Method for preparing L-alanine by taking hydroxyproline wastewater as raw material

The technology of hydroxyproline and alanine is applied in the field of hydroxyproline waste water reuse, and can solve the problems such as many types of impurities in L-alanine, complicated L-alanine process, and many impurity amino acids, etc. To achieve the effect of sustainable development, good production and operation environment, and simple refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

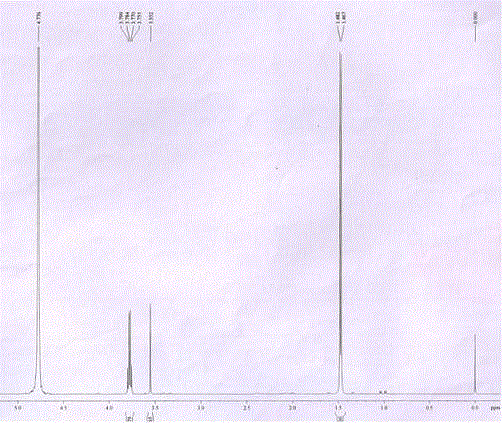

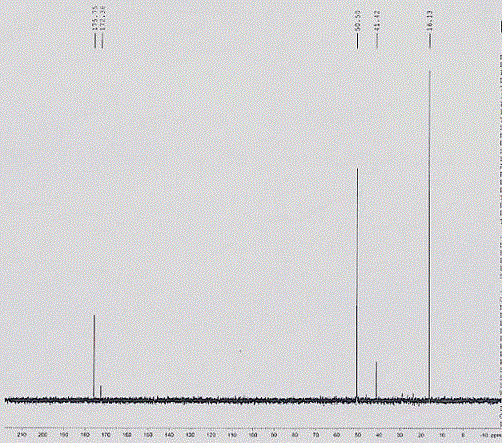

Image

Examples

Embodiment 1

[0021] This embodiment relates to a method for preparing L-alanine from hydroxyproline wastewater, which specifically includes the following steps:

[0022] a. Take hydroxyproline waste water, put it in the reactor at a high temperature of 110°C, react for 6 hours, and centrifuge the solution to obtain L-alanine mother liquor;

[0023] b. Decolorize the mother liquor obtained in step a with 3% (mass fraction) food-grade activated carbon added at 65°C for 2 hours, filter to obtain a colorless and transparent solution, and concentrate under reduced pressure to obtain a solid;

[0024] c. Add "methanol+water" to the solid obtained in step b, wherein the mass ratio of methanol:water=90:10, dissolve at 55°C for 2 hours, filter and dry to obtain crude L-alanine;

[0025] d. Recrystallize the crude L-alanine obtained in step c, prepare a saturated aqueous solution of L-alanine at 65°C, fully dissolve it for 2 hours, and add absolute ethanol at a dropping rate of 1 g / min until it is i...

Embodiment 2

[0027] This embodiment relates to a method for preparing L-alanine from hydroxyproline wastewater, which specifically includes the following steps:

[0028] a. Take hydroxyproline waste water, put it in the reactor at a high temperature of 100° C., react for 7 hours, and centrifuge the solution to obtain L-alanine mother liquor.

[0029] b. Decolorize the water obtained in step a with 0.5% (mass fraction) food-grade activated carbon added at 60°C for 3 hours, filter to obtain a colorless and transparent solution, and concentrate under reduced pressure to obtain a solid.

[0030] c. Add "absolute ethanol + water" to the solid obtained in step b, wherein absolute ethanol:water=92:8. Dissolve at 60°C for 3h, filter and dry to obtain crude L-alanine.

[0031] d. Recrystallize the crude L-alanine obtained in step c, prepare a saturated aqueous solution of L-alanine at 70°C, fully dissolve it for 2 hours, and add isopropanol at a dropping rate of 3g / min until it is in the solution ...

Embodiment 3

[0033] This embodiment relates to a method for preparing L-alanine from hydroxyproline wastewater, which specifically includes the following steps:

[0034] a. Take hydroxyproline waste water, put it in the reactor at a high temperature of 80°C, react for 8 hours, and centrifuge the solution to obtain L-alanine mother liquor.

[0035] b. Take the gelatin wastewater, decolorize it with 1% (mass fraction) food-grade activated carbon at 65°C for 1.5 hours, filter to obtain a colorless and transparent solution, and concentrate under reduced pressure to obtain a solid.

[0036] c. Add "n-butanol + water" to the solid obtained in step a, wherein n-butanol:water=95:5. Dissolve at 50°C for 2h, filter and dry to obtain crude L-alanine.

[0037] d. Recrystallize the crude L-alanine obtained in step b, prepare a saturated aqueous solution of L-alanine at 55°C, fully dissolve it for 2 hours, and add isopropanol at a dropping rate of 3g / min until it is in the solution When fine crystals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com