Preparation method of porous SiOx core-shell microspheres

A technology of core-shell and microspheres, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of complex operation, high cost, and unsuitability for industrialization, and achieve volume effect relief, high carbon content, and wide application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of porous SiO core-shell microspheres, comprising the following steps:

[0028] (1) Prepare 100 parts of HF solution with a mass fraction of 1wt%-10wt% by mass, and start stirring;

[0029] (2) Slowly add 15 parts of the disproportionated SiO sample into the HF solution, stir for 0.5-2h, filter and wash, and vacuum dry to obtain porous SiOx, the SiO in the disproportionated SiO sample 2 The content is 10%-25%;

[0030] (3) Ultrasonic disperse the obtained porous SiOx and epoxy resin for 10-30 min, then dilute with 5-15 parts of chloroform, and then add 8-10 parts of curing agent to prepare a mixture. The curing agent is diethylaminopropylamine, 3 , 9-bis(3-aminopropyl)-2,4,8,10-tetraoxa spiroundecane adduct, diaminodiphenylmethane, 650 low molecular weight polyamide, triethylenetetramine A sort of;

[0031] (4) Slowly add the above mixture into the aqueous solution in which the surfactant is dissolved, stir and react at 40-60°C for 3-6h, then fil...

Embodiment 1

[0033] A preparation method of porous SiO core-shell microspheres, comprising the following steps:

[0034] (1) Preparation of porous SiOx

[0035] Configure 100 g of HF solution with a mass fraction of 5 wt%, and start stirring; slowly add 15 g of disproportionated SiO samples into the HF solution, stir for 1 h, filter and wash, and vacuum dry to obtain porous SiOx;

[0036] (2) Preparation of porous SiOx core-shell microspheres coated with epoxy resin

[0037] The obtained porous SiOx was ultrasonically dispersed with epoxy resin for 20 min, diluted with 10 g of chloroform, and 10 g of curing agent diethylaminopropylamine was added; the mixture was slowly added to an aqueous solution in which surfactant was dissolved, stirred and reacted at 60°C for 6 h, filtered and washed and vacuum drying to obtain porous SiOx core-shell microspheres coated with epoxy resin.

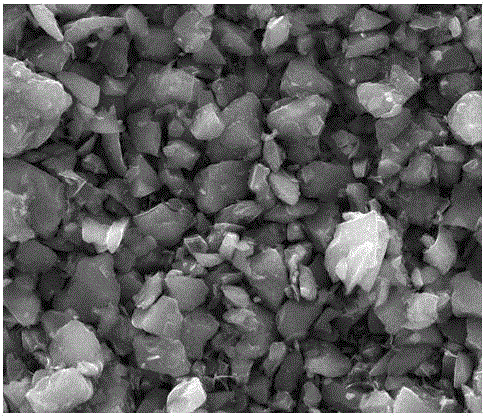

[0038] See attached figure 1 and 2 , which are the scanning electron micrograph and particle size distributio...

Embodiment 2

[0041] A preparation method of porous SiO core-shell microspheres, comprising the following steps:

[0042] (1) Preparation of porous SiOx

[0043] Configure 100 g of HF solution with a mass fraction of 6 wt%, and start stirring; slowly add 15 g of disproportionated SiO samples into the HF solution, stir for 1.5 h, filter and wash, and vacuum dry to obtain porous SiOx;

[0044] (2) Preparation of porous SiOx core-shell microspheres coated with epoxy resin

[0045] The obtained porous SiOx was ultrasonically dispersed with epoxy resin for 30 min, diluted with 11 g of chloroform, and 9 g of curing agent diethylaminopropylamine was added; the mixture was slowly added to an aqueous solution in which surfactant was dissolved, stirred and reacted at 55°C for 5 h, filtered and washed and vacuum drying to obtain porous SiOx core-shell microspheres coated with epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com