A kind of production method of nano cesium tungstate powder

A production method, nano-tungsten technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost, complicated washing process, and long time, and achieve low cost, convenient industrial production, and safe process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

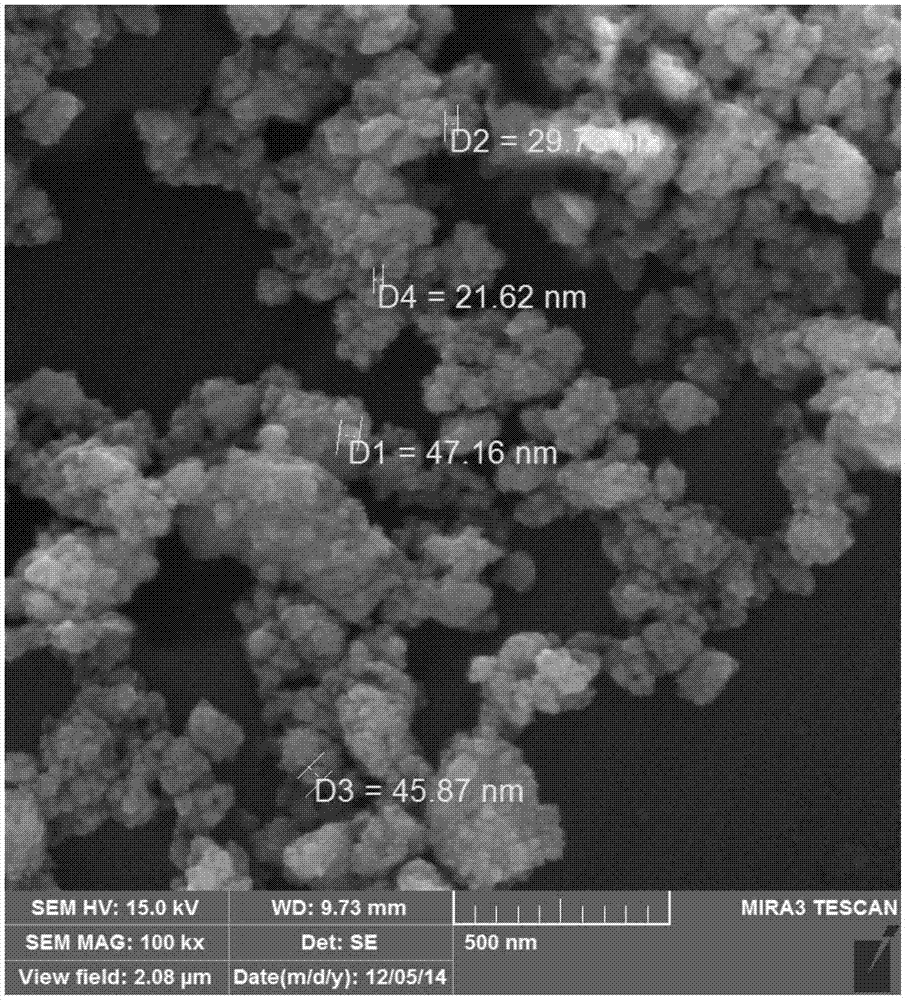

Embodiment 1

[0030] 100g of ammonium paratungstate is dissolved in 200g of water, 15g of cesium carbonate is dissolved in 10g of water, 100g of urea is dissolved in 200g of water, and the above solution is sequentially added to 2000ml of mixed solvent of ethanol and ethyl alcohol (ethanol: ethyl acetate volume ratio is 1:1), stir well, heat at 110°C, concentrate and dry (distillate is condensed and recovered), cool and grind, dry product is ground and roasted at 400°C for 6 hours, cool and grind, add to a 500ml autoclave, add 300ml of water, seal and heat and stir React (160° C.) for 4 hours, cool and discharge, filter, and dry the filter mud at 100° C. (10 hours) and pulverize to obtain 96 grams of blue nano cesium tungstate powder.

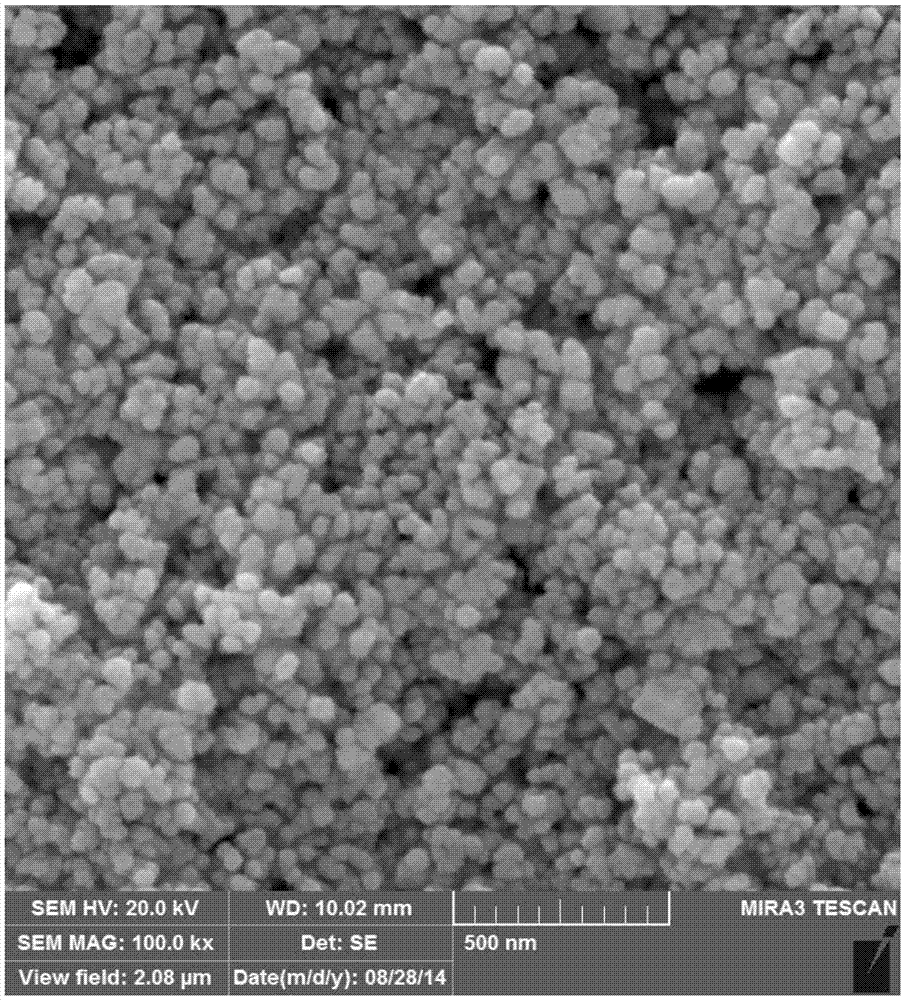

Embodiment 2

[0032] Dissolve 100g of ammonium metatungstate in 60ml of water, dissolve 13g of cesium carbonate in 10g of water, dissolve 5g of PVP in 20g of water, and add the above solutions in turn to a mixed solvent (600ml) of methanol and butyl acetate, (ethanol: butyl acetate Ester volume ratio = 1:3), stir evenly, heat at 80°C to concentrate and dry (distillate is condensed and recovered) to obtain a dry product, roast at 500°C for 2 hours, cool and pulverize the roasted product, add to a 500ml autoclave, add 400ml of water, seal , heated and stirred for reaction (250° C., 3 hours), cooled and discharged, filtered, dried at 80° C. (12 hours) and pulverized to obtain 101 grams of blue nano cesium tungstate powder product.

Embodiment 3

[0034] Dissolve 200g of ammonium metatungstate in 120g of water, dissolve 22g of cesium hydroxide in 20g of water, and dissolve 100g of ammonium oxalate in 200g of water.

[0035] Add the above three aqueous solutions in sequence to the mixed solution (800ml) composed of ethanol and ethylene glycol monopropyl ether (volume ratio = 1:1), stir well, heat to less than 120°C, concentrate and dry (distillate is condensed and recovered) to obtain Dry product, crushed, roasted at 600°C for 2 hours, cooled and crushed the roasted product, put it into a 500ml autoclave, added 300ml of water, sealed, heated and stirred for reaction (200°C, 8 hours), cooled and discharged, filtered, and dried at 120°C for 8 hours, Pulverize to obtain 203 grams of blue nano cesium tungstate powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com