Low air-entraining type maleic anhydride poly carboxylic acid water reducing agent and preparation method thereof

A technology of maleic anhydride and polycarboxylic acid, which is applied in the field of concrete admixtures, can solve the problems of large air-entraining volume, high concrete viscosity, poor concrete appearance, etc., and achieve easy industrialization, high viscosity and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

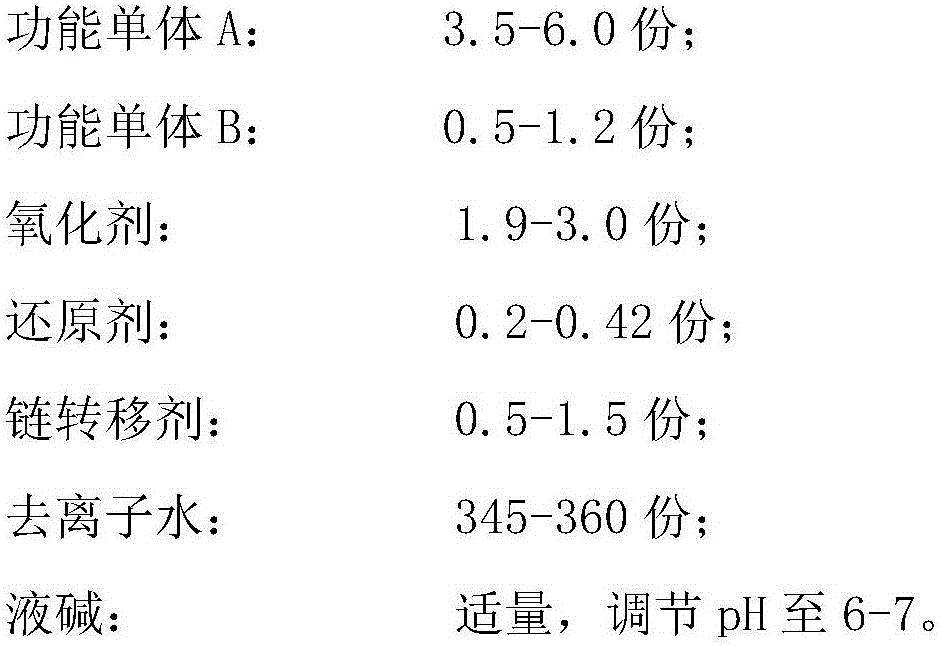

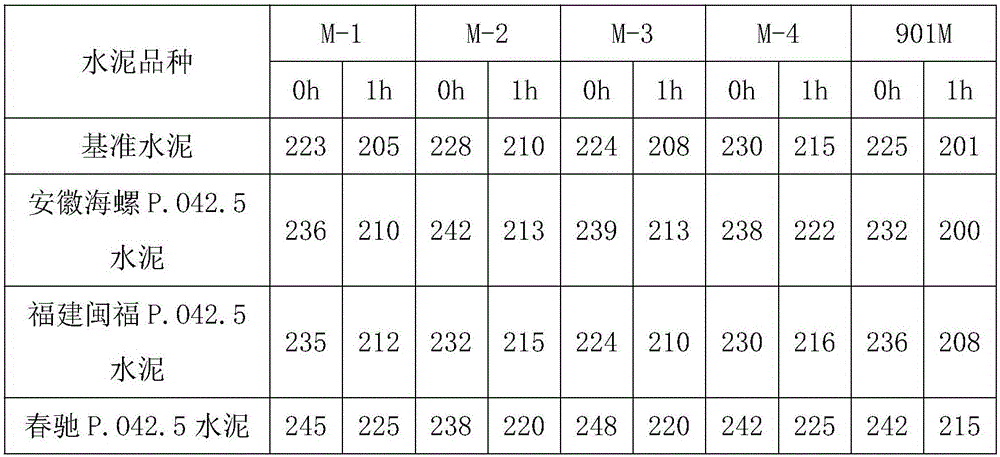

[0025] Embodiment 1: The preparation method of low air-entraining type maleic anhydride polycarboxylate water reducer

[0026] Add 200 parts of TPEG, 15 parts of maleic anhydride and 284 parts of deionized water into the reactor, stir at room temperature until completely dissolved, add 1.9 parts of hydrogen peroxide at one time, stir for 5 minutes, and then dropwise add 2 parts of N - A mixed solution of vinylpyrrolidone, 2.75 parts of methyl methacrylate, 0.85 parts of octanol and 36 parts of deionized water, and a mixed solution of 0.2 parts of vitamin C, 1.0 parts of mercaptopropionic acid and 40 parts of deionized water , the dropping time is 2.5-3.5 hours, continue to react for 1-2 hours after dropping, and then adjust the pH to 6-7 with liquid caustic soda to obtain low air-entraining maleic anhydride polycarboxylate superplasticizer, record the sample for M-1.

[0027] Deionized water was added three times; the deionized water added to the reactor for the first time wa...

Embodiment 2

[0028] Embodiment 2: the preparation method of low air-entraining type maleic anhydride polycarboxylate water reducer

[0029] Add 200 parts of TPEG, 18 parts of maleic anhydride and 270 parts of deionized water into the reactor, stir at room temperature until completely dissolved, add 2.45 parts of ammonium persulfate at one time, stir for 5 minutes, and then dropwise add 1.5 parts of A mixed solution of N-vinyl caprolactam, 2 parts of butyl acrylate, 0.5 parts of lauryl alcohol and 35 parts of deionized water, and a mixed solution of 0.31 parts of saffron, 0.5 parts of thioglycolic acid and 40 parts of deionized water , the dropping time is 2.5-3.5 hours, continue to react for 1-2 hours after dropping, and then adjust the pH to 6-7 with liquid caustic soda to obtain low air-entraining maleic anhydride polycarboxylate superplasticizer, record the sample for M-2.

Embodiment 3

[0030] Embodiment 3: the preparation method of low air-entraining type maleic anhydride polycarboxylate water reducer

[0031] Add 200 parts of TPEG, 22 parts of maleic anhydride and 280 parts of deionized water into the reactor, stir at room temperature until completely dissolved, add 3 parts of potassium persulfate at one time, stir for 5 minutes, and then dropwise add 2.5 A mixed solution of N-vinyl caprolactam, 3.5 parts of methyl methacrylate, 1.2 parts of dodecyl alcohol and 35 parts of deionized water, and a mixture of 0.42 parts of chalk, 1.5 parts of mercaptopropionic acid and 40 parts of deionized water Mix the solution, drop it for 2.5-3.5 hours, continue to react for 1-2 hours after the drop, and then adjust the pH to 6-7 with liquid caustic soda to obtain a low air-entraining maleic anhydride polycarboxylate superplasticizer. Record the sample as M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com