Cycloalkane dehydrogenation catalyst, preparation method thereof and application

A dehydrogenation catalyst and naphthenic technology, which are applied in the field of chemical hydrogen storage, can solve the problems of difficulty in controlling dispersion, the limitation of carrier acidity regulation, etc., and achieve the effects of promoting dispersion, simple preparation process, excellent catalytic reaction activity and hydrogen production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

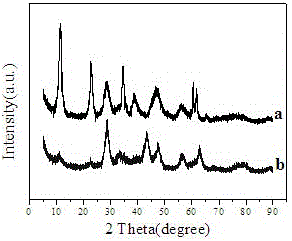

Image

Examples

Embodiment 1

[0027] Weigh 1.88g of aluminum nitrate, then press Al 3+ / Mg 2+ / C 3+ The molar ratio is 5:15:1. Measure and weigh a certain amount of magnesium nitrate and cerium nitrate and dissolve them in 40 mL of deionized water to prepare metal salt mixed solution A; weigh 2.40 g of NaOH and 0.4 g of anhydrous Na 2 CO 3 Dissolve in 50 mL of deionized water to make alkali mixed solution B. Under room temperature and vigorous stirring, use a constant pressure titration funnel to drop the alkali mixed solution B into the three-necked flask containing the metal salt mixed solution A at a speed of 4 mL / min, and control the pH value of the suspension in the three-necked flask at 9.5~ Within the range of 10.5, stop adding the alkali mixed solution B dropwise, continue the reaction for 30 minutes, transfer the suspension to a hydrothermal reaction kettle, crystallize at 95ºC for 10 hours, then suction filter the suspension, and wash the filtered solid , drying to obtain Ce-Mg-Al hydrotalcit...

Embodiment 2

[0030]According to the preparation process and activity test conditions of the catalyst in Example 1, only the dehydrogenation reaction temperature was adjusted to 325°C to catalyze the dehydrogenation of methylcyclohexane, and the dehydrogenation conversion rate of the catalyst was 99.1% during the continuous reaction for 8 hours. The hydrogen production rate is 139 mmolH 2 g -1 cat. h -1 .

Embodiment 3

[0032] According to the preparation process and activity test conditions of the catalyst in Example 1, only the dehydrogenation reaction temperature was adjusted to 325°C to catalyze the dehydrogenation of cyclohexane, and the dehydrogenation conversion rate of the catalyst was 99.3% during the continuous reaction for 8 hours, and hydrogen production rate of 139 mmol H 2 g -1 cat. h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com