Carbon nitride hollow sphere photocatalyst, preparation method and application thereof

A technology of photocatalyst and hollow sphere, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of simplifying the synthesis process, good photocatalytic performance, reducing environmental pollution and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

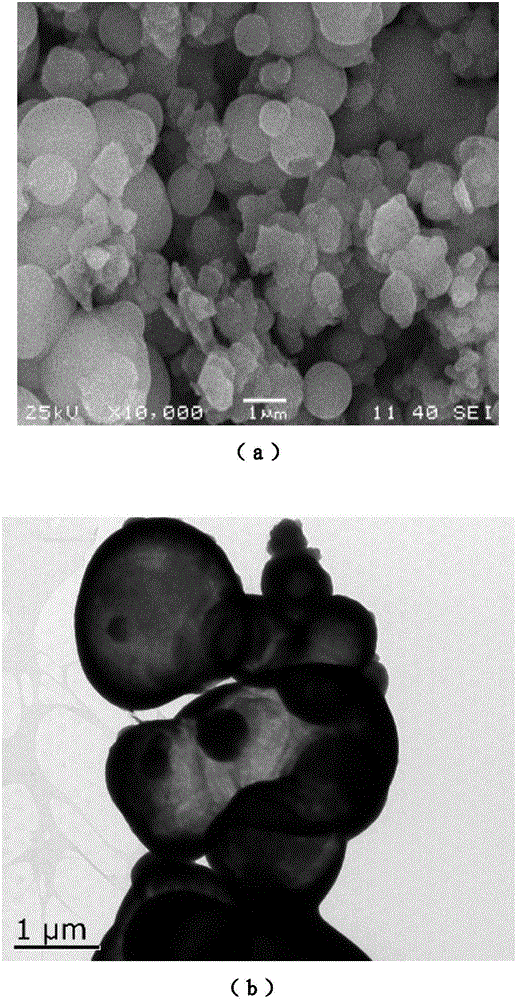

Embodiment 1

[0043]Disperse cyanuric chloride and dicyanuric amine (mass ratio: 1:0.34) in acetonitrile (the ratio of cyanuric chloride to acetonitrile is 1g: 22mL), and stir the mixture at room temperature for 12h at a speed of 500r / min. The mixture was transferred to a hydrothermal reactor and heat-treated at a constant temperature of 180 °C for 72 h. Naturally cooled to room temperature, the resulting solid precipitate was collected by centrifugation, washed twice with absolute ethanol, and then washed with distilled water. The washed precipitate was dried at a temperature of 50° C. for 12 hours to obtain a dried precipitate to obtain a carbon nitride hollow sphere photocatalyst.

Embodiment 2

[0045] Disperse cyanuric chloride and dicyanuric amine (mass ratio: 1:0.34) in acetonitrile (the ratio of cyanuric chloride to acetonitrile is 1g: 22mL), and stir the mixture at room temperature for 12h at a speed of 500r / min. The mixed solution was transferred to a hydrothermal reactor and heat-treated at a constant temperature of 180° C. for 96 h. Naturally cooled to room temperature, the resulting solid precipitate was collected by centrifugation, washed twice with absolute ethanol, and then washed with distilled water. The washed precipitate was dried at a temperature of 90° C. for 6 hours to obtain a dried precipitate, which was a carbon nitride hollow sphere photocatalyst.

Embodiment 3

[0047] Disperse cyanuric chloride and dicyanuric amine (mass ratio 1:0.34) in acetonitrile (the ratio of cyanuric chloride to acetonitrile is 1g: 20mL), and stir the mixture under reflux at 70°C for 6 hours at a controlled speed. 600r / min. The mixed solution was transferred to a hydrothermal reactor and heat-treated at a constant temperature of 180° C. for 48 h. Naturally cooled to room temperature, the resulting solid precipitate was collected by centrifugation, washed twice with absolute ethanol, and then washed with distilled water. The washed precipitate was dried at a temperature of 70° C. for 10 h to obtain a dried precipitate, which was a carbon nitride hollow sphere photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com