Efficient chlorobenzene degradation obligate bacterium, composite microbial agent and preparation method and application of composite microbial agent

A technology of composite microbial agent and composite strain, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as unstable operation, high technical requirements, and long microbial domestication cycle, and achieve shortened degradation The time required, beneficial to long-term storage, and the effect of improving the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

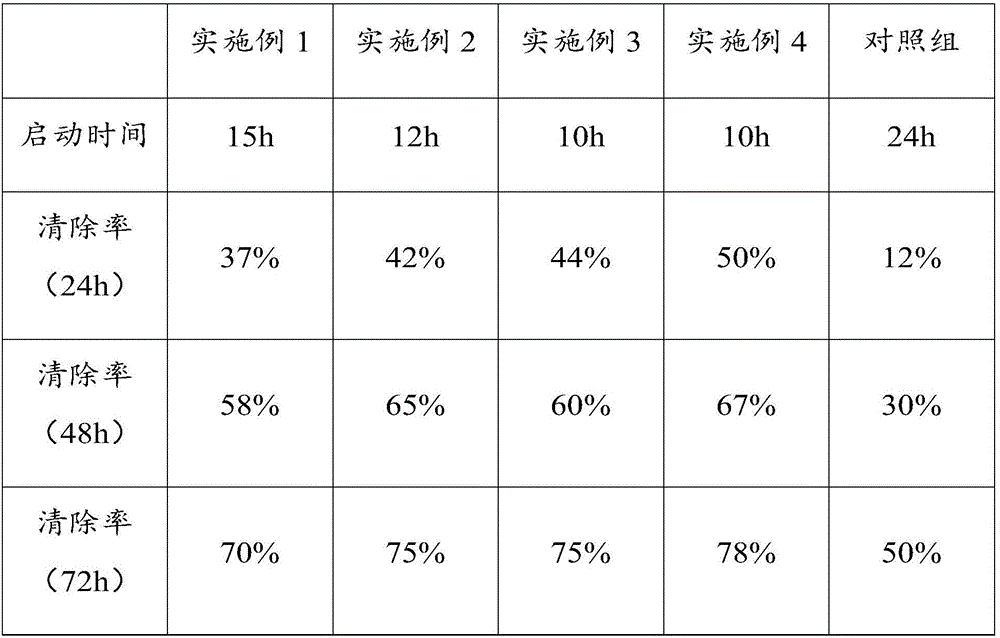

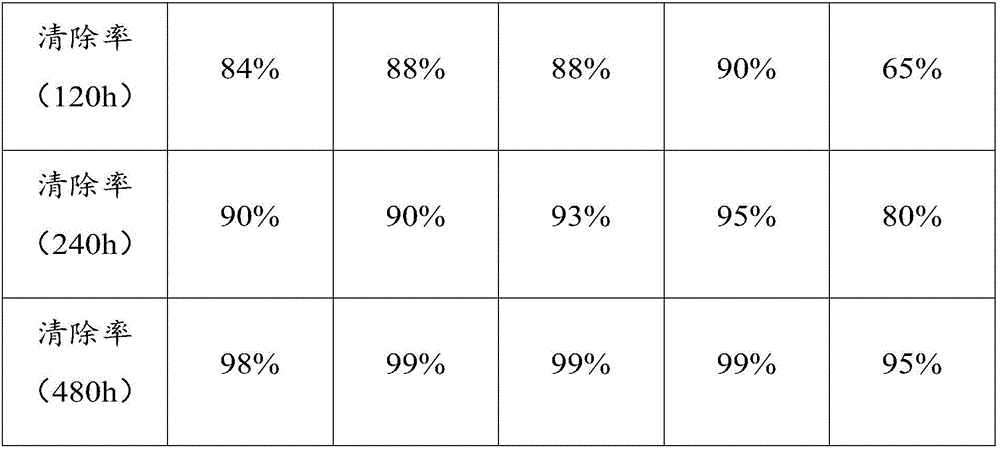

Embodiment 1

[0035] Add 250mg, 500mg, 1000mg, 1500mg, and 2000mg of chlorobenzene as enrichment medium to five 1L inorganic salt medium respectively, wherein the inorganic salt medium includes a mass ratio of 3:1:1.5:0.1:0.03:0.005 :K of 0.01 2 HPO 4 、KH 2 PO 4 , NH 4 Cl, MgSO 4 , MnSO 4 , FeSO 4 ·7H 2 O and CaCl 2 2H 2 O, and chlorobenzene was added therein so that the mass ratio of carbon, nitrogen, and phosphorus in the medium was 90:3:1; respectively, 1 mL of the enriched culture solution in the above-mentioned enriched medium was applied to the inorganic salt medium And add the bacterial strain isolated from the biofilm on the surface of the biotrickling filter packing, culture at 30°C for 1d, pick the grown colony into a 96-well plate equipped with 100μL inorganic salt medium, cultivate it for 0.5d, and use A 4mm sterile filter paper sheet absorbs the culture solution and pastes it on the identification medium. The identification medium is formed by adding 1500mg chlorobenz...

Embodiment 2

[0040] Add 250mg, 500mg, 1000mg, 1500mg, and 2000mg of chlorobenzene as enrichment medium to five 1L inorganic salt medium respectively, wherein the inorganic salt medium includes a mass ratio of 5:3:3:0.3:0.08:0.015 :K of 0.05 2 HPO 4 、KH 2 PO 4 , NH 4 Cl, MgSO 4 , MnSO 4 , FeSO 4 ·7H 2 O and CaCl 2 2H 2 O, and chlorobenzene was added therein so that the mass ratio of carbon, nitrogen, and phosphorus in the medium was 110:7:1; respectively, 1 mL of the enriched culture solution in the above-mentioned enriched medium was applied to the inorganic salt medium And add the strain isolated from the biofilm on the surface of the biotrickling filter packing, culture at 45°C for 5 days, pick the grown colony into a 96-well plate with 200 μL of inorganic salt medium, cultivate it for 3 days, and then use 8mm After absorbing the culture solution, paste it on the identification medium. The identification medium is formed by adding 2500mg chlorobenzene and 20g agar to 1L inorgan...

Embodiment 3

[0045] Add 250mg, 500mg, 1000mg, 1500mg, and 2000mg of chlorobenzene to five 1L inorganic salt mediums as enrichment medium, wherein the inorganic salt medium includes a mass ratio of 4:2:2.2:0.2:0.05:0.01 :K of 0.03 2 HPO 4 、KH 2 PO 4 , NH 4 Cl, MgSO 4 , MnSO 4 , FeSO 4 ·7H 2 O and CaCl 2 2H 2 O, and chlorobenzene was added therein so that the mass ratio of carbon, nitrogen, and phosphorus in the medium was 100:5:1; respectively, 1 mL of the enriched culture solution in the above-mentioned enriched medium was applied to the inorganic salt medium And add the bacterial strain isolated from the biofilm on the surface of the biotrickling filter packing, culture at 37°C for 3 days, pick the grown colony into a 96-well plate containing 150 μL of inorganic salt medium, cultivate it for 1.7 days, and use A 6mm sterile filter paper sheet absorbs the culture solution and pastes it on the identification medium, which is formed by adding 2000mg chlorobenzene and 15g agar to 1L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com