Carbon-black-filled polyimide-based compound aerogel material and preparation method thereof

A composite airgel and polyimide-based technology, applied in the field of composite airgel, can solve the problems of high price and limited use of crosslinking agents, and achieve low raw material cost, low heat resistance, and microscopic morphology uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] by N,N -Dimethylacetamide is used as a solvent, and 4,4'-diaminodiphenyl ether and pyromellitic anhydride are used as monomers to carry out condensation polymerization in an ice-water bath to prepare polyamic acid filaments. The specific process is as follows: at room temperature, 8 g (0.04 mol) of 4,4′-diaminodiphenyl ether was fully dissolved in 95 g N,N -Dimethylacetamide, based on the clarity of the solution and the absence of particles. Then 8.85 g (0.046 mol) pyromellitic anhydride was added slowly, and then the reaction was moved to an ice-water bath and stirred for 2 h. Then add 0.04 mol triethylamine, continue to stir and react for about 2 h, and prepare a polyamic acid solution with a solid content of 15%. The prepared polyamic acid solution is sealed and stored, and after standing for two days, it is slowly poured into ice water, washed, frozen, and dried to obtain a water-soluble polyamic acid filam...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] The steps for preparing water-soluble polyamic acid are the same as in Example 1.

[0045] The steps of preparing oxidized carbon black are as follows:

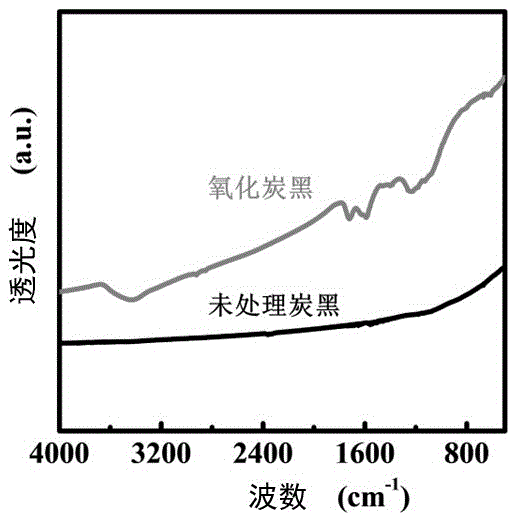

[0046] Acetylene black (specific surface area 75 m 2 / g, apparent density 90-120 g / L) as an example to prepare oxidized carbon black. Add 5 g of carbon black to a 1000 mL beaker, add 3.75 g of sodium nitrate, and stir for 10 min; then add 150 mL of concentrated sulfuric acid, and stir for 0.5 h; slowly add 20 g of potassium permanganate, after 0.5 h, stir for 20 h ; Slowly add 500 mL of deionized water, add 50 mL of 30% hydrogen peroxide after cooling, and stir for 1 h; filter the mixture with suction and wash with 10% hydrochloric acid until no sulfate ion is detected to obtain oxidized carbon black Wet filter cake; then dried at 70°C for 5 h to obtain oxidized carbon black solid.

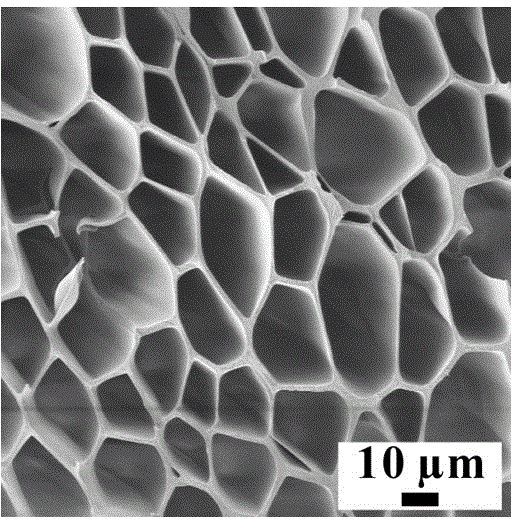

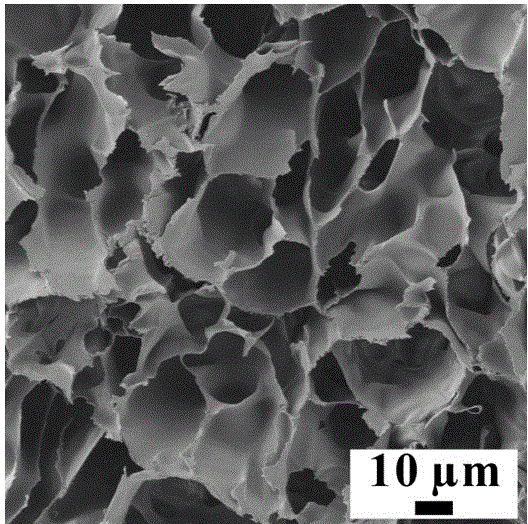

[0047] The steps of preparing polyimide-carbon black composite airgel are as f...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] The steps for preparing water-soluble polyamic acid are the same as in Example 1, and the steps for preparing oxidized carbon black are the same as in Example 2.

[0052] The steps of preparing polyimide-carbon black composite airgel are as follows:

[0053] Take 80 mg of oxidized carbon black and add it into 30 mL of deionized water, and sonicate for 0.5 h to make the oxidized carbon black disperse evenly. All the other are with embodiment 3. Obtain polyimide-carbon black composite airgel, denoted as PI / CB 4% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com