Modified lithium-rich manganese-based positive electrode material and preparation method thereof

A lithium-rich manganese-based, cathode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of low discharge capacity, low first Coulomb efficiency, and reduce first irreversible capacity loss, etc., to improve Coulomb efficiency, The effect of complete crystal structure and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

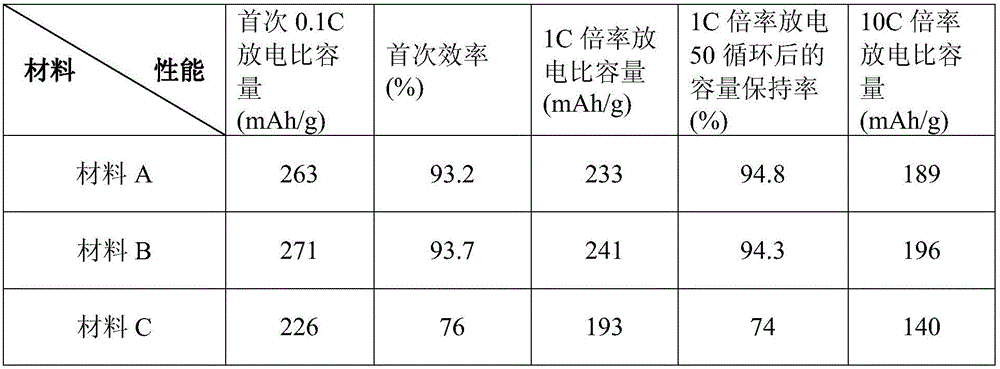

Examples

Embodiment 1

[0025] The lithium-rich manganese precursor Ni x co y mn z (OH) 2 (x:y:z=1:1:4) Pretreatment is carried out in the muffle furnace, the holding temperature is set at 400°C, the heating rate is 2°C / min, the holding time is 6h, the atmosphere is air, and the air flow rate is 10L / min, to obtain the pretreatment precursor;

[0026] Will Li 2 CO 3 , Li 2 RuO 3 , Lithium-rich manganese precursor after step 1 treatment, dopant AlF 3 Mix uniformly according to the molar ratio of 0.55:0.1:1:0.05, the obtained powder is sintered in a muffle furnace, the holding temperature is 750°C, the holding time is 12h, the heating rate is 5°C / min, the atmosphere is air, and the ventilation rate is 15L / min, after sintering, cool with the furnace at a cooling rate of 3°C / min, grind and sieve the sintered product, and obtain the final lithium-rich manganese-based positive electrode material A.

Embodiment 2

[0028] The lithium-rich manganese precursor Ni x co y mn z (OH) 2 (x:y:z=1:1:4) Carry out pretreatment in the muffle furnace, set the holding temperature at 600°C, the heating rate at 3°C / min, the holding time at 3h, the atmosphere is air, and the air flow rate is 15L / min, to obtain the pretreatment precursor;

[0029] Will Li 2 CO 3 , Li 2 RuO 3 , Lithium-rich manganese precursor after step 1 treatment, dopant AlF 3 Mix uniformly according to the molar ratio of 0.6:0.15:1:0.1, the obtained powder is sintered in a muffle furnace, the holding temperature is 850°C, the holding time is 10h, the heating rate is 5°C / min, the atmosphere is air, and the ventilation rate is 15L / min, after sintering, cool with the furnace at a cooling rate of 3°C / min, grind and sieve the sintered product to obtain the final lithium-rich manganese-based positive electrode material B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com