Method for preparing methyl carbamate by urea alcoholysis method and device thereof

A technology for methyl carbamate and a preparation device, applied in the field of synthesizing methyl carbamate, can solve the problems of increased environmental burden, phosgene is highly toxic, and chlorine is difficult to remove, and achieves reduced production cost, easy operation, and safe production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

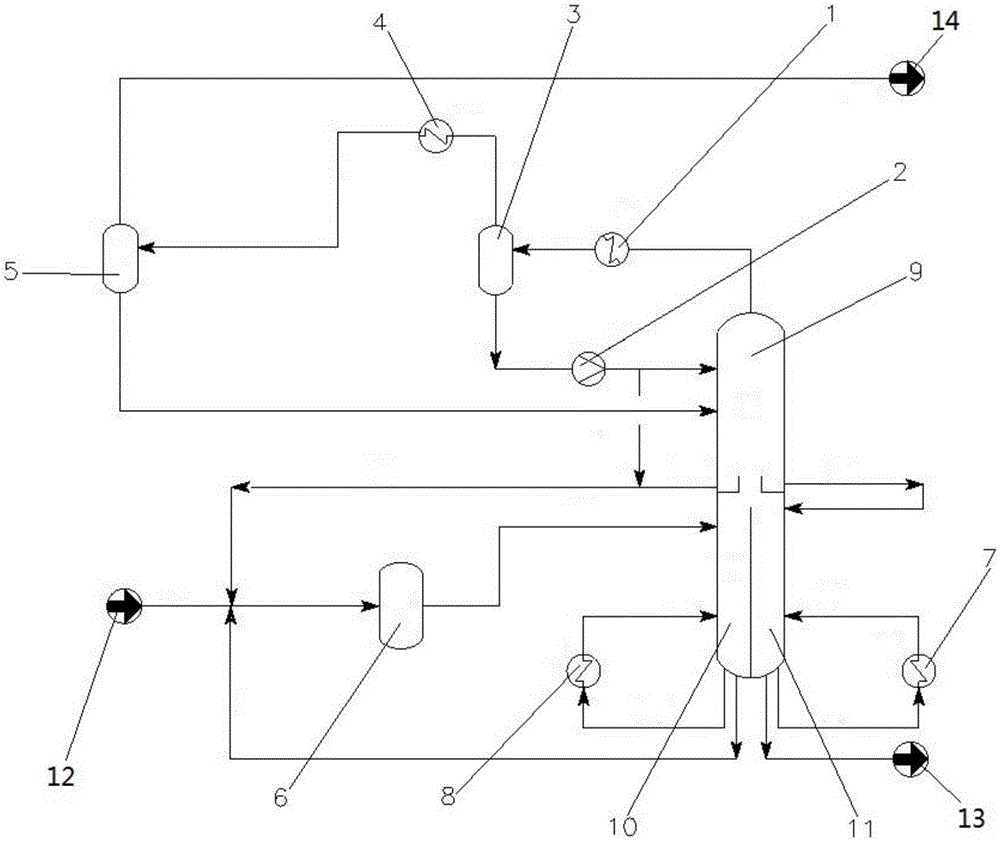

Image

Examples

preparation example Construction

[0029] The preparation process of the above catalyst includes the following steps:

[0030] Step 1. Put the silicon oxide into the hydrochloric acid solution, nitric acid solution or acetic acid solution, and then place it at 20-60℃, 0.1-0.3MPa and stir for 12-28h, and then at 120-180℃, Aging for 15-28h; a solid carrier is obtained.

[0031] Step 2: Add the active component and the auxiliary metal to the distilled water, and the solution will be obtained after stirring evenly; wherein the mass ratio of the active component and the auxiliary metal is 1:0.1-1; and the active components are Mg, Ca, Zn, At least one hydrochloride, nitrate or acetate among Fe, Cu or Pb; wherein the auxiliary metal is at least one of La, K, Sr or Ce.

[0032] Step 3. Add the solution obtained in step 2 to the solid carrier obtained in step 1, heat it to 30-80°C, stir for 8-18h; then dry it at 60-130°C for 5-10h; After calcination at -500°C for 2-8 hours, a catalyst for preparing methyl carbamate is obtai...

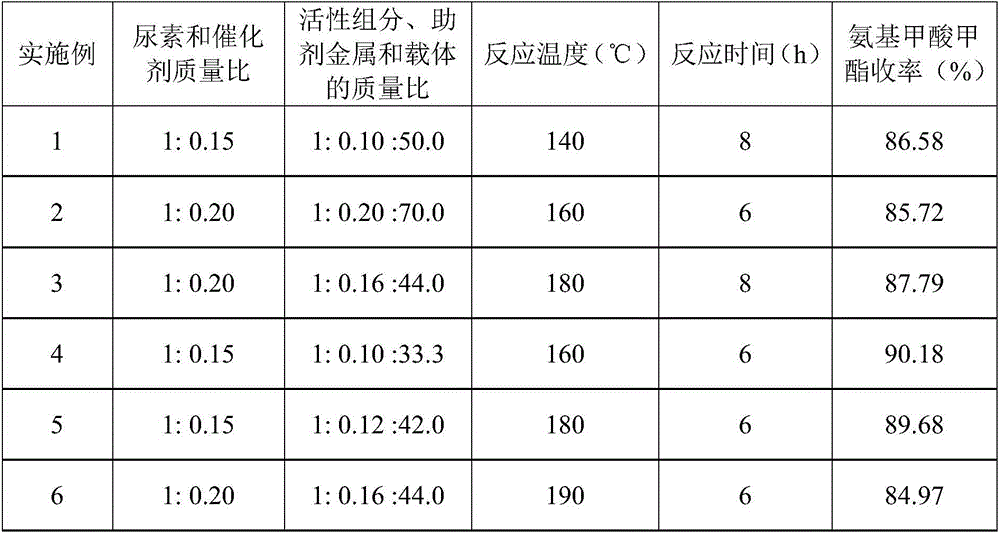

Embodiment 1

[0040] The specific process of preparing methyl carbamate is:

[0041] First prepare the catalyst: select silicon oxide for pretreatment, put the silicon oxide into the constant temperature zone of the quartz reactor, heat up to 40°C, add hydrochloric acid under normal pressure, and keep stirring for 14 hours, and then place it at 125°C. Store and age for 18 hours, and finally filter to obtain a solid carrier. Add 1.0g of Pb(C 2 H 3 O 2 ) 2 , 0.5g of ZnCl 2 , 0.5g of CaCl 2 Add 0.1g of La and 0.1g of Sr to distilled water and stir evenly to obtain a solution. The above solution was poured into 100.0 g of the treated silica carrier, and then heated to 40°C and stirred for 12 hours, then placed in an oven, dried at 80°C for 8 hours; finally, calcined at 450°C for 6 hours to obtain the catalyst.

[0042] Then weigh 10 g of urea, measure 40 mL of methanol, put it into the reaction kettle, and add 1.5 g of the above-mentioned catalyst, and heat rapidly from room temperature to 140° C. ...

Embodiment 2

[0044] The specific process of preparing methyl carbamate is:

[0045] First prepare the catalyst: select silicon oxide for pretreatment, put the silicon oxide into the constant temperature zone of the quartz reactor, heat up to 40°C, add acetic acid under normal pressure, keep stirring for 12 hours, and then place it at 120°C. Store and age for 16 hours, and finally filter to obtain a solid carrier. Add 0.5g of Pb(NO 3 ) 2 , 0.5g of ZnCl 2 , 0.5g of CuCl 2 Add 0.1 g of La and 0.2 g of Ce into distilled water and stir evenly to obtain a solution. The above solution was poured into 105.0 g of the treated silica support, and then heated to 40°C and stirred for 10 hours, then placed in an oven, dried at 80°C for 6 hours; finally, calcined at 400°C for 5 hours to obtain the catalyst.

[0046] Then weigh 10 g of urea, measure 40 mL of methanol, put it into the reactor, and add 2.0 g of the above-mentioned catalyst. Under magnetic stirring, it will be rapidly heated from room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com