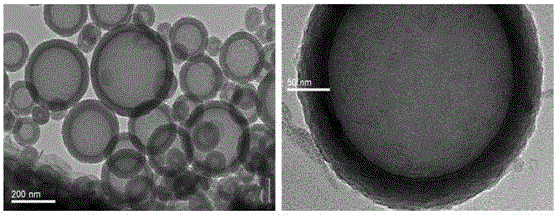

Method for preparing cellulose supported hollow SiO2 microsphere catalytic carrier

A catalytic carrier and cellulose technology, applied in the field of material engineering, can solve the problems of cumbersome preparation steps, time-consuming, and uneven particle size of hollow microspheres, and achieve high application value, increase adsorption, and improve preparation steps. time consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

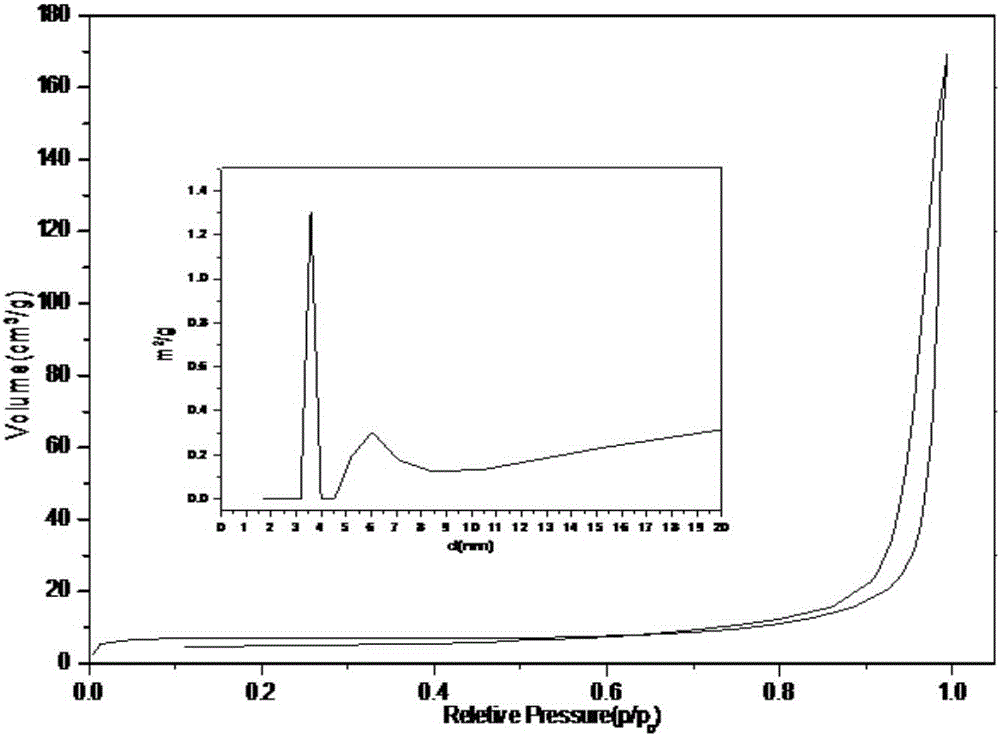

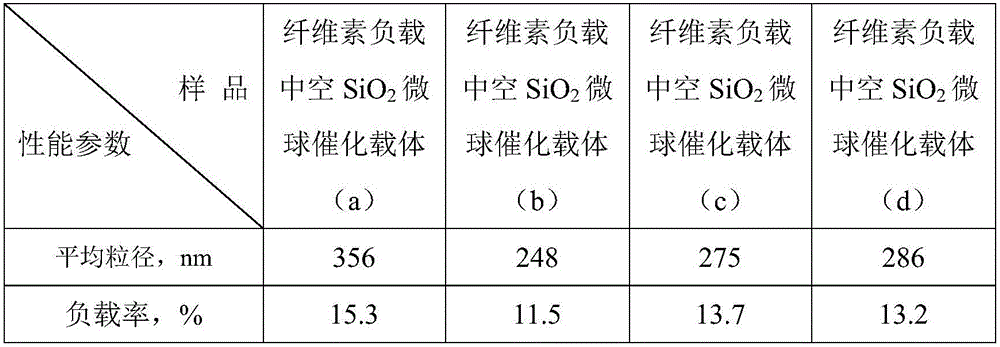

[0020] 1) Place 0.1 g of polyacrylic acid in a conical flask, and at room temperature, add 2 mL of ammonia with a concentration of 25% to dissolve the polyacrylic acid into a transparent and clear solution, stir and quickly pour 25 mL of 99.7% ethanol into it, The solution turned milky white, and then 0.5 mL of tetraethyl orthosilicate was injected into the reaction solution in 4 times at intervals of 2 hours each time. Continue stirring for 5 h, centrifuge and wash with distilled water for 5 times and dry to obtain hollow SiO 2 Microspheres;

[0021] 2) the hollow SiO obtained in step 1) 2 Microspheres by Hollow SiO 2 The reaction mass ratio of microspheres and cyanuric chloride is 1:1, adding cyanuric chloride and reacting in ice bath for 4 hours, and then mixing rice straw cellulose powder with N,N-dimethylformamide 1:2 mass ratio dissolved in N,N-dimethylformamide, the loaded hollow SiO 2 Microspheres by Hollow SiO 2 The reaction mass ratio of microspheres to cellulos...

Embodiment 2

[0023] 1) Put 0.15g of polyacrylic acid in a conical flask, and at room temperature, add 1.5mL of 25% ammonia to dissolve the polyacrylic acid into a transparent solution, stir and quickly pour 20mL of 99.7% ethanol , the solution turned milky white, and then 0.5 mL of tetraethyl orthosilicate was injected into the reaction solution in 4 times at intervals of 3 h each time. Continue stirring for 3 h, centrifuge and wash with distilled water for 5 times and dry to obtain hollow SiO 2 Microspheres;

[0024] 2) the hollow SiO obtained in step 1) 2 Microspheres by Hollow SiO 2The reaction mass ratio of microspheres and cyanuric chloride is 2:1, adding cyanuric chloride and reacting in ice bath for 3 hours, then the straw cellulose powder is mixed with N,N-dimethylformamide 3:2 mass ratio dissolved in N,N-dimethylformamide, the loaded hollow SiO 2 Microspheres by Hollow SiO 2 The reaction mass ratio of microspheres and cellulose powder is 3:10. Add cellulose powder dissolved i...

Embodiment 3

[0026] 1) Place 0.2 g of polyacrylic acid in a conical flask, and at room temperature, add 1 mL of ammonia with a concentration of 25% to dissolve the polyacrylic acid into a transparent and clear solution, stir and quickly pour 40 mL of 99.7% ethanol into it, The solution turned milky white, and then 0.75 mL of tetraethyl orthosilicate was injected into the reaction solution in 4 times at intervals of 1 h each time. Continue stirring for 5 h, centrifuge and wash with distilled water for 5 times and dry to obtain hollow SiO 2 Microspheres;

[0027] 2) the hollow SiO obtained in step 1) 2 Microspheres by Hollow SiO 2 The reaction mass ratio of microspheres and cyanuric chloride is 3:1, adding cyanuric chloride and reacting in ice bath for 4 hours, then the bagasse cellulose powder is mixed with N,N-dimethylformamide 1:2 mass ratio dissolved in N,N-dimethylformamide, the loaded hollow SiO 2 Microspheres by Hollow SiO 2 The reaction mass ratio of microspheres to cellulose po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com