Water-soluble glabridin microcapsule and preparation method thereof

A glabridin, water-soluble technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve problems such as poor stability of water-soluble glabridin capsules, and achieve protection of structural integrity and stability, spherical shape The effect of improving the active utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

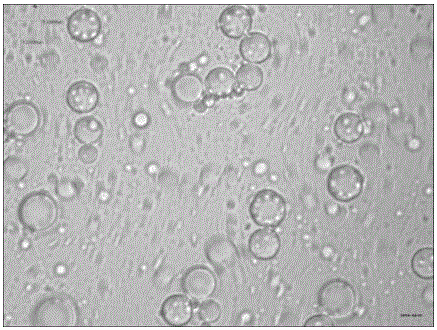

Image

Examples

Embodiment 1

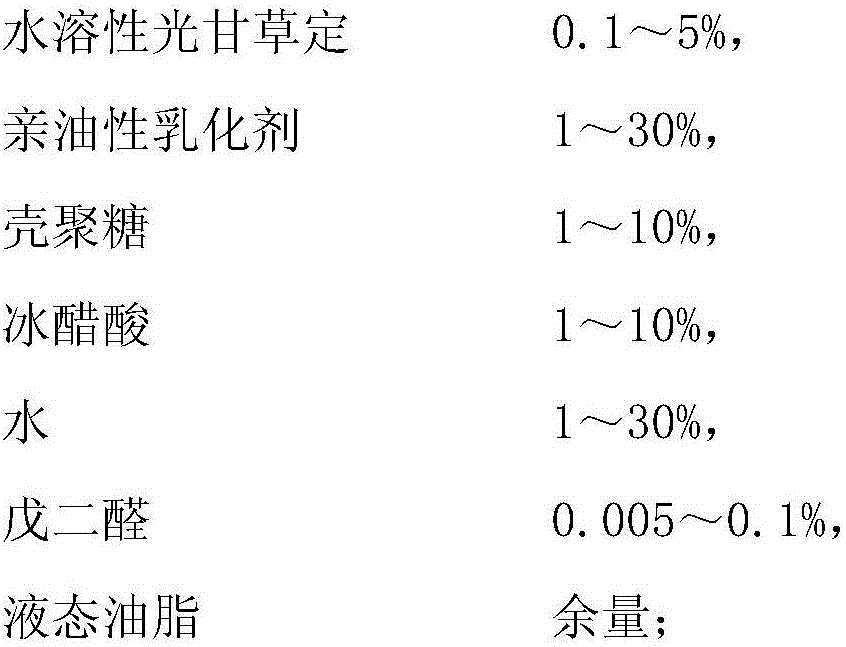

[0046] Based on 1000g of formulation raw materials, take 1g of water-soluble glabridin, 10g of lipophilic emulsifier, 10g of chitosan, 10g of glacial acetic acid, 10g of water, 0.05g of glutaraldehyde, and 958.95g of liquid oil.

[0047] Described lipophilic emulsifier is ceteareth-6;

[0048] The liquid oil is caprylic capric triglyceride;

[0049] The steps of preparation method are as follows:

[0050] 1) glacial acetic acid is dissolved in water to make acetic acid solution;

[0051]2) Chitosan is added to the acetic acid solution prepared in step 1), heated at 30° C. to dissolve completely, and the chitosan acetic acid solution is obtained after standing to remove air bubbles;

[0052] 3) adding water-soluble glabridin into the solution prepared in step 2), and stirring evenly at 25°C to obtain the first solution;

[0053] 4) Add the lipophilic emulsifier into the liquid oil, and stir evenly in a constant temperature water bath at 25°C to obtain the second solution;

...

Embodiment 1

[0058] Embodiment 1 comparative example:

[0059] That is, a 1% water-soluble glabridin aqueous solution is prepared.

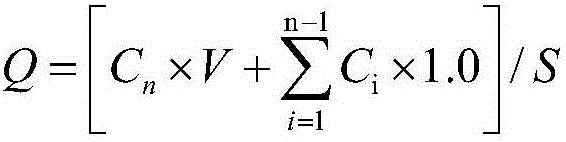

[0060] The water-soluble glabridin microcapsules obtained in the above-mentioned Example 1 and the obtained comparative example of Example 1 contain 1% water-soluble glabridin aqueous solution permeability data determination, and the results are shown in the following table:

[0061]

Embodiment 2

[0063] Based on 1000g of formula raw materials, take 50g of water-soluble glabridin, 300g of lipophilic emulsifier, 100g of chitosan, 100g of glacial acetic acid, 300g of water, 1g of glutaraldehyde, and 149g of liquid oil.

[0064] Described lipophilic emulsifier is ceteareth-25;

[0065] Described liquid grease is isopropyl myristate;

[0066] The steps of preparation method are as follows:

[0067] 1) glacial acetic acid is dissolved in water to make acetic acid solution;

[0068] 2) Chitosan is added to the acetic acid solution prepared in step 1), heated at 60° C. to completely dissolve, and the chitosan acetic acid solution is obtained after standing to remove air bubbles;

[0069] 3) adding water-soluble glabridin to the solution prepared in step 2), stirring at 50°C to obtain the first solution;

[0070] 4) Add the lipophilic emulsifier into the liquid oil, and stir evenly in a constant temperature water bath at 60°C to obtain the second solution;

[0071] 5) Heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com