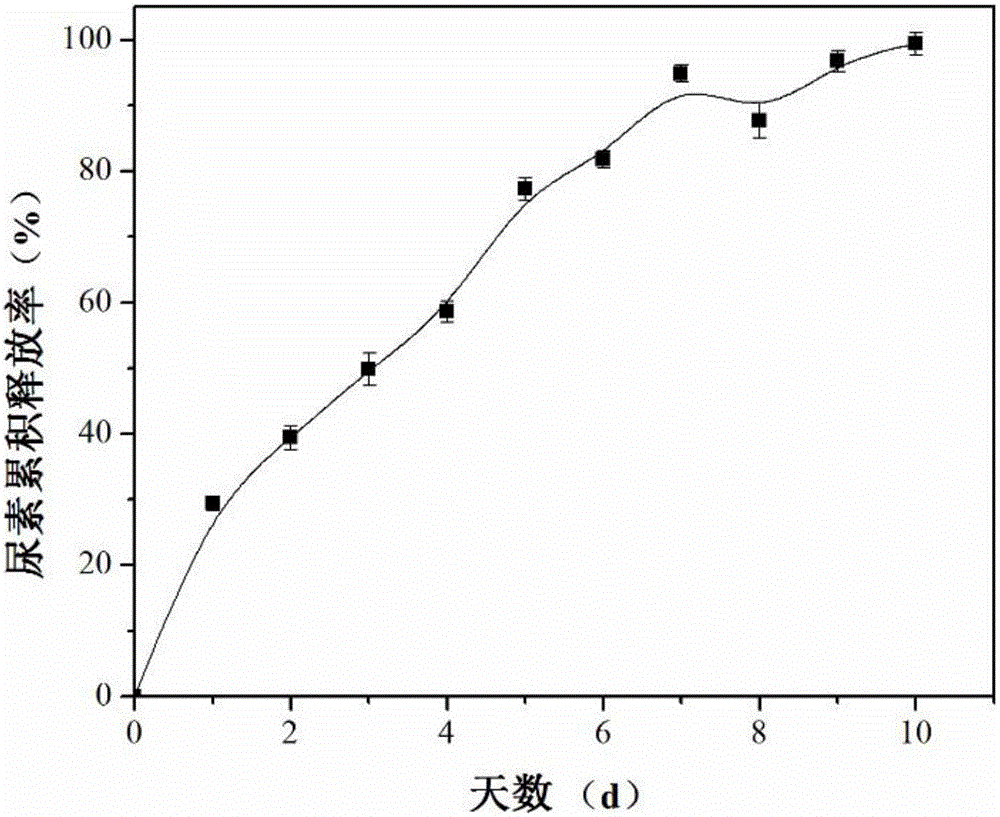

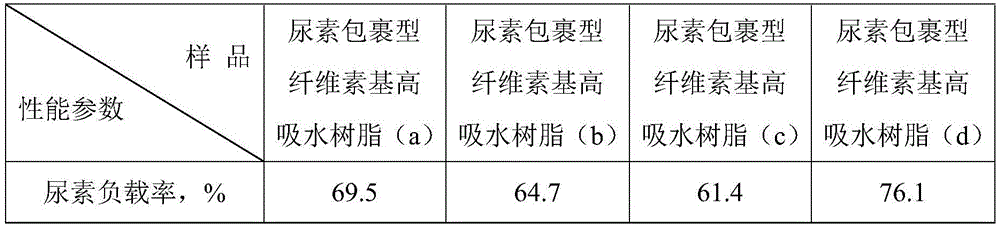

Examples

Embodiment 1

[0021] 1) After crushing and sieving, the plant cellulose powder of pine wood with a particle size of ≤0.2mm is added to the deionized water to fully dissolve according to the reaction mass ratio of plant cellulose powder and deionized water of 1:35, and then the solution is transferred Put it into a three-necked flask with a condenser and a nitrogen device, heat and stir in a water bath at 75°C, and feed nitrogen at the same time; after 35 minutes, add ammonium persulfate according to the reaction mass ratio of plant cellulose powder and ammonium persulfate 1:0.4 The solution triggers free radicals. After 4 minutes, the reaction mass ratio of acrylamide to acrylic acid solution is 1:7, the reaction mass ratio of plant cellulose powder to the sum of acrylamide and acrylic acid is 1:12, and the reaction mass ratio of plant cellulose powder to N,N- The reaction mass ratio of methylbisacrylamide 1:0.07 is added in turn to the acrylic acid solution, acrylamide solution, and N,N-met...

Embodiment 2

[0024] 1) Add the plant cellulose powder of cypress with a particle size of ≤0.2mm after crushing and sieving to fully dissolve in deionized water according to the reaction mass ratio of plant cellulose powder and deionized water of 1:40, and then transfer the solution Put it into a three-necked flask with a condenser tube and a nitrogen device, heat and stir in a water bath at 85°C, and feed nitrogen at the same time; after 30 minutes, add ammonium persulfate according to the reaction mass ratio of plant cellulose powder and ammonium persulfate 1:0.25 The solution triggers free radicals. After 3 minutes, the reaction mass ratio of acrylamide to acrylic acid solution is 1:6, the reaction mass ratio of plant cellulose powder to the sum of acrylamide and acrylic acid is 1:12, and the reaction mass ratio of plant cellulose powder to N,N- The reaction mass ratio of methylbisacrylamide 1:0.06 was added in turn to the acrylic acid solution, acrylamide solution, and N,N-methylenebisac...

Embodiment 3

[0027] 1) After pulverization and sieving, the plant cellulose powder of Chinese fir with a particle size of ≤0.2mm is added to the deionized water to fully dissolve according to the reaction mass ratio of plant cellulose powder and deionized water of 1:35, and then the solution is transferred Put it into a three-necked flask with a condenser tube and a nitrogen device, heat and stir in a water bath at 80°C, and feed nitrogen at the same time; after 25 minutes, add ammonium persulfate according to the reaction mass ratio of plant cellulose powder and ammonium persulfate 1:0.35 The solution triggers free radicals. After 4 minutes, the reaction mass ratio of acrylamide to acrylic acid solution is 1:5, the reaction mass ratio of plant cellulose powder to the sum of acrylamide and acrylic acid is 1:11, and the reaction mass ratio of plant cellulose powder to N,N- The reaction mass ratio of methylbisacrylamide 1:0.07 is added in turn to the acrylic acid solution, acrylamide solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com