Ru-Ti-AC catalytic material and a preparation method thereof

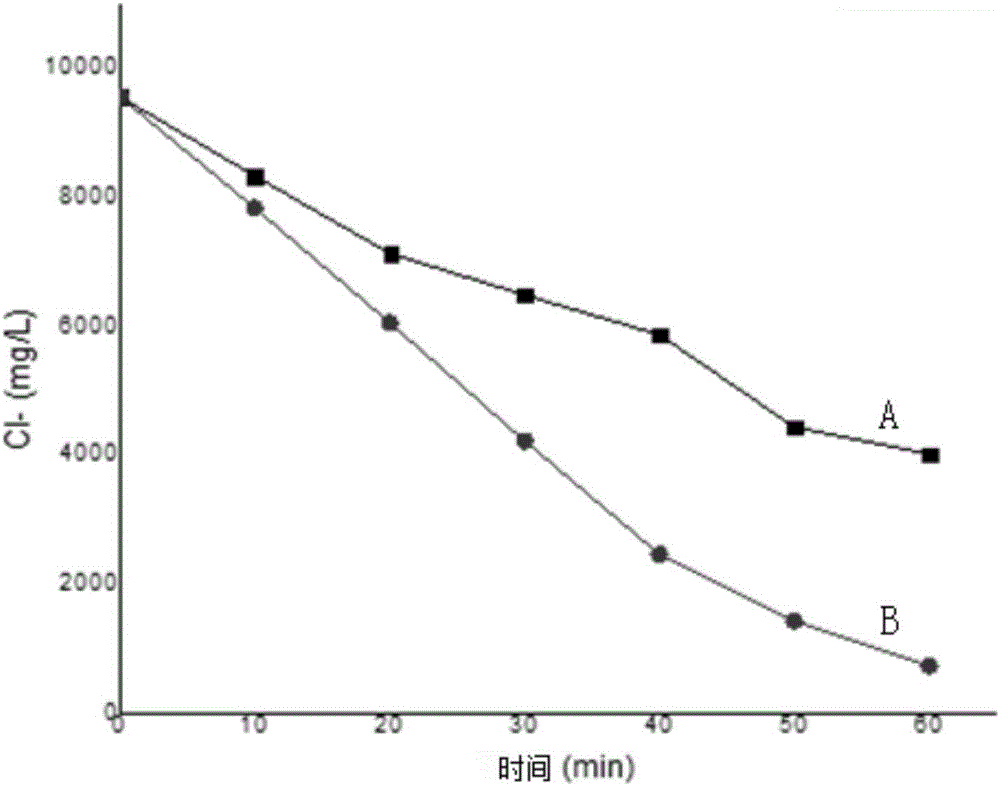

A catalytic material, ru-ti-ac technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the limitations of large-scale application, impact, electrical Long adsorption time and other problems, to achieve the effect of large-scale industrial application, high chloride ion degradation rate, high electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] An embodiment of the present invention provides a method for preparing a Ru-Ti-AC catalytic material, which includes the following steps:

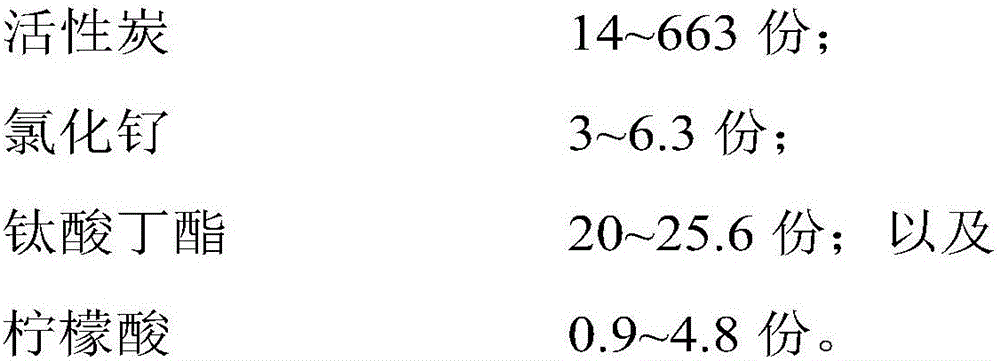

[0035] S1. In parts by weight, 14 to 663 parts of activated carbon are soaked in an acidic aqueous solution for 40 to 45 hours. The preferred particle size of the activated carbon is 5 to 100 mesh, and the acidic aqueous solution is preferably a phosphoric acid aqueous solution with a mass concentration of 15% to 50%. Filter the filter cake; wash the filter cake with deionized water until the pH value is 6.5-8.5, preferably until the washing liquid after washing is neutral; place the washed filter cake in a drying oven at 60-90°C for drying Dry, obtain pretreated activated carbon, and set aside.

[0036] S2. Mix pretreated activated carbon with solvent, 3 to 6.3 parts of ruthenium chloride, 20 to 25.6 parts of butyl titanate, and 0.9 to 4.8 parts of citric acid, and stir evenly to obtain a mixed reaction solution, wherein the ruthen...

Embodiment 1

[0056] This embodiment provides a Ru-Ti-AC catalytic material, which is prepared according to the following method:

[0057] S101, soak the activated carbon with a particle size of 30 meshes in 40% phosphoric acid aqueous solution for 40 hours, and filter the filter cake; wash the filter cake with deionized water until the pH value of the washing solution after washing is 7; The filter cake was dried in a drying oven at 90°C to obtain pretreated activated carbon for later use.

[0058] S102, take 20g pretreated activated carbon, 40ml butanol, 2gRuCl 3` nH 2 O (as 100% RuCl 3 ), 7.6ml butyl titanate and 2.304g (40ml 0.3M) citric acid were mixed, stirred evenly to obtain a mixed reaction solution, then in the mixed reaction solution, hydrazine hydrate was added dropwise to adjust the pH value of the mixed reaction solution 6.5; then react in a water bath at 92°C for 0.8h to form a viscous slurry.

[0059] S103. The slurry was evaporated to dryness in a constant temperature o...

Embodiment 2

[0066] This embodiment provides a Ru-Ti-AC catalytic material, which is prepared according to the following method:

[0067] S201. Soak the activated carbon with a particle size of 5 mesh in 15% phosphoric acid aqueous solution for 45 hours, and filter the filter cake; wash the filter cake with deionized water until the pH value of the washing solution after washing is 6.5; wash the filter cake The filter cake was dried in a drying oven at 90°C to obtain pretreated activated carbon for later use.

[0068] S202, take 20g pretreated activated carbon, 40ml butanol, 2gRuCl 3` nH 2 O (as 100% RuCl 3 ), 7.6ml butyl titanate and 2.304g (40ml 0.3M) citric acid were mixed, stirred evenly to obtain a mixed reaction solution, then in the mixed reaction solution, hydrazine hydrate was added dropwise to adjust the pH value of the mixed reaction solution 7; react in a water bath at 95°C for 0.8h to form a viscous slurry.

[0069] S203. The slurry was evaporated to dryness in a constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com