Preparation method of mica film and transistor

A technology of transistors and mica, which is applied in the preparation method of mica thin films and the field of transistors, can solve the problems of deterioration of key performances such as breakdown voltage, efficiency, and gain of devices, affect the stability and reliability of device performance, and cannot completely prevent the impact, etc., to achieve The effect of suppressing current collapse, reducing process complexity, and reducing gate current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

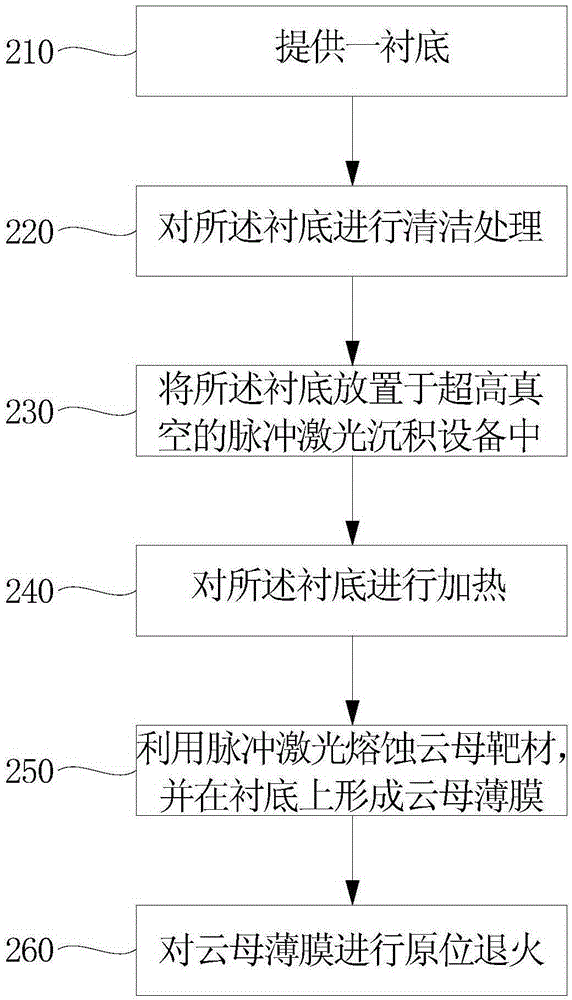

[0018] In order to better illustrate the technical means adopted by the present invention and its effects, a detailed description will be given below in conjunction with the embodiments of the present invention and the accompanying drawings. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

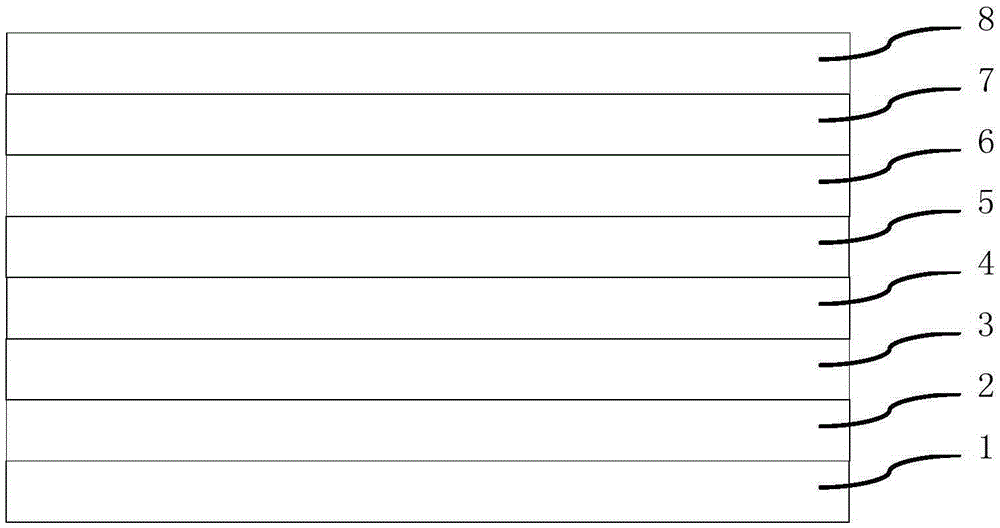

[0019] figure 1 is a schematic diagram of a GaN-based high electron mobility transistor according to an embodiment of the present invention.

[0020] refer to figure 1 As shown, the gallium nitride-based high electron mobility transistor according to the embodiment of the present invention includes a substrate 1, a buffer layer 2 on the substrate 1, a gallium nitride high resistance layer 3 on the buffer layer 2, a nitrogen The gallium nitride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com