Method for preparing Ti3SiC2/SiC/Al composite material

A technology of composite materials and raw materials, applied in the field of preparation of Ti3SiC2/SiC/Al composite materials, to achieve the effect of improving strength and toughness, simple steps, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

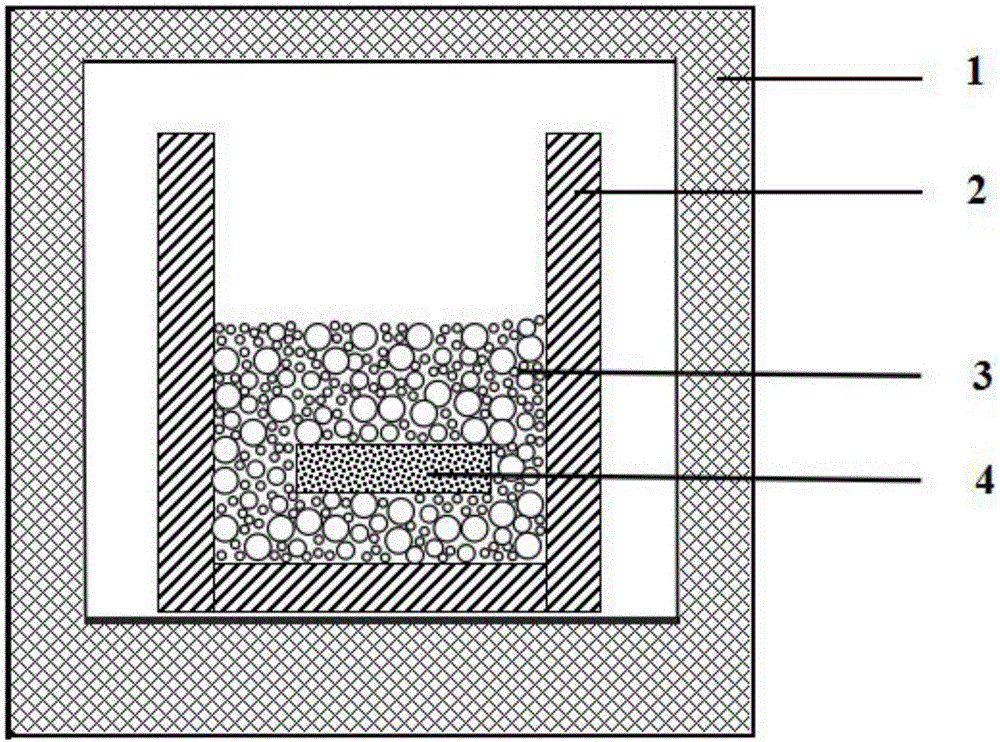

[0021] Ti of the present invention 3 SiC 2 / SiC / Al composite material preparation method, the method comprises the steps:

[0022] 1) Preparation of Al-based alloy: the mass percentage of each element of Al-based alloy is: Al, 60-80wt%; Ti, 5-20wt%; Cu, 0-10wt%; Si, 5-25wt%;

[0023] Weigh the corresponding raw materials according to the mass percentage of the above elements, place the Al ingot in a graphite crucible, and heat it until it is completely melted, then add titanium, silicon, and copper into the molten aluminum, and heat up to 800-1100 ℃, keep warm, and stir until completely dissolved, that is, the Al-based alloy liquid in molten state is obtained;

[0024] 2) Treatment of SiC ceramics: Cut the SiC ceramic raw materials into the required size with a diamond cutter; then grind the surface of the SiC ceramics with a diamond grinding disc until the surface is smooth and free of oxide layers; then use acetone and absolute ethanol in sequence Ultrasonic cleaning, and...

Embodiment 1

[0032] This embodiment Ti 3 SiC 2 The preparation method of / SiC / Al composite material is as follows:

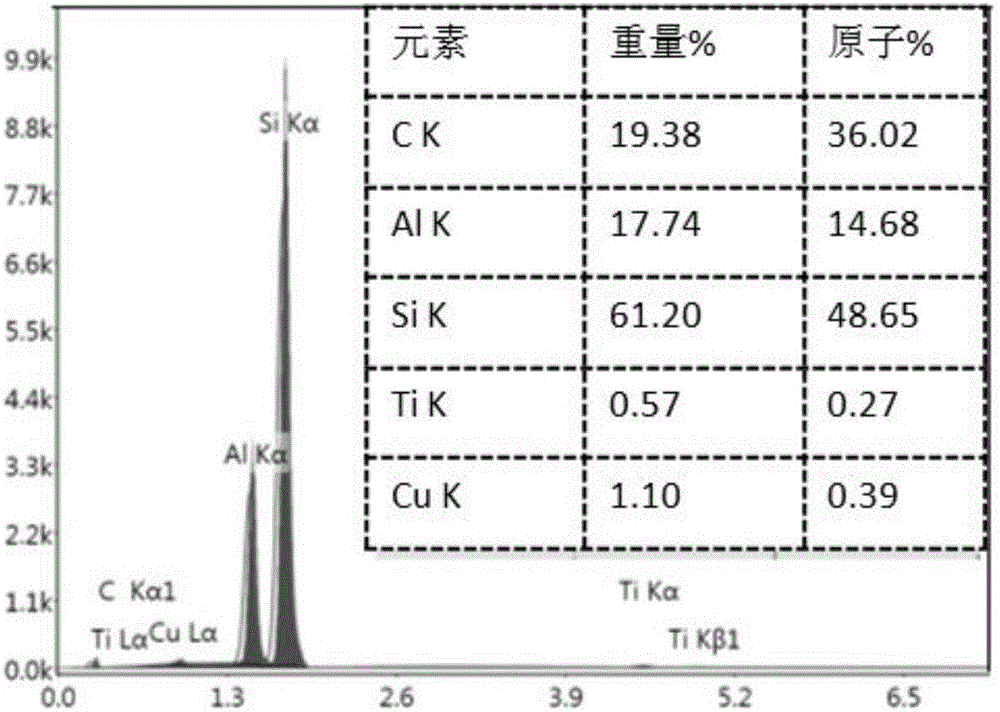

[0033] 1) Preparation of Al-based alloy: the mass percentage of each element of the Al-based alloy is composed of: Al, 70wt%; Ti, 15wt%; Cu, 5wt%; Si, 10wt%;

[0034] Weigh the corresponding raw materials according to the mass percentage of the above-mentioned elements. The raw materials are Al ingot, Ti ingot, Cu plate, and Si block respectively. Put 150g of Al ingot in a graphite crucible and heat it to 700°C in a box-type resistance furnace until it is completely melted. , then add 32gTi, 10.7g Cu, and 21.4g Si into the molten aluminum, raise the temperature to 900°C, the heating rate is 15°C / min, keep at this temperature for 60min, stir until completely dissolved, That is, the Al-based alloy liquid in a molten state is obtained;

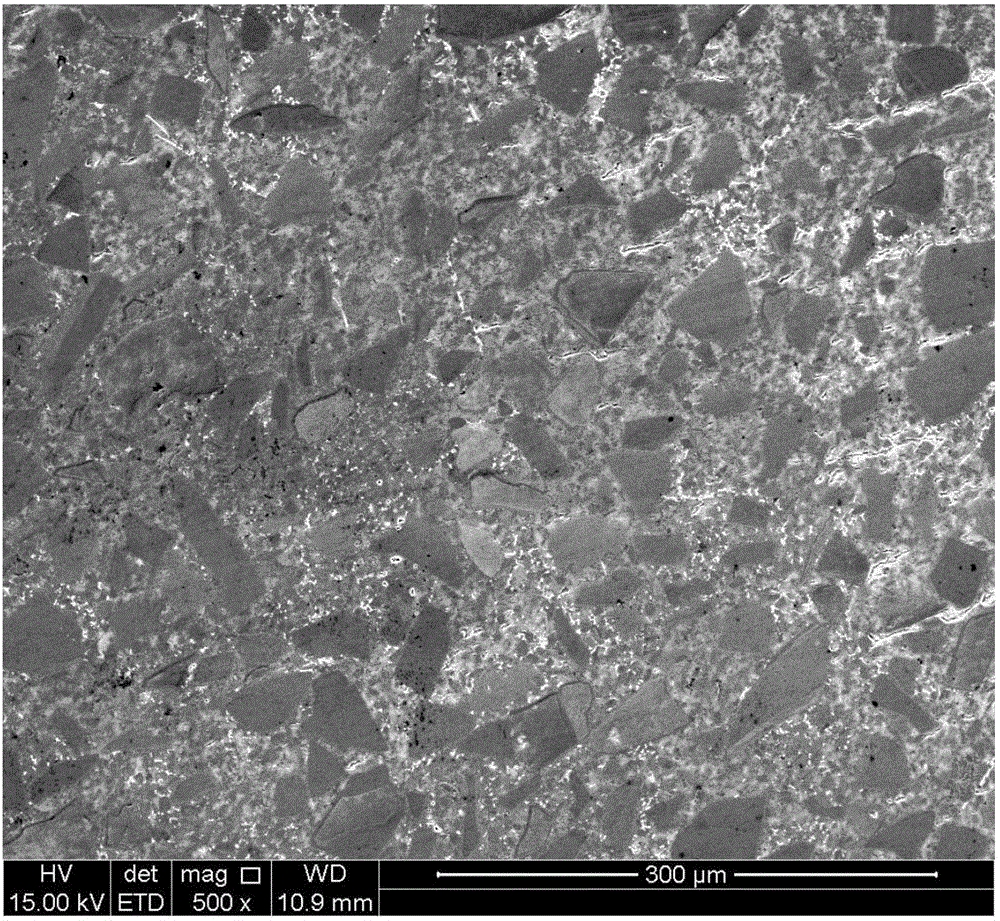

[0035] Take a small amount of the molten Al-based alloy liquid and cool it into an ingot, cut 3mm×3mm×3mm alloy particles, and test the wet...

Embodiment 2

[0044] This embodiment Ti 3 SiC 2 The specific steps of the preparation method of the / SiC / Al composite material are the same as in Example 1, except that the impregnation time of this example is 6 hours.

[0045] According to the test and analysis process of Example 1, the composite material prepared in this embodiment was analyzed and tested, and the specific results were: after the three-point bending strength test, the average bending strength of the composite material prepared in this embodiment was 413MPa, which was higher than that of the original SiC Ceramic (179MPa) increased by 234Mpa.

[0046] The surface XRD test results are as follows Figure 5 As shown, the outer layer (interface) of the composite material of this embodiment has a large amount of Ti 3 SiC 2 generated without TiC. The impregnation time is 6h, and Ti 3 SiC 2 / SiC / Al composite material, and Al can completely penetrate into SiC ceramics, due to the prolongation of impregnation time, Ti 3 SiC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average bending strength | aaaaa | aaaaa |

| Average bending strength | aaaaa | aaaaa |

| Average bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com