Magnesium hydroxide flame retardant agent processing pocess

A processing technology, magnesium hydroxide technology, applied in dyeing organosilicon compound treatment, dyeing low-molecular organic compound treatment, dyeing physical treatment, etc., can solve the problem that the particle size of magnesium hydroxide flame retardant is difficult to meet the requirements, waste of water resources, Environmental pollution and other problems, to achieve the effect of small hardness, reduced pollution, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

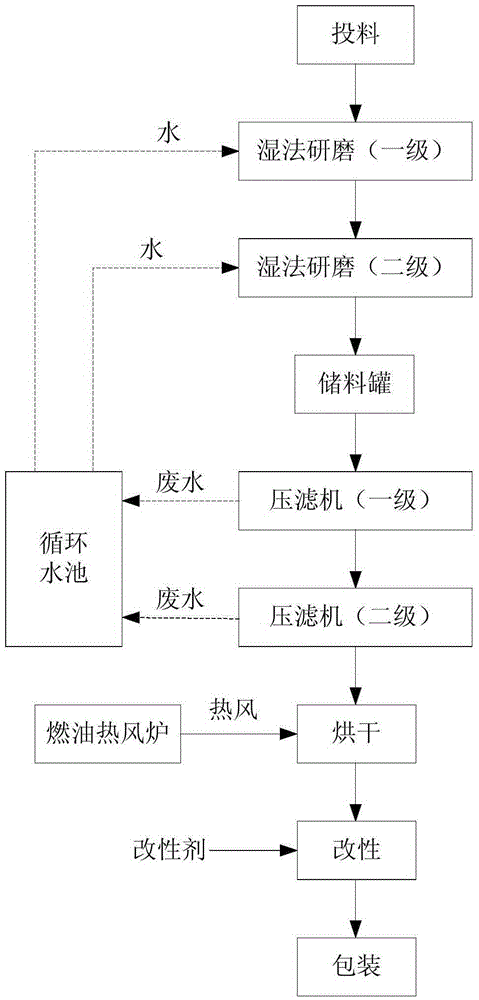

[0018] During specific implementation, combined with figure 1 Processing flow chart.

[0019] A processing technology of magnesium hydroxide flame retardant, comprising the following steps:

[0020] 1) Feeding: Select 325-mesh brucite powder and add it to the feeding bin.

[0021] 2) Wet grinding: raw materials are automatically added from the feeding bin to the wet mixing mill for grinding. Due to the different uses of the products, the product fineness is 2000 mesh, 3500 mesh, 6000 mesh, etc. According to the different requirements of product fineness, the product adopts secondary grinding process. When the fineness is less than 3000 mesh, the primary grinding process is adopted; when the product fineness is required to be above 3000 mesh, the brucite slurry is ground by the secondary grinding process and pumped into the storage tank.

[0022] 3) Pressure filtration: The brucite slurry stored in the storage tank is pumped into two filter presses for graded pressure filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com