A genetically engineered bacterium producing 2-phenylethanol and an applying method thereof

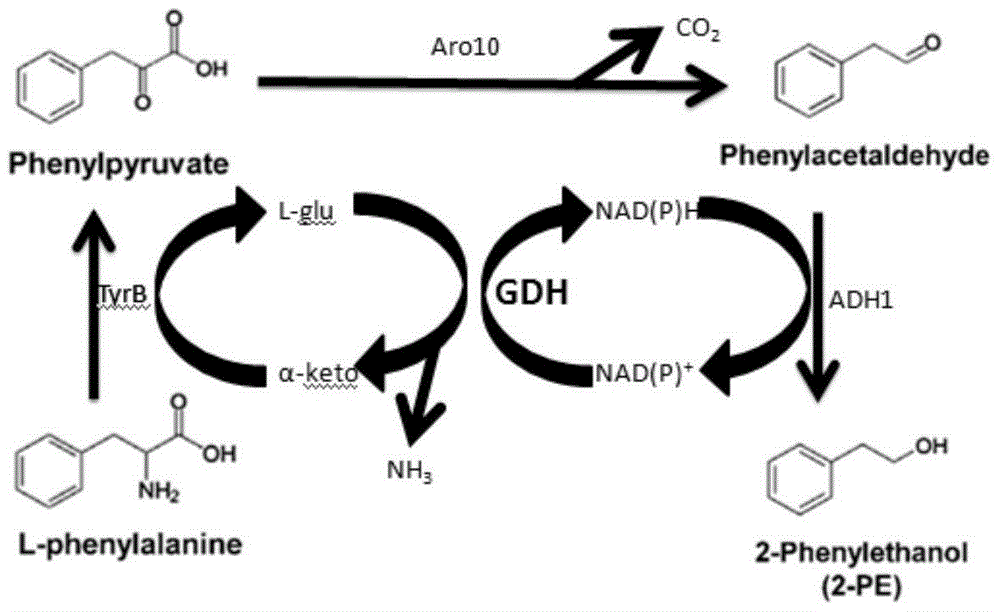

A phenethyl alcohol and coding gene technology, which is applied in the field of biological genetic engineering, can solve the problems of low purity, low 2-phenylethyl alcohol content, and cannot meet the requirements of food grade, etc., and achieves improved circulation efficiency, short production cycle, and improved synthesis. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, the construction of recombinant bacteria

[0048] 1. Construction of recombinant plasmids

[0049] (1) Construction of recombinant plasmids for 2-phenylethanol production

[0050] 1. Construction of recombinant plasmid PEA31

[0051] Using the genome of Escherichia coli str.K-12 as a template, a pair of primers were designed to amplify the gene encoding aromatic amino acid aminotransferase (tyrB), with a fragment size of about 1200bp. After sequencing analysis, the results showed that the amplified gene The nucleotide sequence of tyrB is shown in sequence 10 in the list, and the amino acid sequence of the aromatic amino acid aminotransferase encoded by the nucleotide sequence is shown in sequence 1 in the sequence listing.

[0052] Using the Saccharomyces cerevisiae genome as a template, a pair of primers were designed to amplify the gene encoding phenylpyruvate decarboxylase (aro10), with a fragment size of about 1900 bp. After sequencing analysis, the ...

Embodiment 2

[0117] Embodiment 2, recombinant bacterium whole cell catalytic preparation 2-phenylethanol

[0118] 1. Induction of recombinant bacteria

[0119] Self-induction culture: Streak the recombinant bacteria on an LB plate containing 1.5% mass percent agar and 50 μg / mL streptomycin, and culture at 37° C. for 12 hours. Pick the single clone grown on the plate, inoculate it into liquid LB medium containing 50 μg / mL streptomycin, and cultivate overnight at 37°C with shaking at 220 rpm; Inoculate a large amount into the self-inducing medium ZYM, culture with shaking at 20°C, rotate at 220rpm, and culture for 24h.

[0120] The formula of autoinduction medium ZYM is as follows: 100mL A+2mL B+2mL C+200μL D+100μL E.

[0121] The following are mass percentage concentrations:

[0122] A.ZY: 1% tryptone, 0.5% yeast powder;

[0123] B.50×M: 1.25M Na 2 HPO 4 , 1.25M KH 2 PO 4 , 2.5M NH 4 Cl and 0.25M Na 2 SO 4 ;

[0124] C.50×5052: 25% glycerol, 2.5% glucose, 10% L-arabinose;

[01...

Embodiment 3

[0134] Embodiment 3, whole cell catalyzed preparation of 2-phenylethanol by different engineering strains

[0135] The amount of 2-phenylethanol in mM mentioned in this example refers to the concentration of 2-phenylethanol in the transformation system.

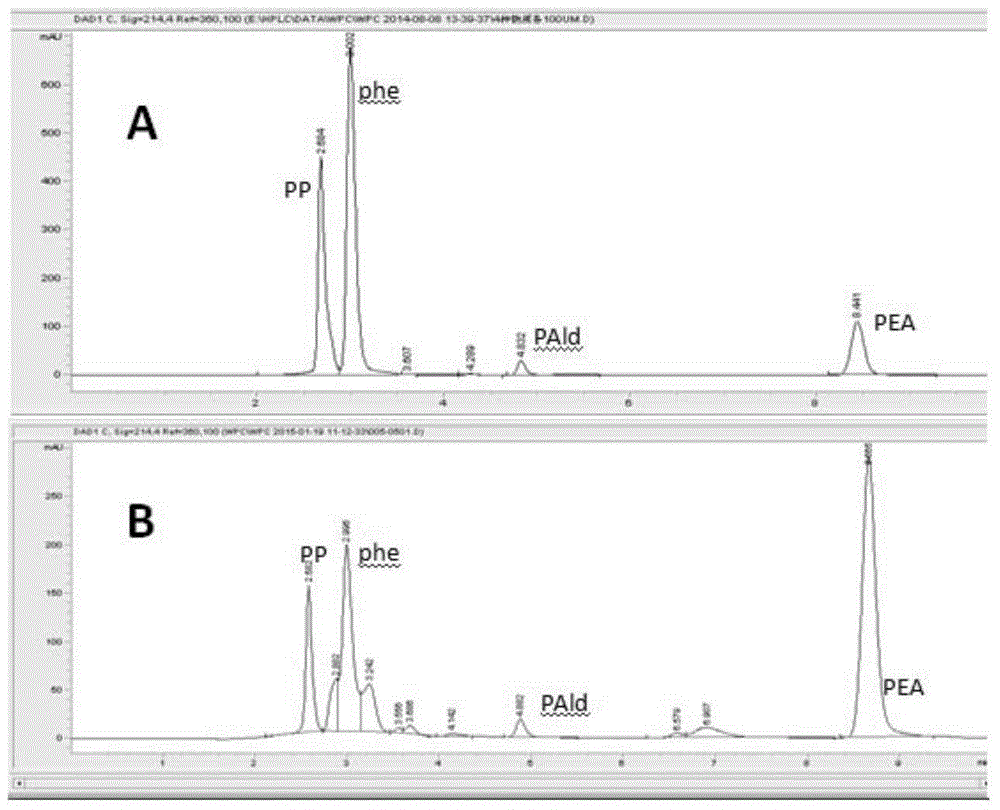

[0136] 1. PEA31B whole cell transformation to produce 2-phenylethanol

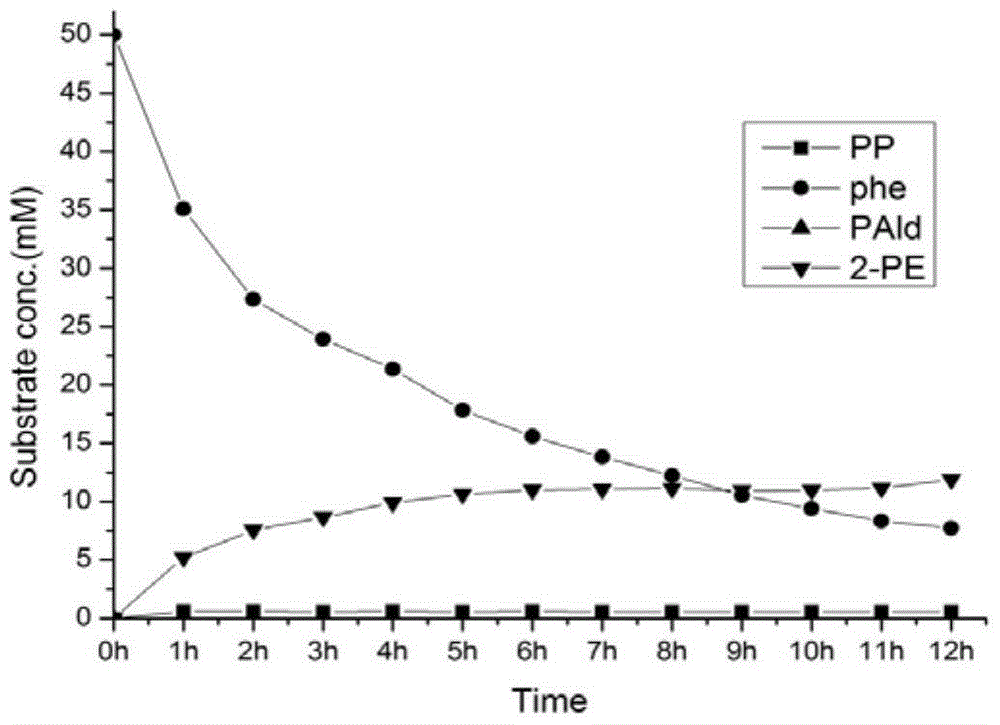

[0137] The strain PEA31B was used to induce protein expression according to the method in Example 2, and the basic transformation solution was used to transform whole cells into 2-phenylethanol. The synthesis amount of the product 2-phenylethanol (PEA) gradually increased with time, and after 6 hours, the accumulation amount of 2-phenylethanol remained basically unchanged ( image 3 ).

[0138] 2. Transformation of whole cells of PEA31B, PEA32B, and PEA33B to produce 2-phenylethanol

[0139] Use the strains PEA31B, PEA32B, and PEA33B to induce protein expression according to the method in Example 2, and use the basic transformation solution to conduct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com