Treating and recycling method of sodium hypochlorite-containing waste liquid

A technology of sodium hypochlorite and waste liquid, which is applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. Effectiveness of utilization, cost saving in wastewater treatment, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

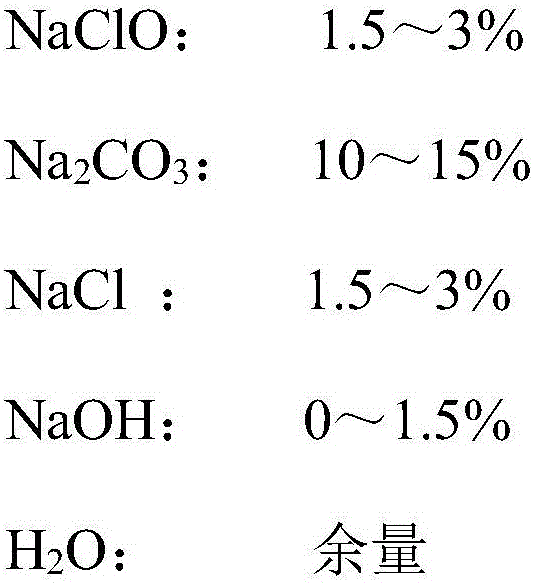

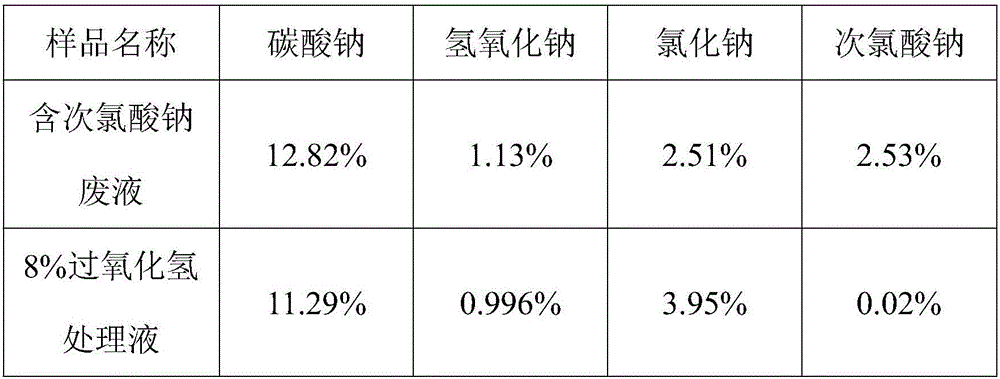

[0026] (1) The sodium hypochlorite waste liquid (concrete composition and content see Table 1) that hydrogen chloride catalytic oxidation system chlorine plant produces is sent into absorption tower from the top with the flow rate of 1000kg / h, simultaneously with the hydrogen peroxide solution of mass percent 8% Send it into the absorption tower from the top at a flow rate of 114.3kg / h;

[0027] The waste liquid containing sodium hypochlorite and hydrogen peroxide are in the absorption tower. After rapid reaction, they flow into the bottom of the absorption tower. Excessive hydrogen peroxide is completely decomposed, and the treatment liquid is obtained from the absorption tower kettle, and the components and contents are shown in Table 1;

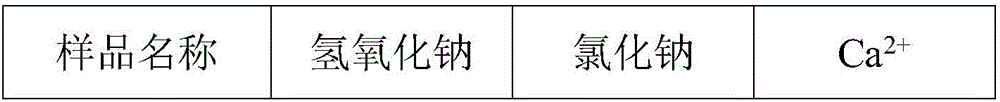

[0028] (2) 1408kg of treatment liquid is delivered to the post-reactor of the primary brine section with a pump, and reacts with 150000kg of crude brine (see Table 2 for specific components and content) to generate calcium carbonate precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com