MoS2/TiO2NTs heterojunction photo-electro-catalyst substituting noble metal Pt sheet for hydrogen evolution and preparation method of MoS2/TiO2NTs heterojunction photo-electro-catalyst

A technology of noble metals and catalysts, applied in the field of photoelectric catalysts, can solve the problems that are difficult to be widely used in industrial production, and achieve the effect of increasing reaction active sites, simple method and process, and increasing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

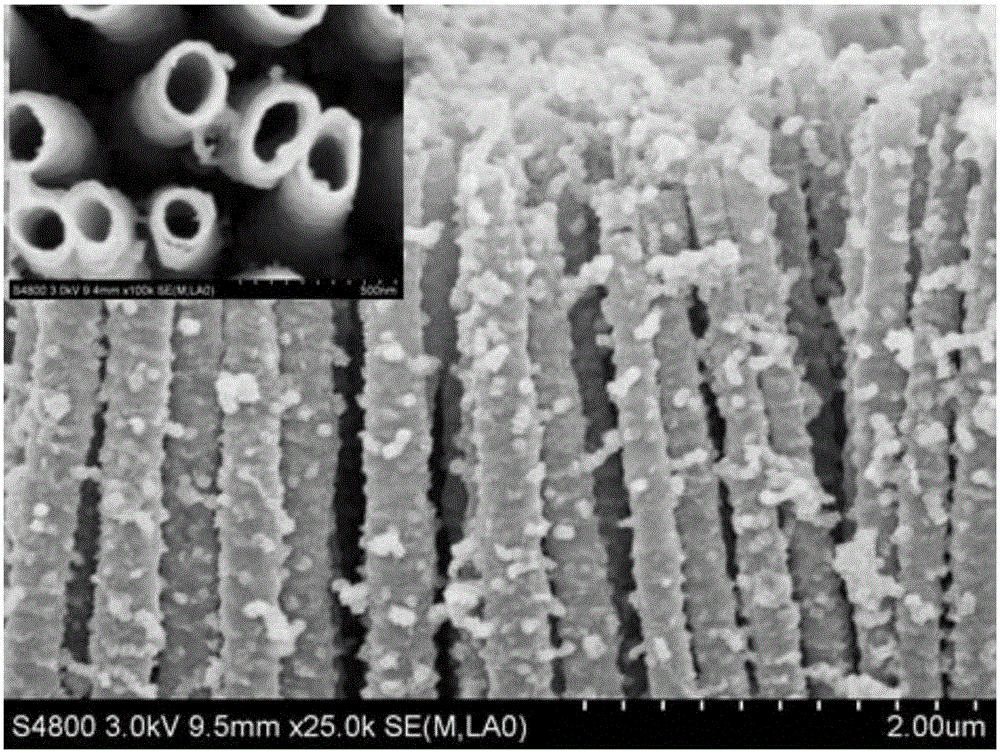

[0028] The industrial titanium sheet was cut to a size of 33×20×0.3mm, pressed to make it flat, ultrasonically cleaned with acetone, ethanol, and ultrapure deionized water for 20 minutes, and immersed in ultrapure deionized water for storage until use. Prepare a fresh diethylene glycol (DEG) mixed solution with a concentration of 1% HF before preparation, take out the pretreated titanium sheet and dry it, and use it as an anode to immerse it in the prepared electrolytic solution with an effective electrolytic area of 20×20mm. The cathode uses a 20×20×0.1mm platinum sheet electrode, connected to a DC power supply, adopts a constant voltage DC electrolysis method, adjusts the voltage to 60V, and controls the electrolysis time to 120h. After the anodizing process is over, turn off the power, and the surface will grow TiO 2 The titanium sheet of the nanotube array was taken out and washed in ultra-pure deionized water, dried, put into a muffle furnace and calcined at 450°C for 2...

Embodiment 2

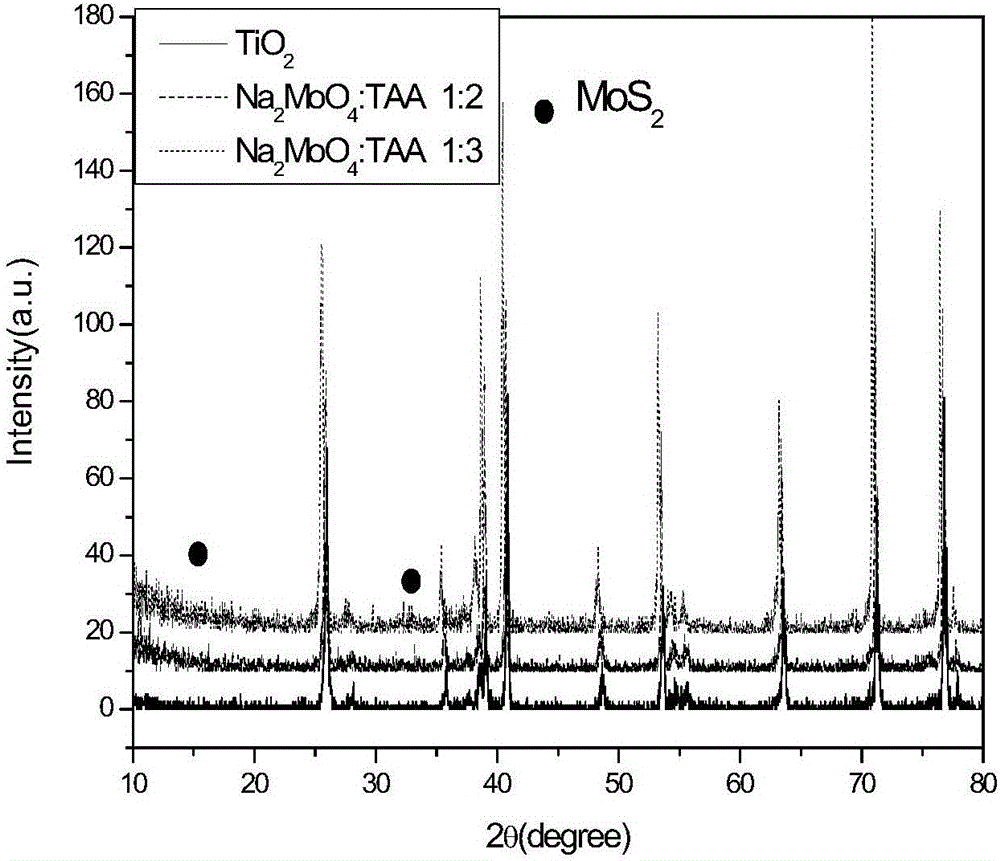

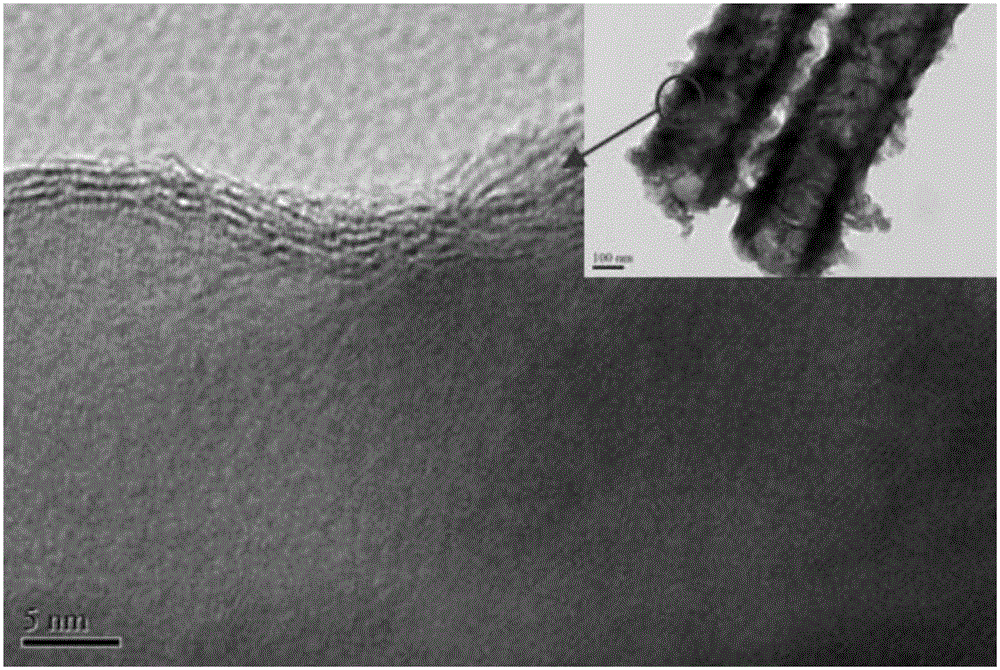

[0030] Weigh 10 mg of sodium molybdate (Na 2 MoO 4 ) and 20mg of thioacetamide (TAA) were dissolved in 20ml of DEG, stirred for 20min, and put into the prepared spacing TiO 2 nanotube array, put it in an oven at 200°C for 24 hours, wash the black electrode three times with water and ethanol, and then dry it in vacuum at 80°C to obtain the catalyst MoS 2 / TiO 2 array of nanotubes.

Embodiment 3

[0032] Weigh 10 mg of sodium molybdate (Na 2 MoO 4 ) and 30mg of thioacetamide (TAA) were dissolved in 20ml of DEG, stirred for 20min, and put into the prepared spacing TiO 2 nanotube array, put it in an oven at 200°C for 24 hours, wash the black electrode three times with water and ethanol, and then dry it in vacuum at 80°C to obtain the catalyst MoS 2 / TiO 2 array of nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com