Preparation method and application of carbon/Fe3O4 composite material

A technology of ferroferric oxide and composite materials, which is applied in the field of one-step synthesis, can solve the problems of complex material synthesis route, complicated experimental process, and low yield, and achieve the effect of strong operability, simple process, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing a carbon / ferroferric oxide composite material, including the following steps:

[0042] A) After mixing the iron source and the liquid carbon source, a mixture is obtained, and then the mixture is heat-treated under airtight conditions to obtain a carbon / ferroferric oxide composite material.

[0043] The present invention does not have special restrictions on the iron source, as long as the conventional iron source is well known to those skilled in the art, those skilled in the art can select and adjust according to actual production conditions, product requirements and quality requirements. The present invention preferably includes divalent The iron source and / or the trivalent iron source, more preferably a divalent iron source or a trivalent iron source, more specifically preferably include one or more of ferric nitrate, ferrous nitrate, ferrous sulfate and ferric chloride, most Preferably, it is ferric nitrate or ferrous sulfat...

Embodiment 1

[0063] Weigh 1.616g Fe(NO 3 ) 3 ·9H 2 O, 0.3g polyacrylamide (PAM), after mixing, add 10ml absolute ethanol. Ultrasound for 30 minutes at room temperature, then transfer it to the reactor, seal it and place it in the crucible furnace, raise the temperature from room temperature to 600℃ at a heating rate of 6℃ / min for 10 hours, and collect the product after the reactor is naturally cooled to room temperature. The product is obtained after washing with a mixed solution of ethanol and water, a pure phase carbon / ferric oxide composite material.

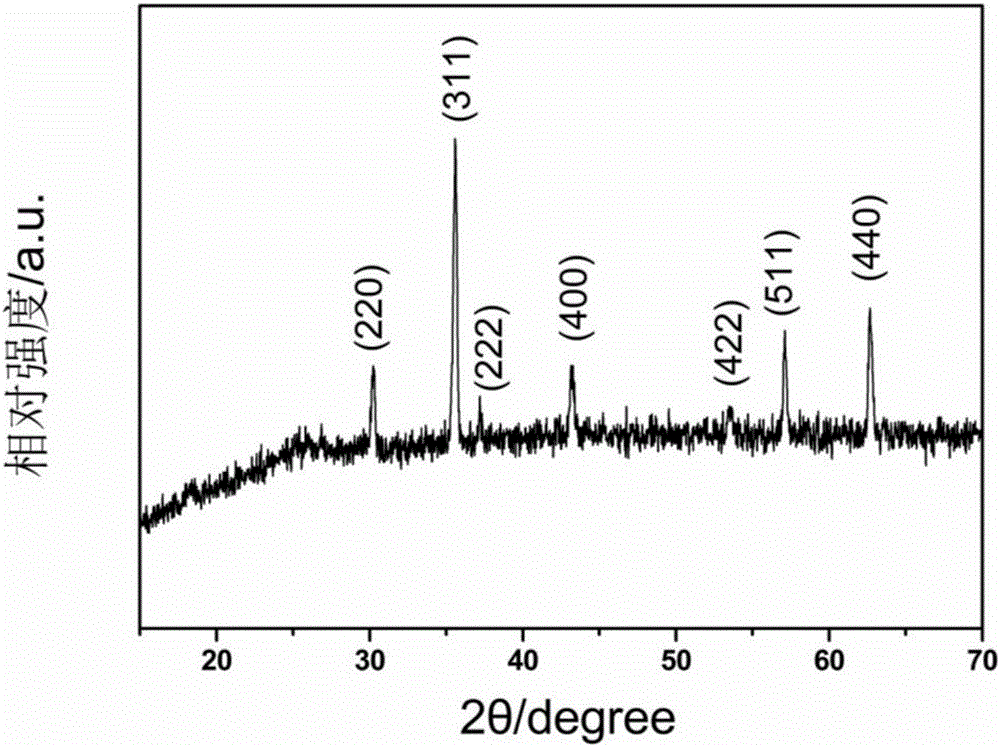

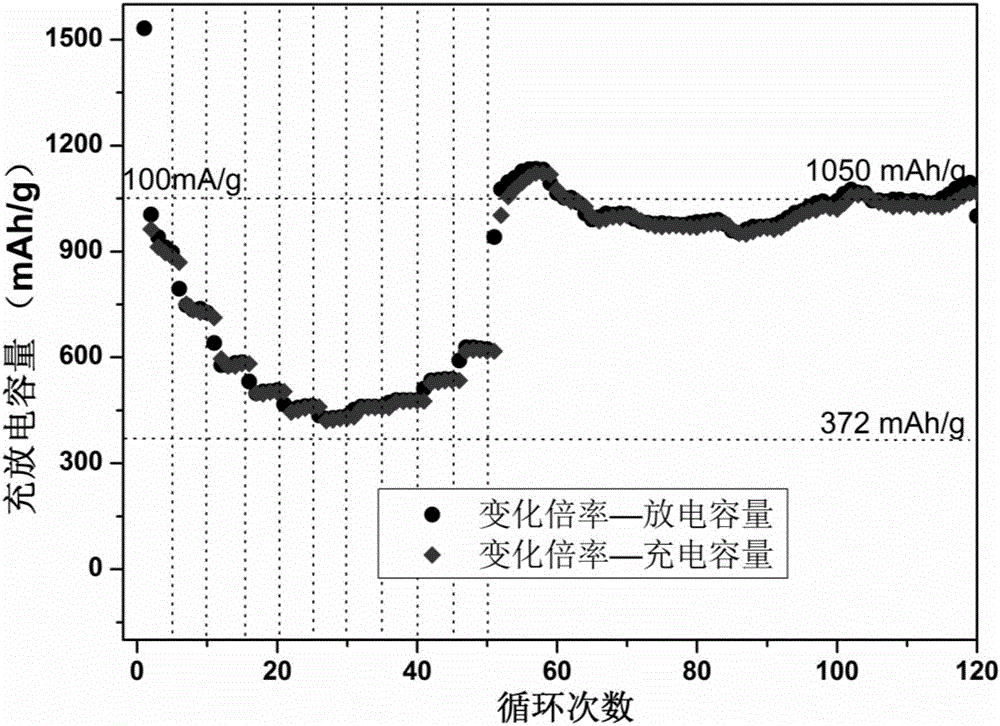

[0064] The carbon / ferric oxide composite material prepared in Example 1 of the present invention was characterized and analyzed.

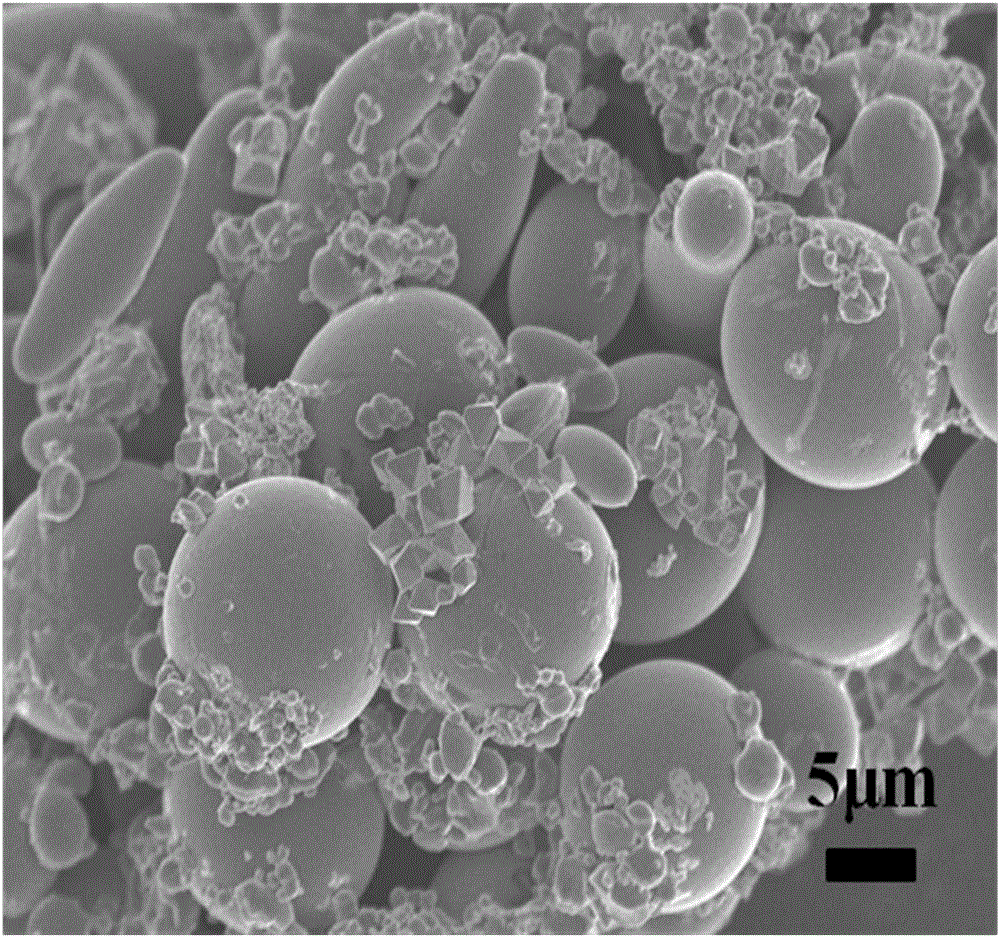

[0065] See figure 1 , figure 1 This is the SEM image of the carbon / ferric oxide composite material prepared in Example 1 of the present invention.

[0066] Analyzed by scanning electron microscopy: the product includes two parts, carbon balls and ferroferric oxide particles. The size of the carbon balls is 5-10μm, F...

Embodiment 2

[0082] Weigh 4.04g Fe(NO 3 ) 3 ·9H 2 O, pour 10ml absolute ethanol, add 0.3g PAM. The temperature rise procedure is the same as in Example 1. After the reactor is naturally cooled to room temperature, the product is collected, washed with a mixed solution of ethanol and water to obtain the product, a pure phase carbon / ferric oxide composite material.

[0083] The carbon / ferric oxide composite material prepared in Example 2 of the present invention was characterized and analyzed.

[0084] See Image 6 , Image 6 This is the SEM image of the carbon / ferric oxide composite material prepared in Example 2 of the present invention.

[0085] Analyzed by scanning electron microscopy: the product includes two parts, carbon balls and ferroferric oxide particles. The carbon content is reduced (the addition of iron source increases, the generated iron oxide increases), ferroferric oxide particles tend to be octahedral, and the particles The size increases to ~2μm.

[0086] The reason for the anal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com