A method and device for treating waste water

A technology for treating wastewater and wastewater, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, heating water/sewage treatment, etc. To achieve the effect of realizing the scale transfer of wastewater, slowing down the scale, and increasing the heat transfer rate and heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

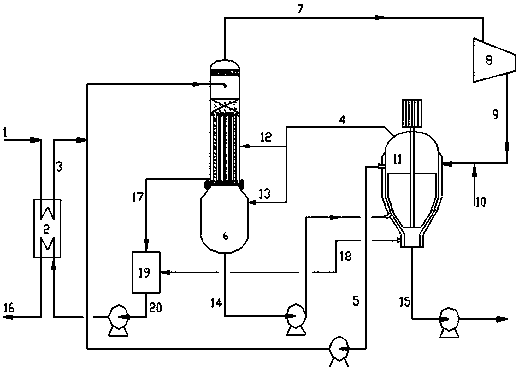

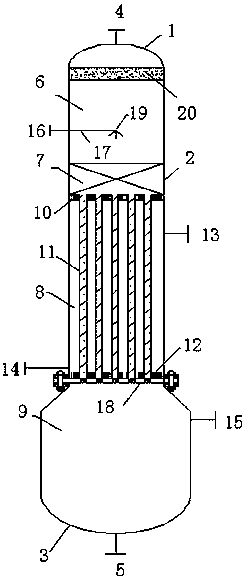

[0069] use figure 1 The device, the processor adopts figure 2 According to the device, the acrylonitrile production wastewater mainly contains acrylonitrile polymer compounds, the Kjeldahl nitrogen content in the acrylonitrile wastewater is 4050mg / L, and the evaporation boiling point of the wastewater is 100°C. When the wastewater evaporates more than 80%, the concentrated solution is easy to freeze. Dirt, coking. The raw material wastewater treatment capacity is 15t / h, and the room temperature wastewater is preheated to 99°C through the preheater 2, mixed with the 104°C concentrated liquid, and enters the evaporator 6A. The flow ratio of raw material wastewater to reflux concentrate wastewater is 3:1. The evaporation temperature of the waste water in the evaporator 6A is 104°C, the compression ratio of the steam compressor 9 is 1.5, and the volume ratio of the compressed steam as the evaporation heat source to the steam as the carrier gas is 4:1. The temperature of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com