Preparation method of jettisonable aptamer sensor for OTA sensitivity detection

An aptamer sensor and sensitive detection technology, which is applied in the field of electrochemical detection, can solve the problems of troublesome and time-consuming processing steps, cumbersome operation steps, and high detection cost, and achieve the advantages of avoiding pretreatment procedures, simple and flexible operation, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Nano Colloidal Gold Solution Modified by MPA

[0032] (1) Take HAuCl with a mass concentration of 0.01% 4 Solution 100mL, heated to boiling, mass concentration 1% trisodium citrate solution 3mL was added rapidly under stirring condition, and continued to boil for about 15 minutes. After the reaction was completed, the solution was cooled to room temperature, and 10 mL of the colloidal gold prepared above was taken, and 60 μL of MPA was added dropwise with a pipette while shaking, and the shaking was continued for 5 hours after the dropwise addition was completed. After the reaction, the colloid was centrifuged at 13000rpm for 10min to obtain a purple-black precipitate. After washing with water for 3 times, 5mL of 50mM Tris-HCl buffer solution (pH 7.4) was added to the purple-black precipitate, and the precipitate was immediately uniformly dispersed into a purple-red colloidal solution. , which are AuNPs protected by MPA.

[0033] Preparation of PDDA-mod...

Embodiment 2

[0038] Construction of electrochemical aptasensors

[0039] (4) Preparation of gold nanoparticle-modified screen-printed electrode (Au NPs-SPCE): 10 μL of the MPA-modified colloidal gold solution prepared in step (1) was drip-coated on the surface of the screen-printed electrode prepared in step (3), React at room temperature for 2 hours, and seal and store at 4°C for later use.

[0040] (5) Preparation of aptamer-modified Au NPs-SPCE electrode: First, take 10 μL of 100 μM OTA aptamer standard droplet and apply it on the surface of the working electrode prepared in step (4), react at room temperature for 12 hours, and use Rinse with 50mM Tris-HCl buffer solution (pH 7.4), blow dry with nitrogen; then immerse the electrode in 5mL 1mM 6-mercaptohexanol (MCH), react at room temperature for 1 hour, seal the electrode and buffer with Tris-HCl rinse with liquid, blow dry with nitrogen, and store in a sealed container at 4°C for later use.

Embodiment 4

[0042] Establishment of standard curve for ochratoxin (OTA) detection

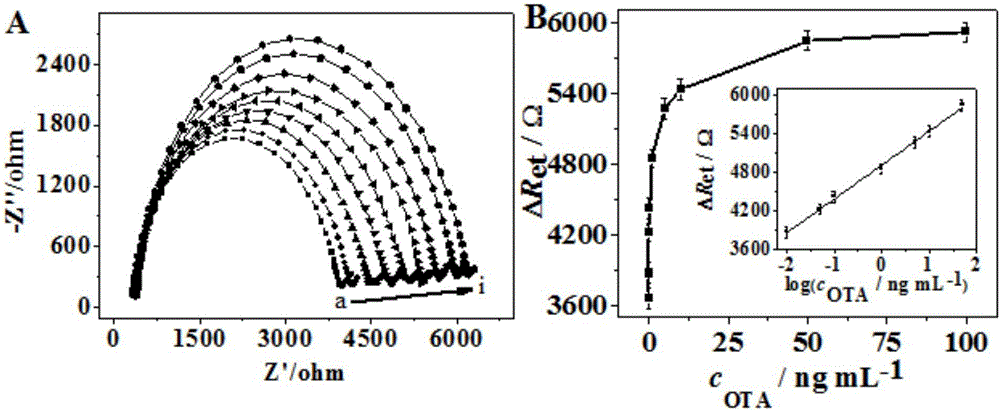

[0043] (6) Detect the OTA standard and establish a standard curve: drip-coat the OTA standard on the electrochemical sensing interface prepared in step (5), incubate at 37°C for 30 minutes, and then use 50mM Tris-HCl Rinse with buffer solution (pH 7.4), dry with nitrogen gas; finally place the electrode in impedance solution, scan electrochemical impedance spectroscopy (EIS), and establish a standard curve based on the impedance value and the corresponding OTA standard concentration. figure 1 Among them, Figure A is at different OTA concentrations (from a to i are: 0, 0.01, 0.05, 0.1, 0.05, 0.1, 5, 10, 50, 100ng mL -1 ), it can be seen from the figure that with the increase of the concentration, the semicircular arc presented in the impedance spectrum gradually increases, indicating that the addition of OTA has a significant hindrance to the charge transfer in the sensing system ; Figure B is the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com