Cryogenic separation system for separating mixed gas

A technology of cryogenic separation and mixed gas, applied in cold treatment separation, educts, refrigeration and liquefaction, etc., can solve the problems of poor operation adaptability, high process energy consumption, large equipment investment, etc. , High separation efficiency, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

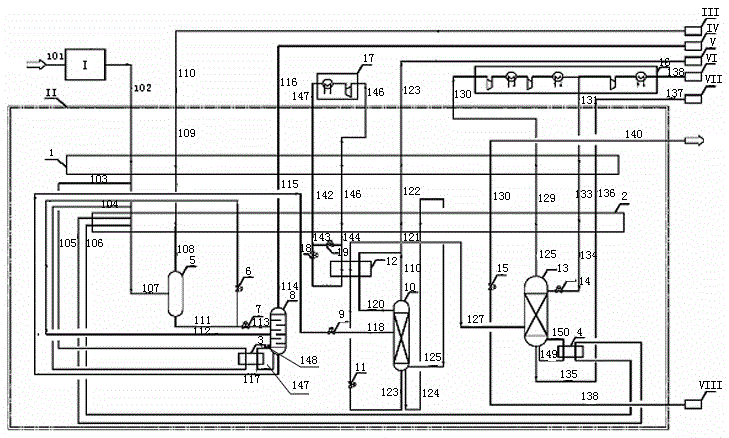

[0031] Example: figure 1 As shown, the present invention is used to separate the cryogenic separation device and method for the mixed gas containing carbon monoxide, hydrogen, methane and a small amount of nitrogen, including molecular sieve purification unit I and cryogenic separation cold box II for removing impurity gases, the deep cryogenic separation The cold separation cold box II includes the first main heat exchanger 1, the second main heat exchanger 2, the hydrogen separation tank 5, the stripping tower 8 and the set reboiler 3, the denitrification tower 10 and the set condenser 12, The demethanizer 13 and the set reboiler 4 , the nitrogen refrigeration circulation system 17 , 141 - 146 and the liquid nitrogen channels 138 , 139 , 140 . Contains carbon monoxide (30%~90%), hydrogen (70%~10%), methane, a small amount of nitrogen (≤3%) and trace CO 2 Mixed gas with methanol (pressure: 2.0MPaG~8.0MPaG) enters molecular sieve purification unit I through pipeline 101 to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com